Patents

Literature

30results about How to "Neat seams" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

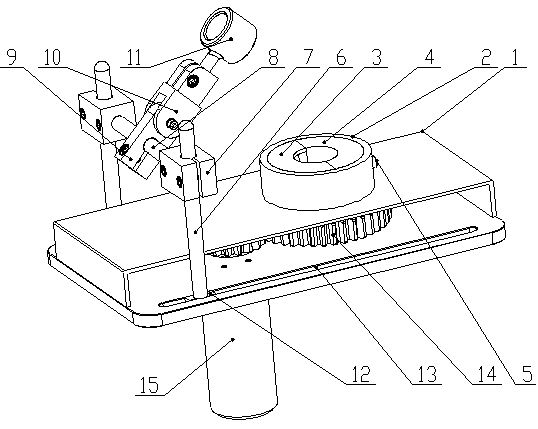

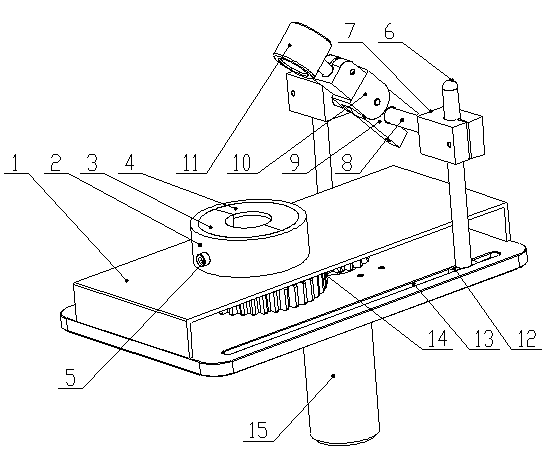

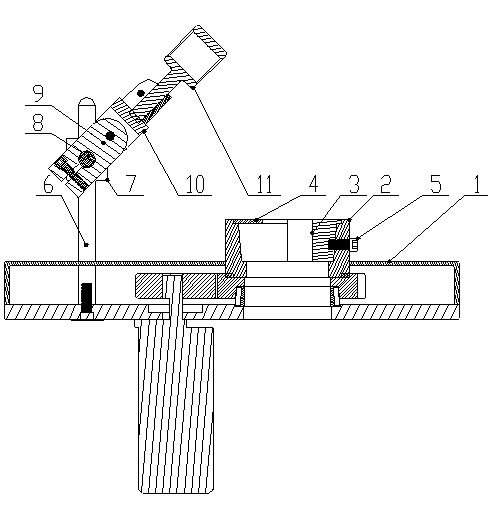

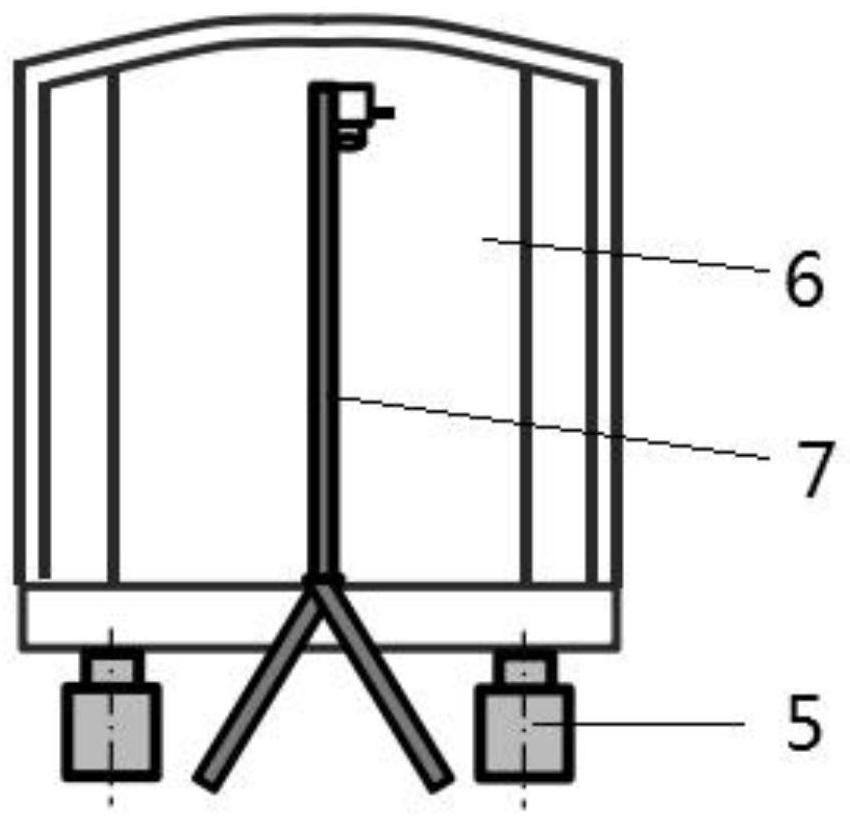

Efficient shape welding machine and using method thereof

InactiveCN103008942AQuick welding jobConvenient welding workWelding/cutting auxillary devicesAuxillary welding devicesDrive motorEngineering

The invention relates to an efficient shape welding machine and a using method thereof. The efficient shape welding machine comprises a working platform, wherein a rotary barrel is arranged on the working platform; a magnet of which the section is circular-arc-shaped is arranged in the rotary barrel, so that the outer circumferential wall of a welded part is fixed on the inner side arc face of the magnet; and a support frame for fixing a welding gun is arranged beside the rotary barrel. The method comprises the following steps of: I, adsorbing a welded part onto the inner circumferential wall of the magnet to realize fixing of the welded part; II, covering a separation blade for matching the separation blade with the magnet to sleeve the outer circumferential wall of the welded part; III, adjusting relative positions of a vertical rod, a first slide block and a swing stem to make a circular tube reach a corresponding position and position the welding gun erected on the circular tube at a welding position; and IV, starting the welding gun and a driving motor, wherein the driving motor is used for driving the rotary barrel to rotate for driving the welded part to rotate, and the welding gun is used for welding the welded part at the welding position through the driving motor, so that welding work of bent parts can be finished conveniently and rapidly.

Owner:江苏冠赛达工贸有限公司

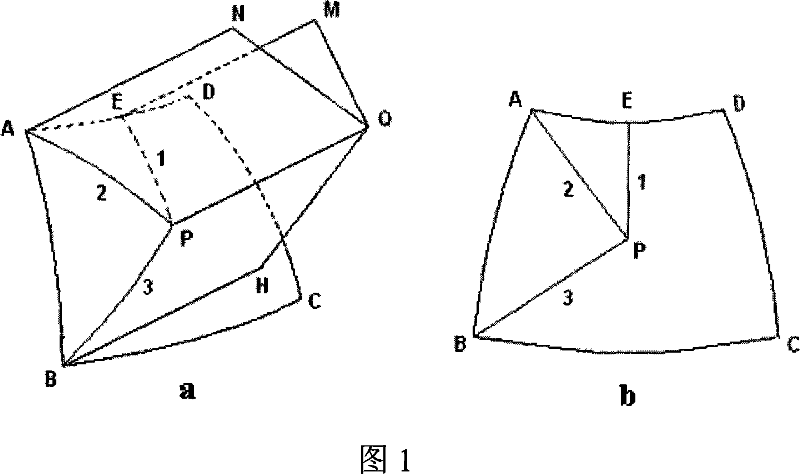

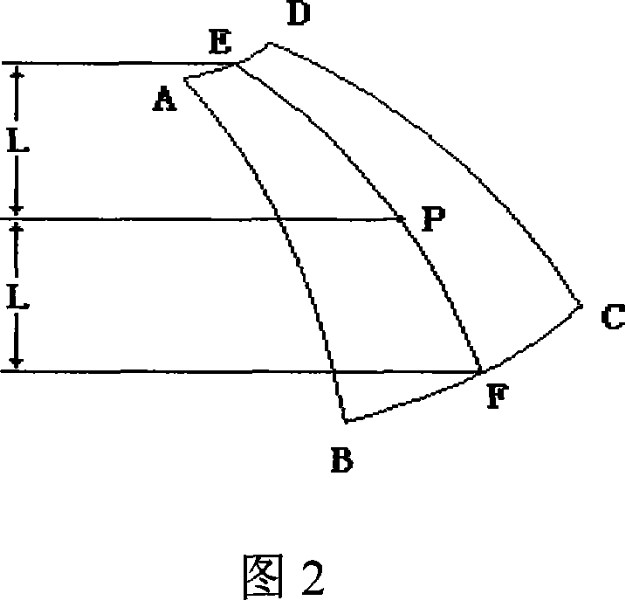

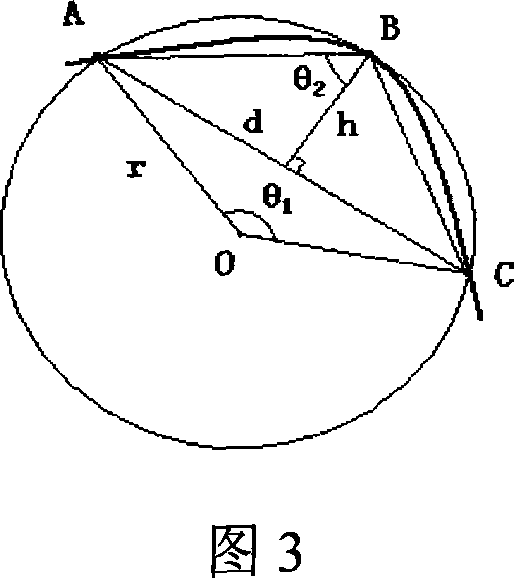

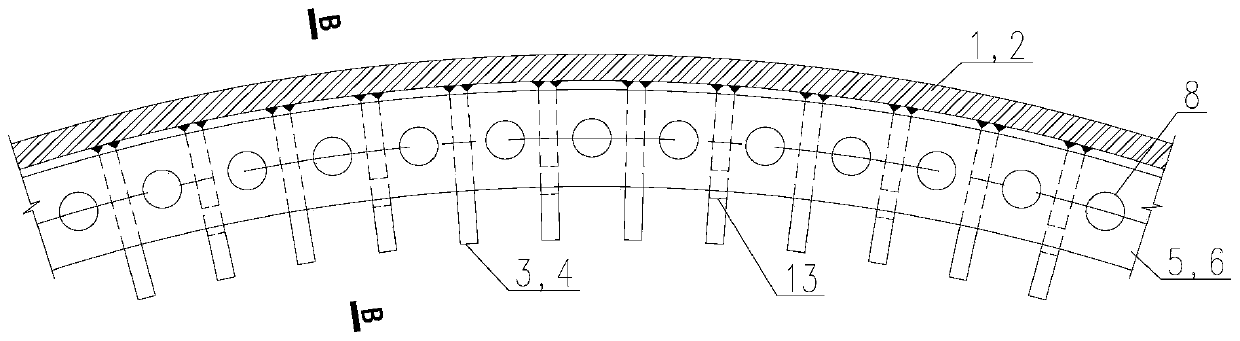

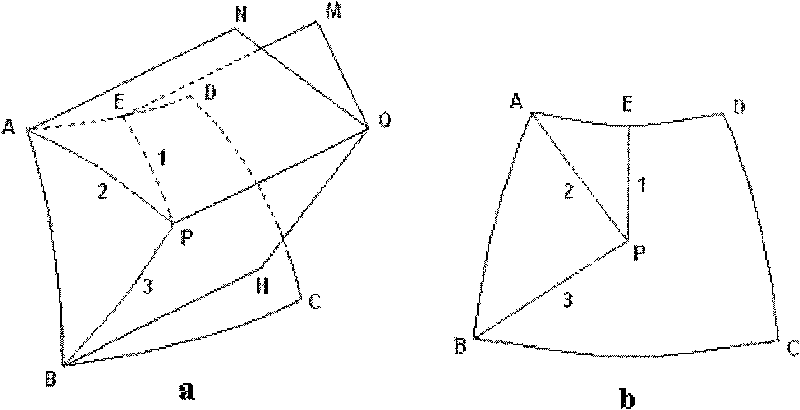

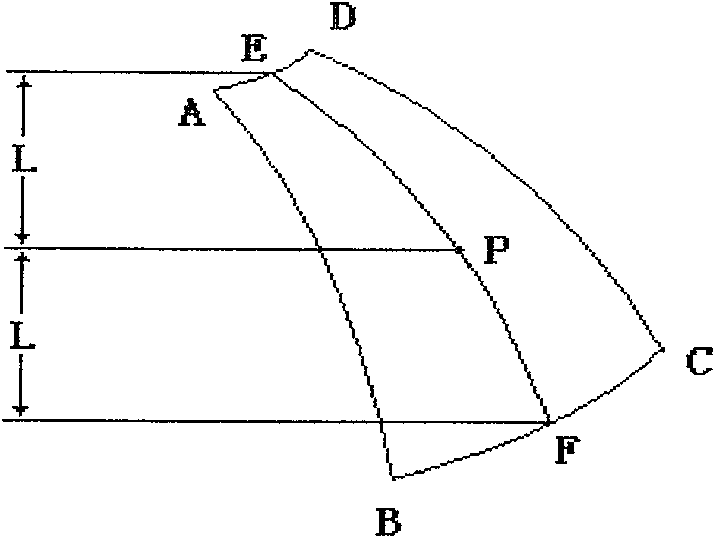

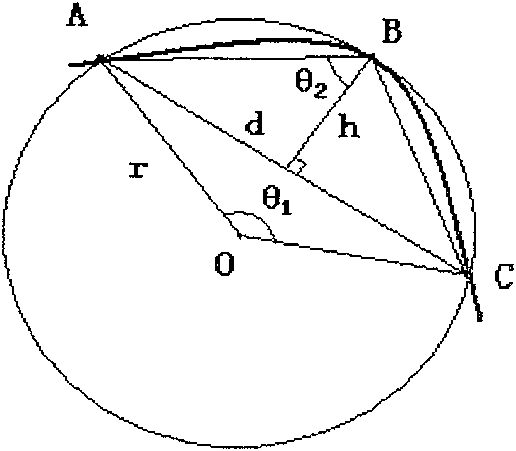

Assembling method for double curved surface metal curtain wall

The invention discloses an installment method of hyperboloid metal curtain wall, which comprises that first designs the spatial solid shape of the metal curtain wall, divides the shape into curvature blocks along longitude and woof, designs relative plane blocks based on the curvature blocks, feeds materials on the plane blocks, punches the plane blocks into relative curvature blocks, at last installs the curvatures into designed shape. The invention designs the size of plane block based on the curvature blocks via the equilateral distance method, to assure the engagement between the curvatures to obtain the high-quality joint between curvatures.

Owner:ZHEJIANG YASHA CURTAIN WALL

Continuous high-frequency welding machine and welding method

InactiveCN100460188CGuaranteed complete fusion bondingMake up for the problem of uneven local gapsEngineeringCopper

The present invention is developed on the basis of available continuous HF fusion welding machine and fusion welding method and has improved long non-ferrous metal electrode plate. Structurally, the present invention has flexible material inside the longitudinally open-mouthed section, conducting copper sheet on the flexible material and insulating layer on the conducting copper sheet; as well as wheel protecting belt below the movable HF electrode plate heat jointing and settling assembly. The present invention has the advantages of the complete fusion and adhering of the jointed material, no adhesion between the HF electrode plate heat jointing and settling assembly and the jointed material and high welding quality.

Owner:杭州中凌广告器材有限公司

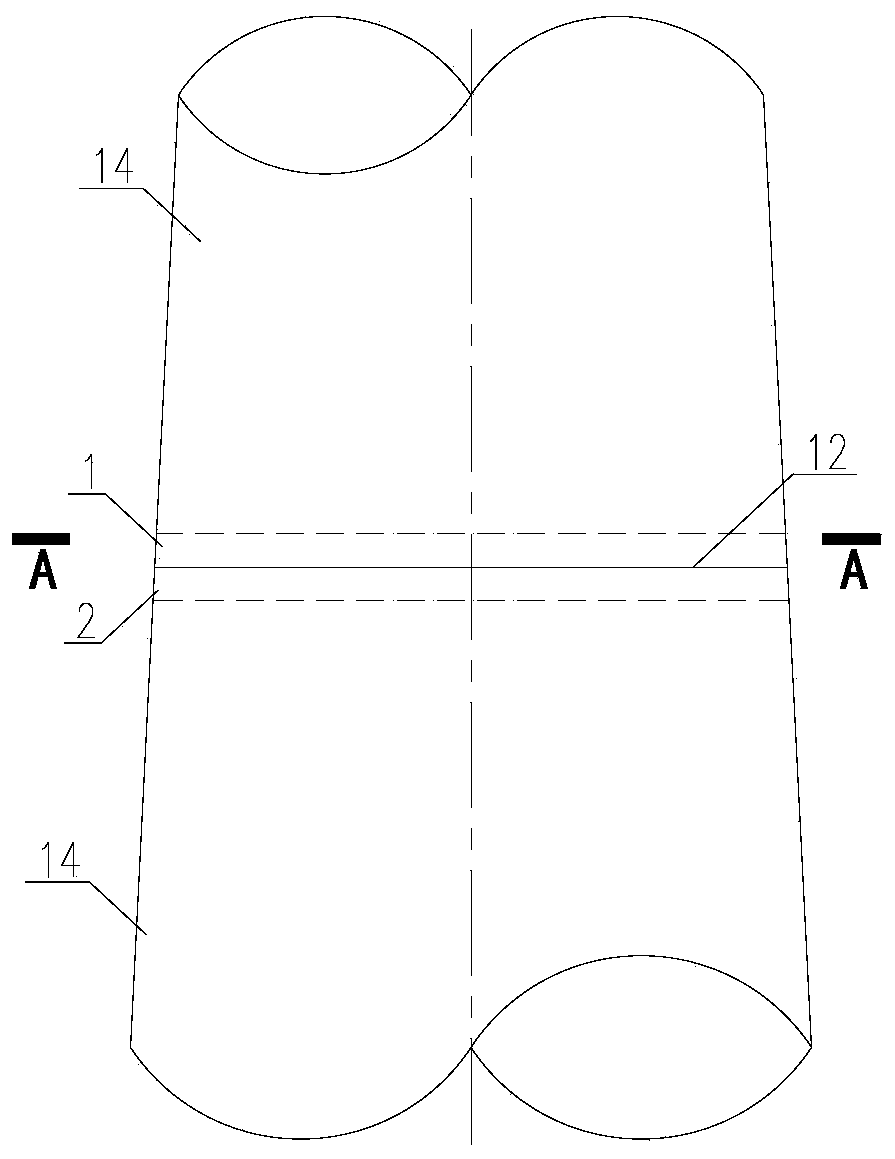

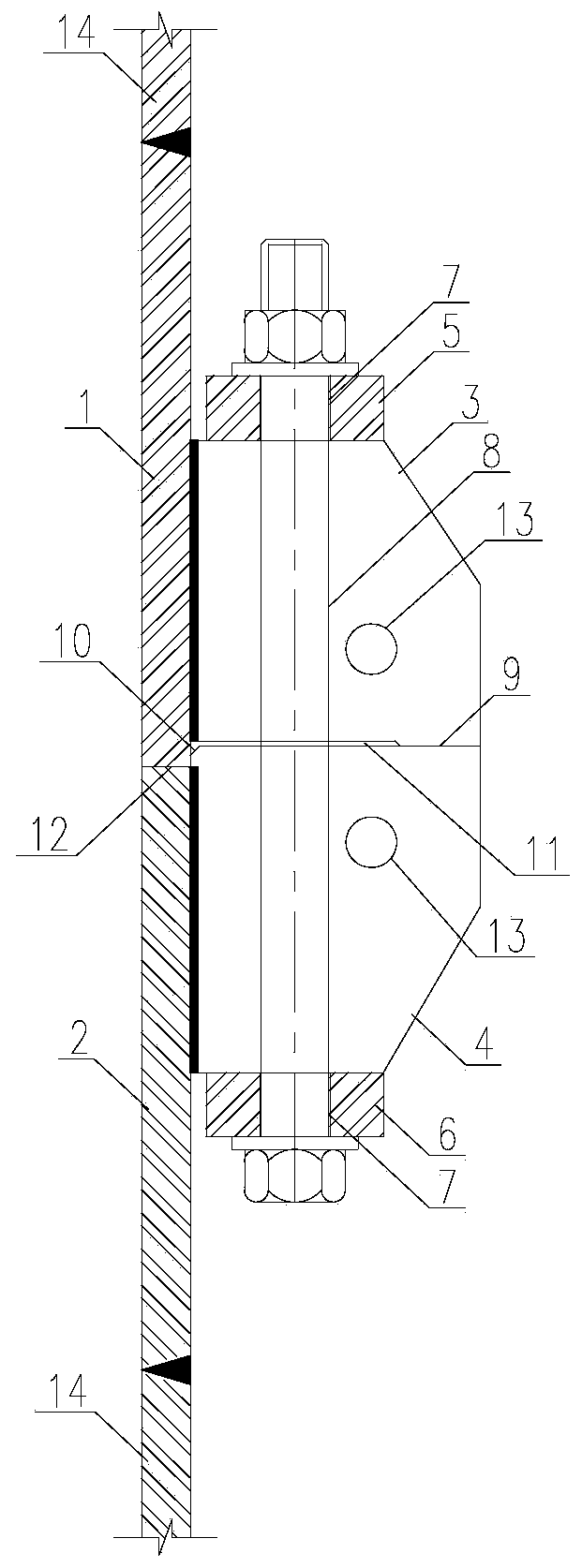

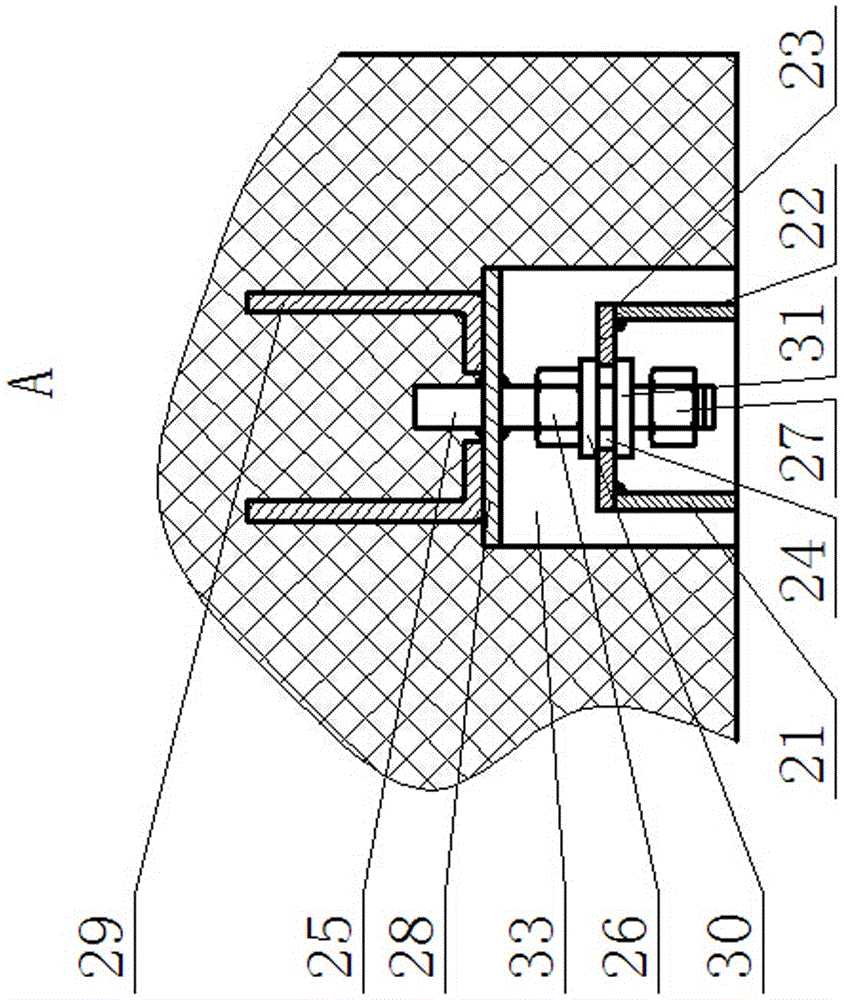

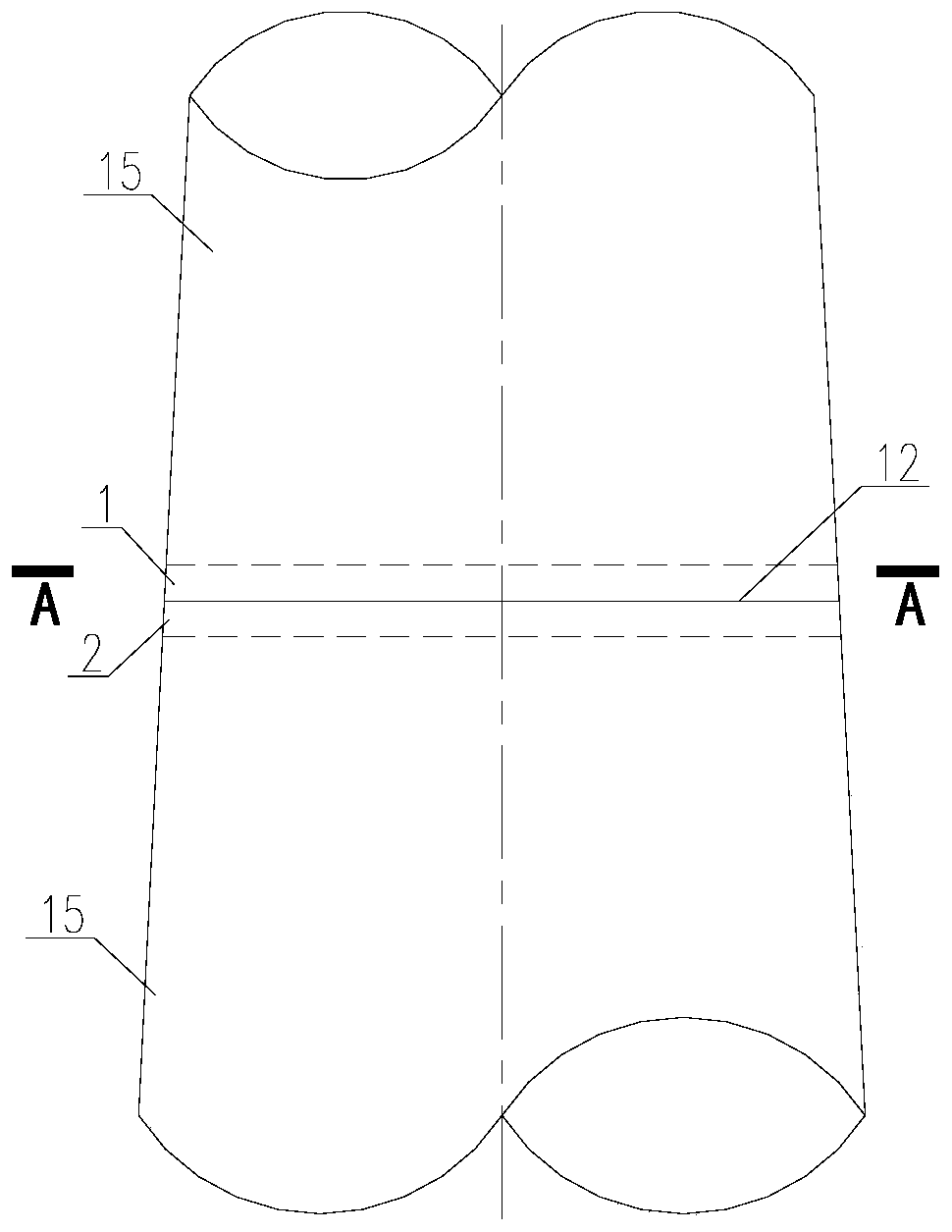

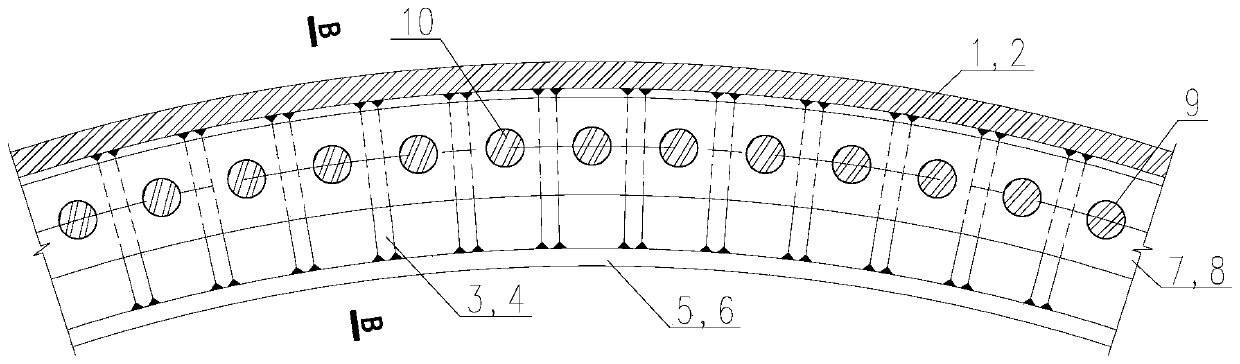

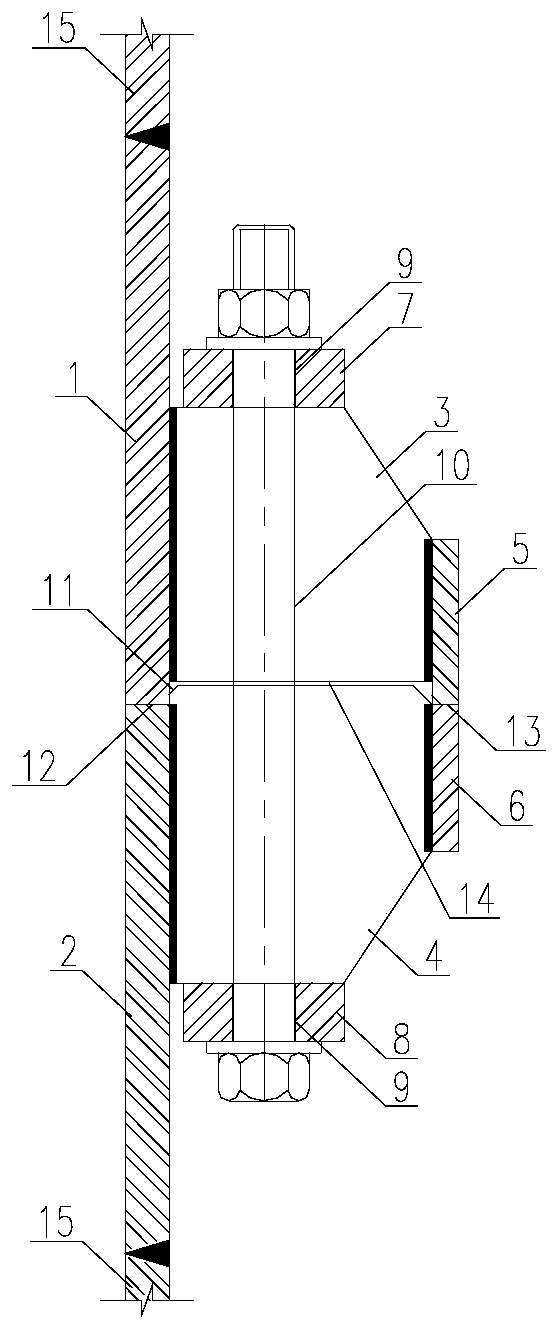

Counter balance flange joint and application thereof

PendingCN110671278AReduce processing difficultyIncreased bending stiffnessWind motor assemblyWind motor supports/mountsMachining processAdhesive

The invention relates to a counter balance flange joint, which includes an upper flange tower and a lower flange tower, wherein a propping stiffening plate is welded on the inner wall of the upper flange tower; a guiding stiffening plate is welded on the inner wall of the lower flange tower; an upper flange plate is connected with the upper surface of the propping stiffening plate through a structural adhesive; the lower surface of the guiding stiffening plate is connected with a lower flange plate through a structural adhesive; bolt holes are formed in the upper flange plate and the lower flange plate; high-strength bolts penetrate through the upper flange plate and the lower flange plate through the bolt holes, so as to connect the upper flange tower with the lower flange tower; mountingholes are formed in the propping stiffening plate and the guiding stiffening plate respectively; connecting rods clamped with the corresponding stiffening plates are arranged inside the mounting holes; the two connecting rods are fastened and connected with annular auxiliary mechanisms arranged on the inner sides of the propping stiffening plate and the guiding stiffening plate. Compared with theprior art, the counter balance flange joint has the advantages of low welding amount, simple machining technology, high tower anti-fatigue level and no deformation during transportation.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

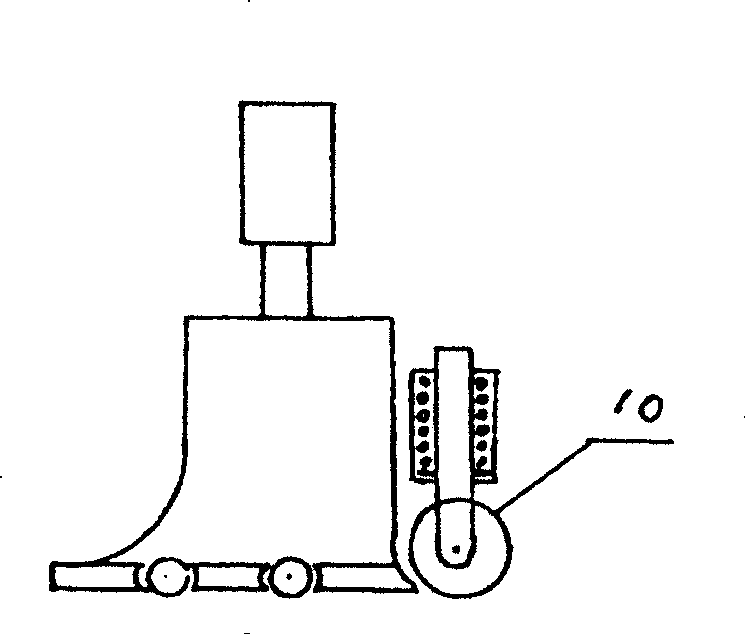

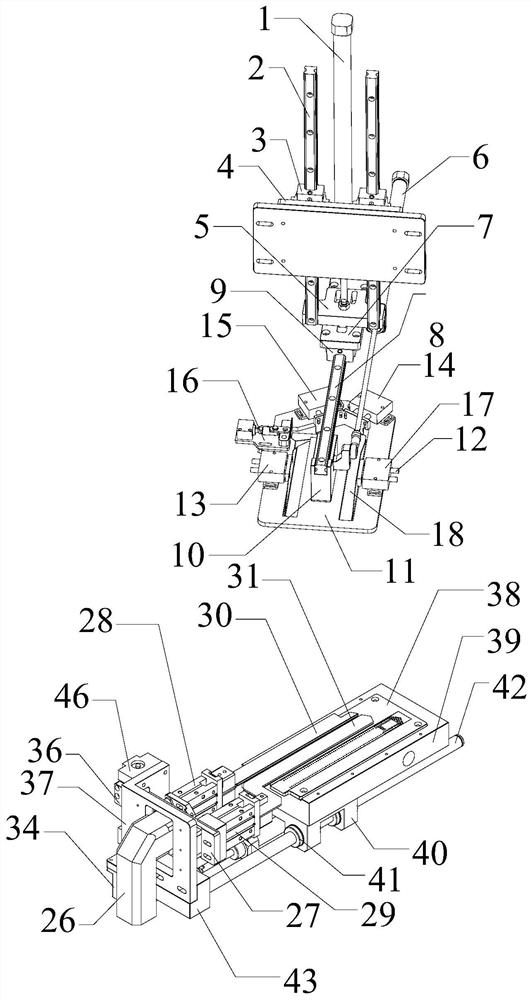

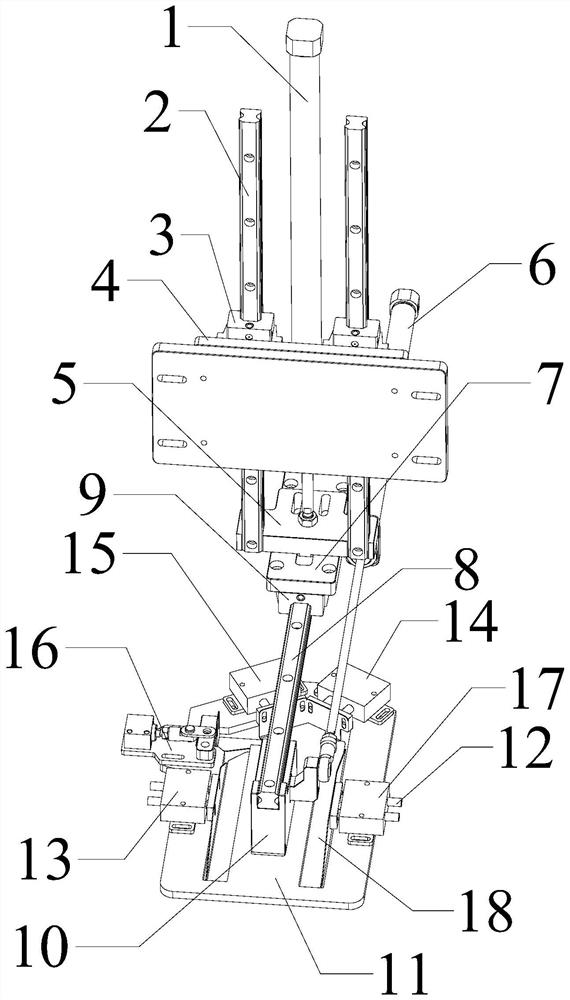

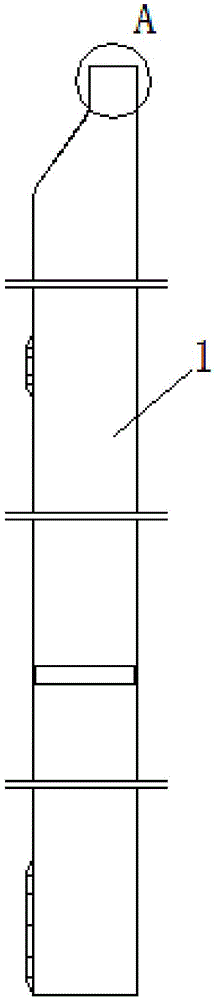

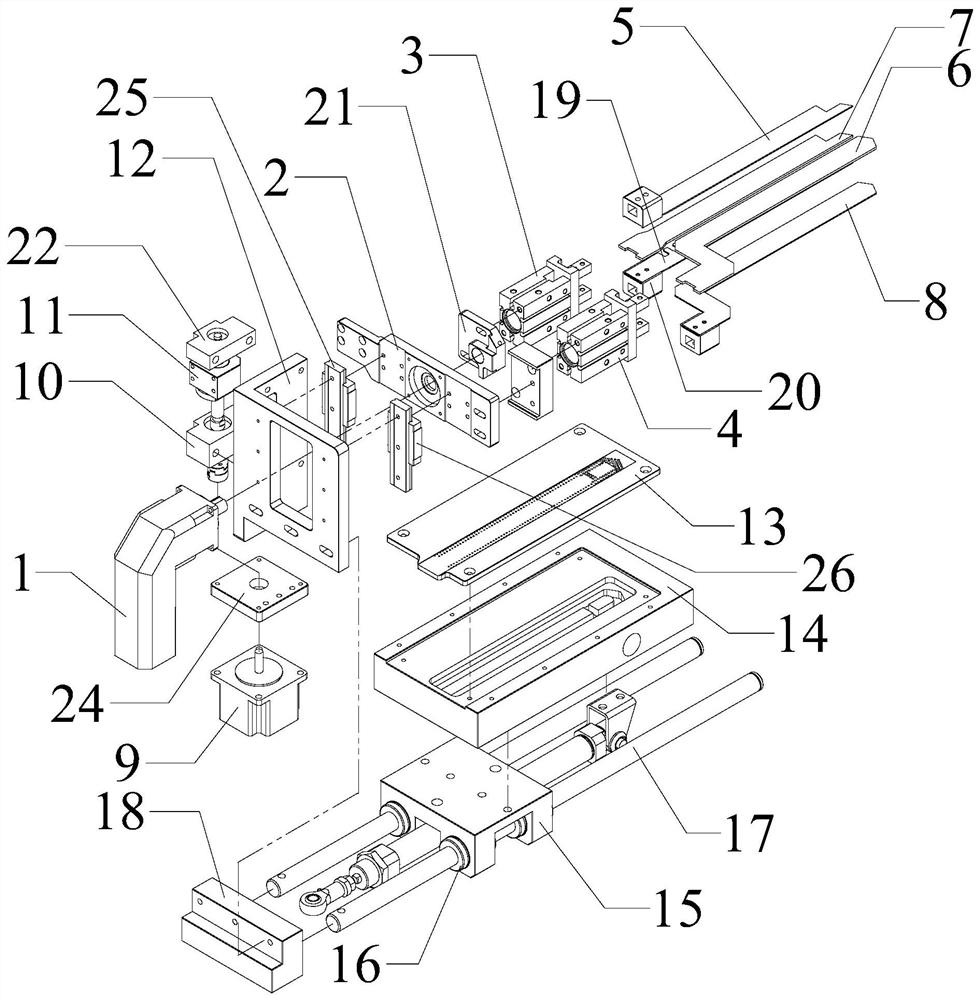

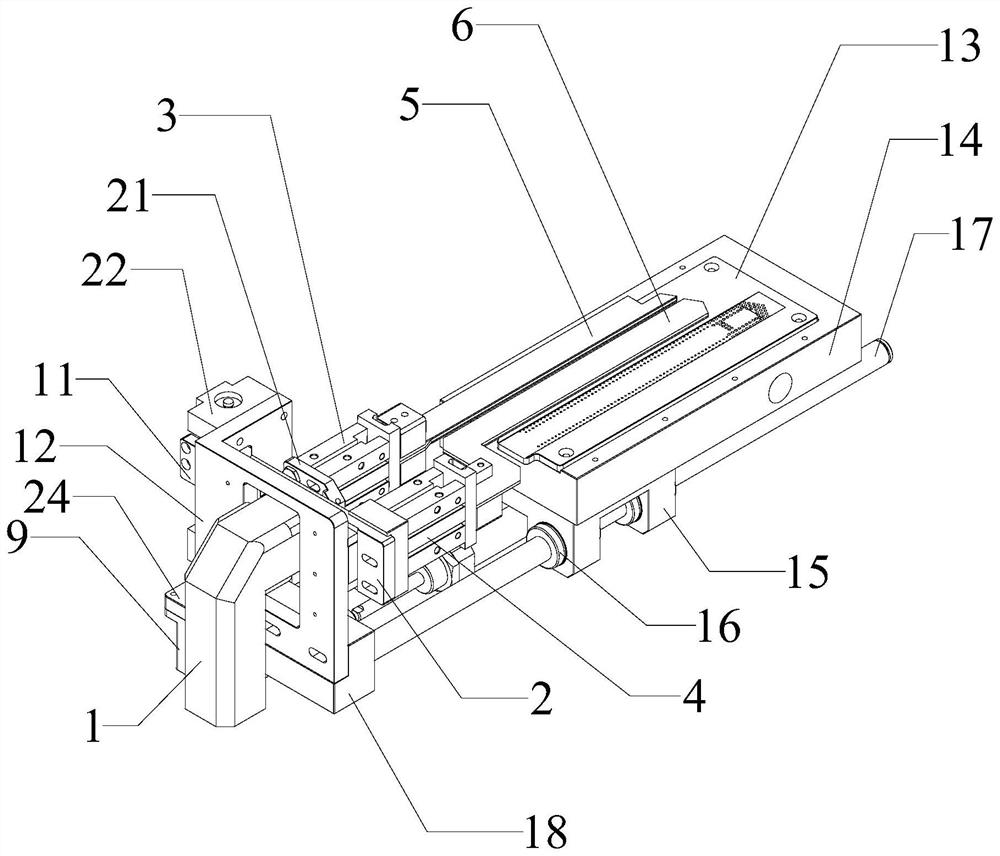

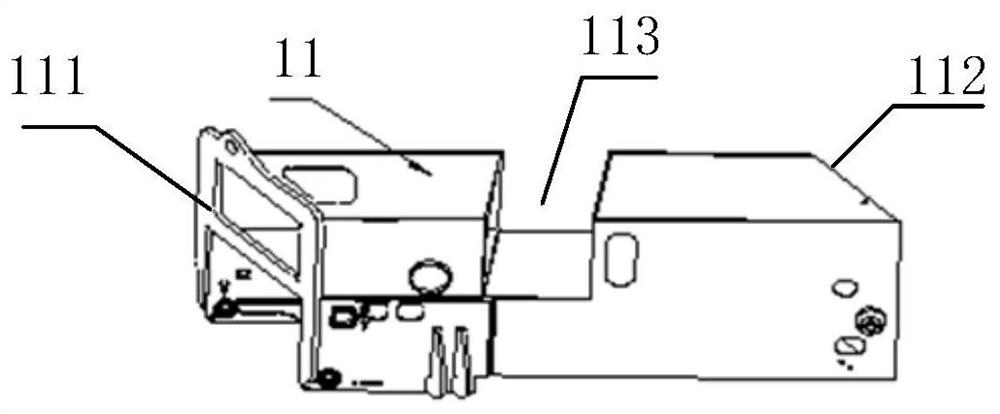

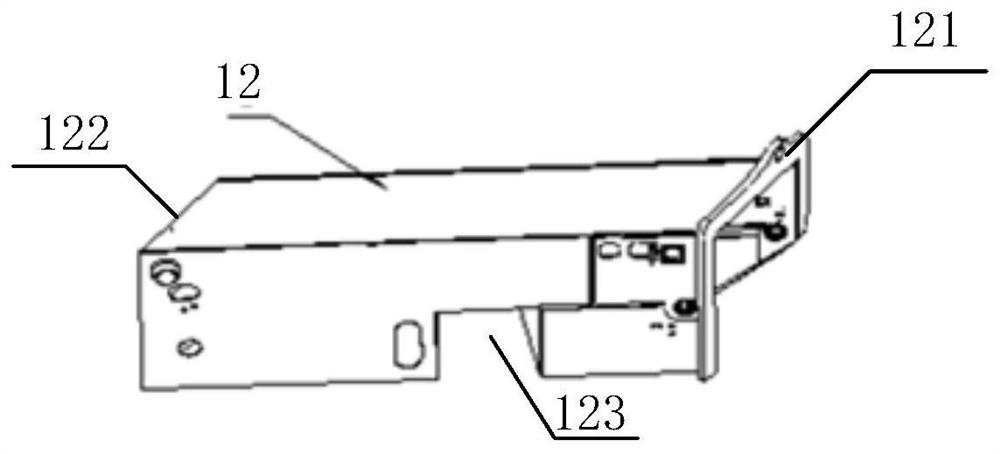

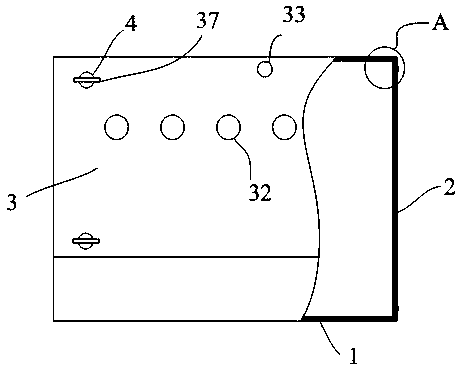

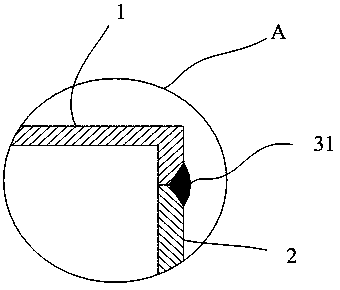

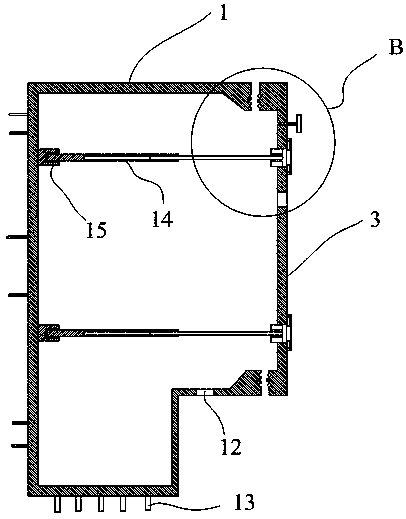

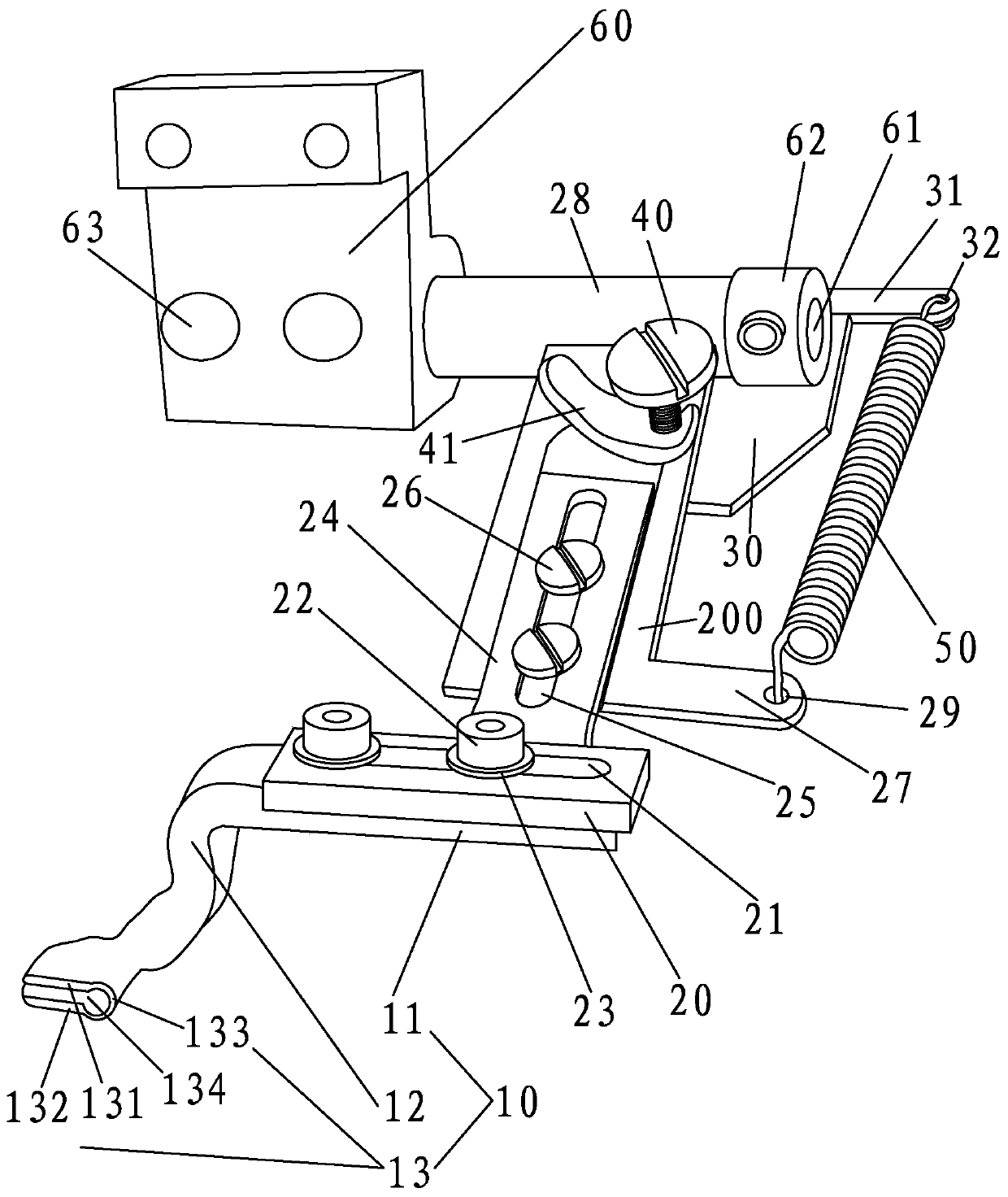

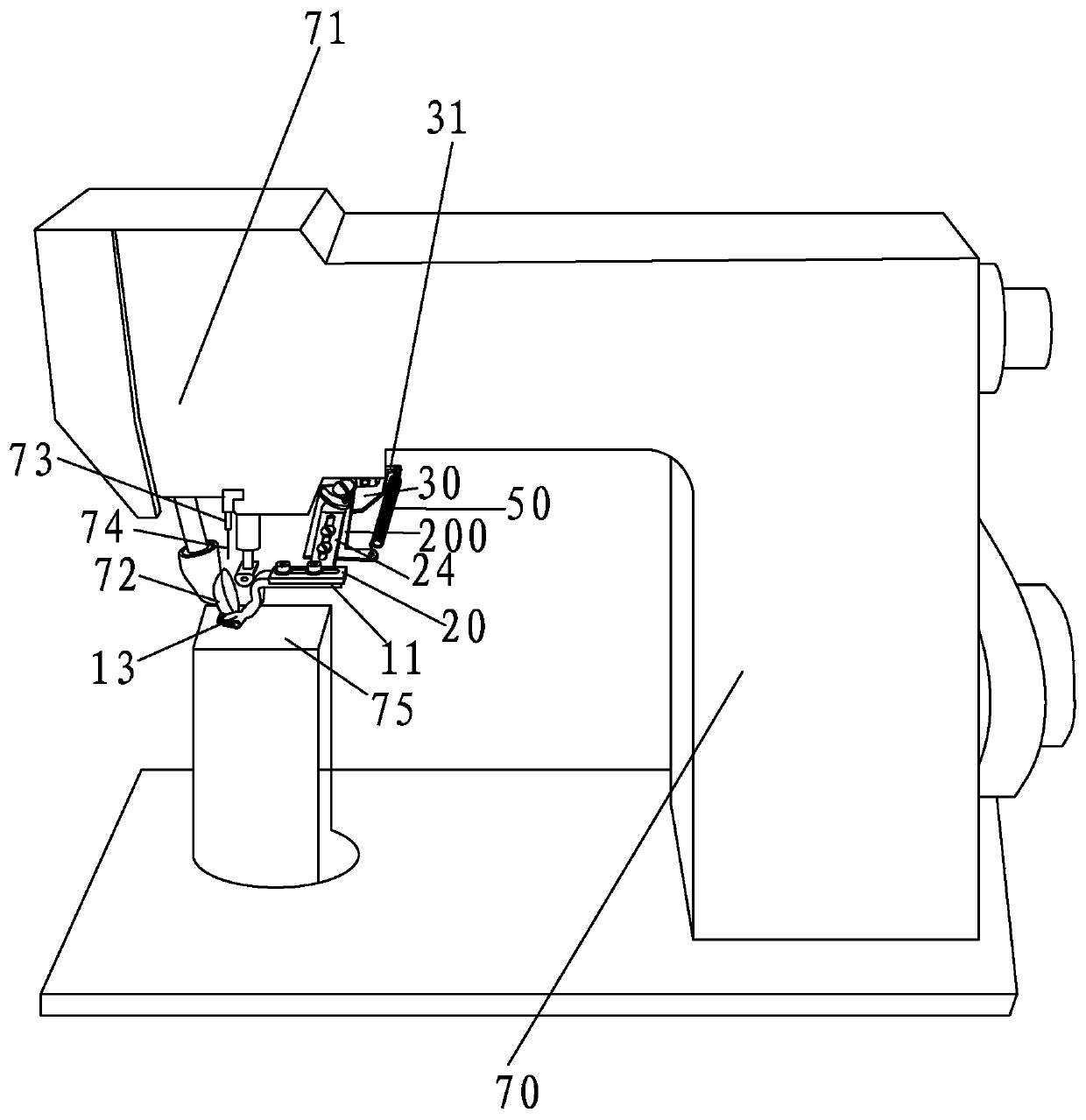

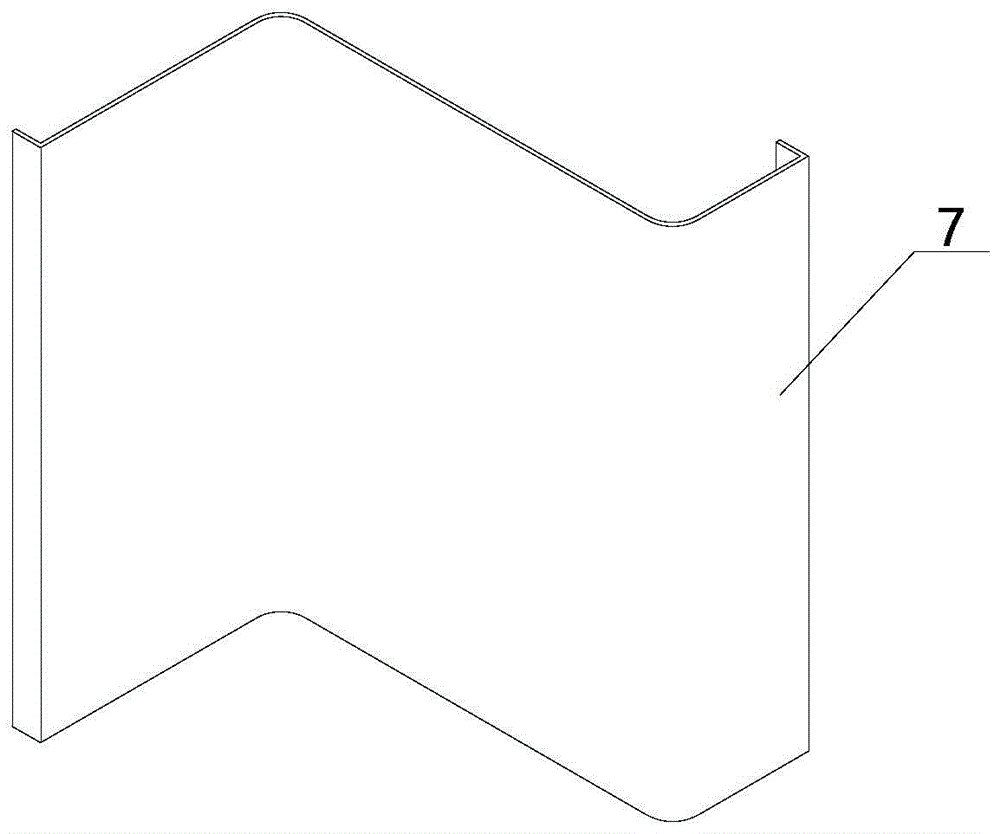

Folding and setting device of sleeve placket machine

PendingCN113355813ANo manual operation requiredImprove efficiencyWork-feeding meansAutomatic controlElectric machinery

The invention discloses a folding and setting device of a sleeve placket machine, and belongs to the technical field of sewing machines. The folding and setting device comprises an auxiliary folding and setting mechanism and a cloth folding and setting mechanism; the auxiliary folding and setting mechanism is provided with a first lifting assembly, a horizontal sliding assembly and a folding assembly; and the cloth folding and setting mechanism is provided with a folding assembly and a second lifting assembly. The folding and setting device has the beneficial effects that after the corner parts of sleeve placket cloth are subjected to auxiliary folding through an automatic control machine, the sleeve placket cloth is driven by an overturning motor to be overturned and folded downwards, and manual operation is not needed in the whole process, so that the working efficiency of the sleeve placket machine is improved, the labor cost can be saved, and the requirements of industrial production are met.

Owner:东莞市宝韵自动化设备有限公司

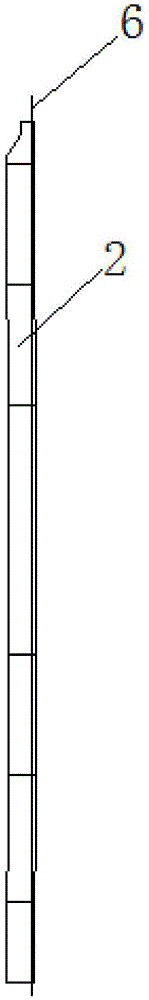

Building quake-proof outer wall hanging plate

ActiveCN105780972AReduced precision requirementsRaise the seamWallsArchitectural engineeringScrew thread

Owner:SHANDONG ONE STAR CO NSTRUCTION TECH CO LTD

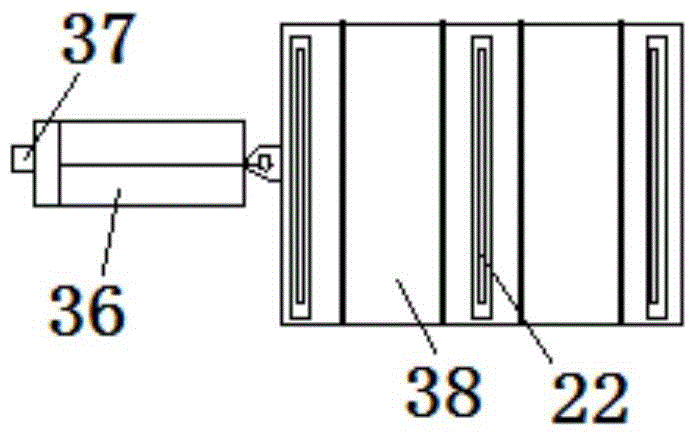

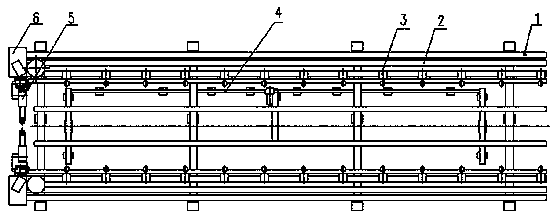

Crane main beam and machining method thereof

ActiveCN105540429AImprove rigidityAvoid deflectionLoad-engaging girdersWelding apparatusEngineeringMachining

The invention discloses a crane main beam. The crane main beam comprises a first web, a second web, reinforced frames, a top plate and a bottom plate. The top plate is connected with the top of the first web, and the bottom plate is connected with the bottom of the second web. The reinforced frames are arranged in the main beam at intervals and are fixedly connected with the first web, the second web, the top plate and the bottom plate respectively. The first web and the second web are each provided with a camber. The first web and the second web are both formed in a sequence welding manner. Staggering distances are set between segmented weld joints of the first web and between segmented weld joints of the second web. Due to the fact that the first web and the second web of the main beam are formed in the sequence welding manner and a certain staggering distance is kept between every two adjacent segmented weld joints of the two webs, stress of the main beam is dispersed because of arrangement of the weld joints; due to a new machining technology, the rigidity of the main beam is enhanced, and flexibility caused when a long-span main beam generates bending moment because of dead weight is effectively prevented.

Owner:CHANGZHOU CHANGKUANG HOISTING MACHINERY

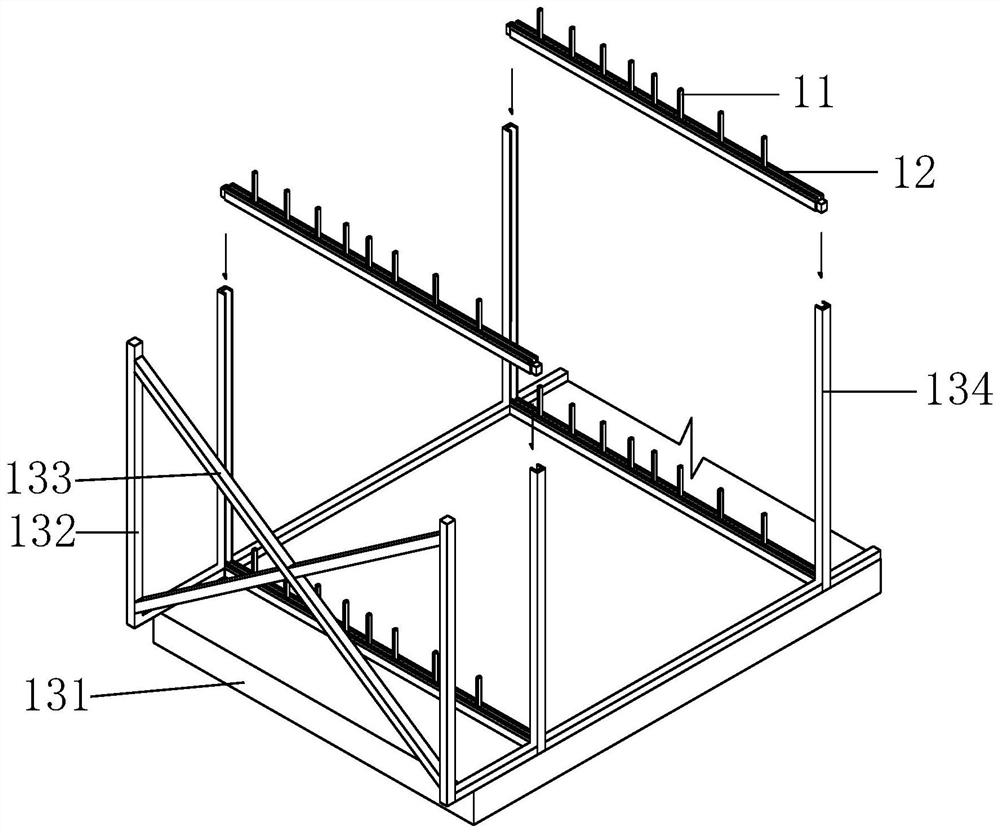

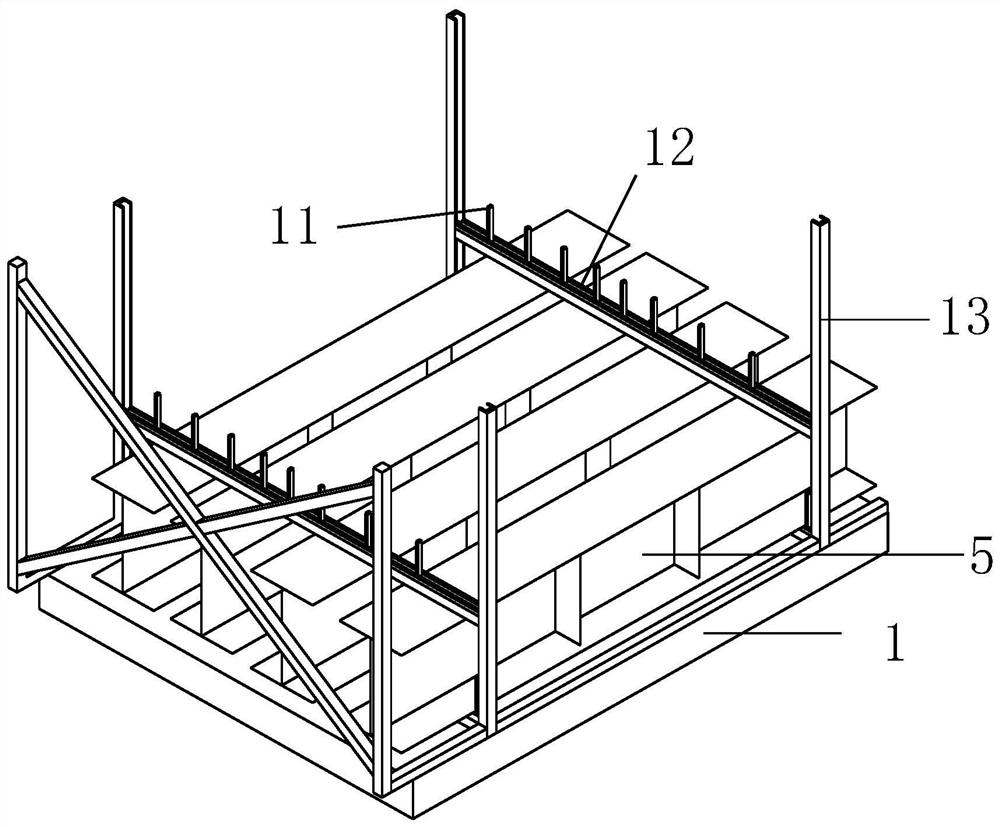

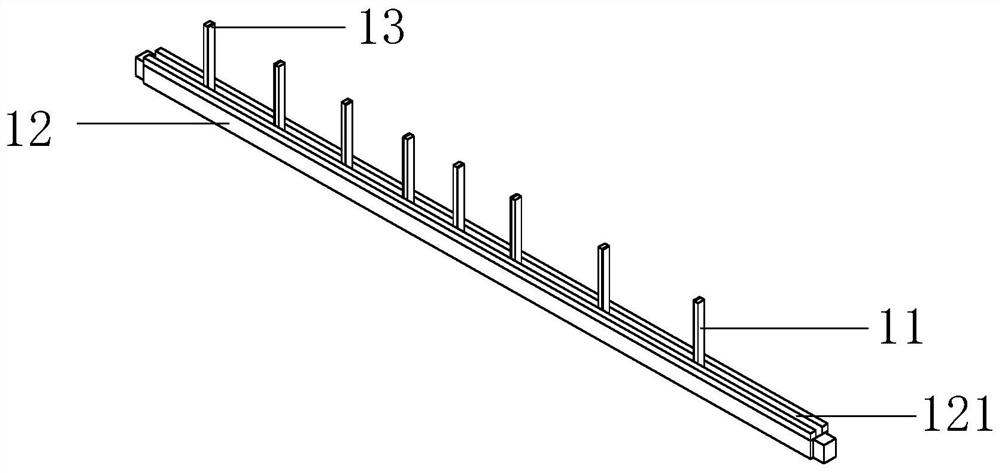

Steel box tied-arch bridge steel structure construction system and method

PendingCN112609583APrevent dumpingAvoid bump damageBridge erection/assemblyArch-type bridgeSupporting systemArchitectural engineering

The invention provides a steel box tied-arch bridge steel structure construction system and method, a transportation isolation protection support is additionally arranged in the transportation process of steel beam components, and the quality and transportation safety of the steel beam components are guaranteed; according to a temporary support system, steel pipe columns are directly connected with the strip-shaped foundation embedded parts through connecting sleeves, meanwhile, the steel pipe columns are anchored with one another through unit type sliding connecting parts, an integral type steel frame is arranged at the top, and the whole temporary support system is high in building speed and good in stability; the fixed steel beam components are finely adjusted through a steel beam component splicing position adjusting device composed of an L-shaped steel plates and a jack, so that it is guaranteed that joints are tidy, the elevation is proper, the waste of raw materials is reduced, and the mounting precision and quality of the steel beam components are greatly improved. A temporary fixing system is formed between the installed steel beam components and the installed steel structure through horse plates and clamps on the two sides, and the time needed by hoisting and splicing work is greatly shortened.

Owner:ANHUI ROAD & BRIDGE GRP

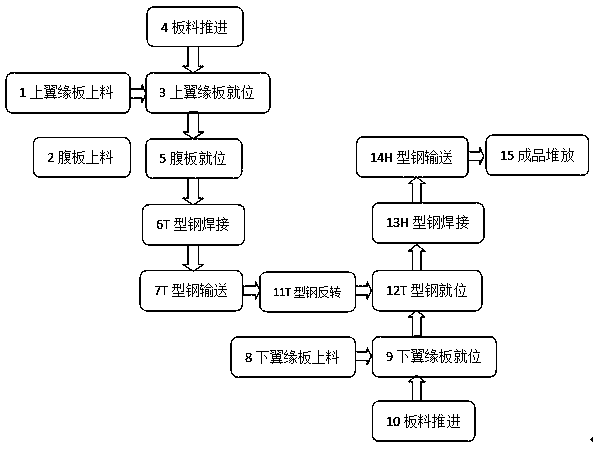

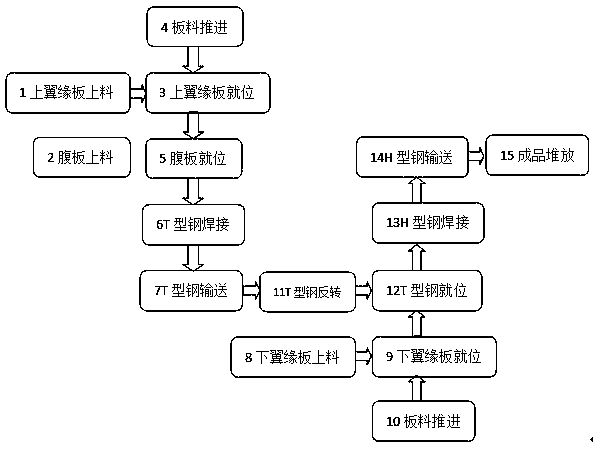

Automatic submerged-arc welded H-shaped steel production method

InactiveCN109967841ARealize continuous automatic welding productionContinuous automatic welding production is convenientArc welding apparatusSheet steelEngineering

The invention relates to an automatic submerged-arc welded H-shaped steel production method. The method comprises the following steps of feeding, upper flange plate pushing and cutting, upper flange plate conveying, web pushing and cutting, web turning over, upper flange plate secondary conveying, T-shaped steel automatic welding, lower flange plate pushing and cutting, lower flange plate conveying, T-shaped steel conveying, T-shaped steel turning over, lower flange plate secondary conveying, H-shaped steel automatic welding, finished product conveying, and finished product stacking and packaging; and feeding is conducted through a portal crane, the steel is cut through a plasma cutting trolley, steel plates and finished products are conveyed, stacked and packaged through a conveying platform, a finished product conveying system, a finished product stacking and packaging system. The automatic submerged-arc welded H-shaped steel production method has the advantages of being easy and convenient to operate, stabile in connection and capable of achieving continuous automatic production.

Owner:LUANXIAN ZHONGXING STEEL STRUCTURE

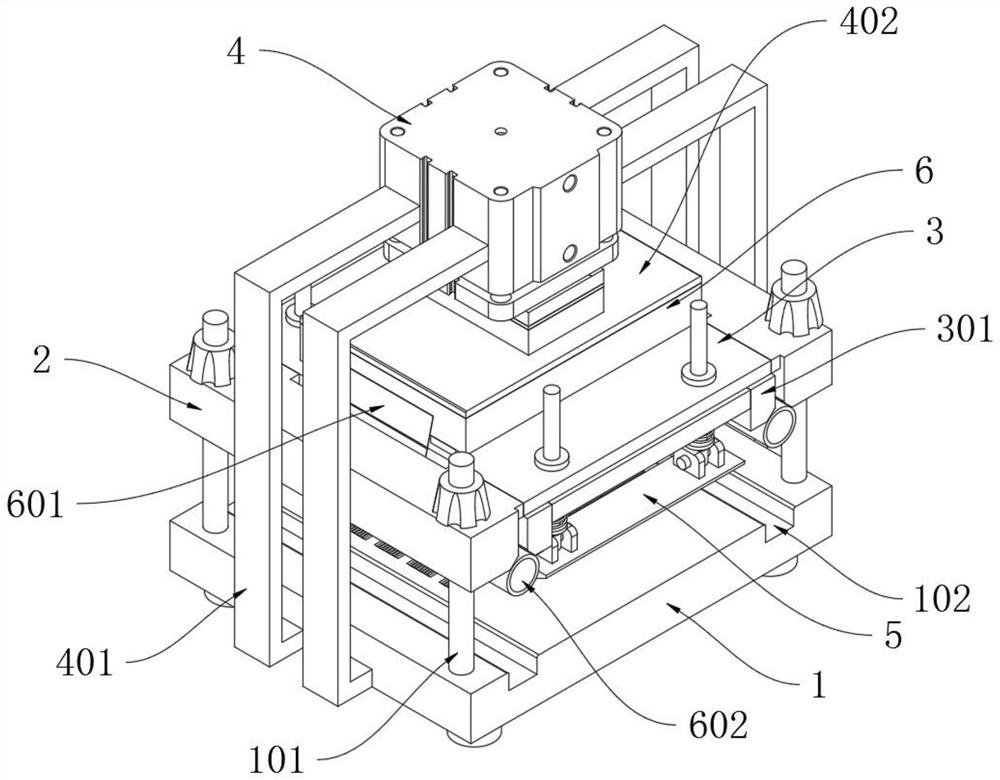

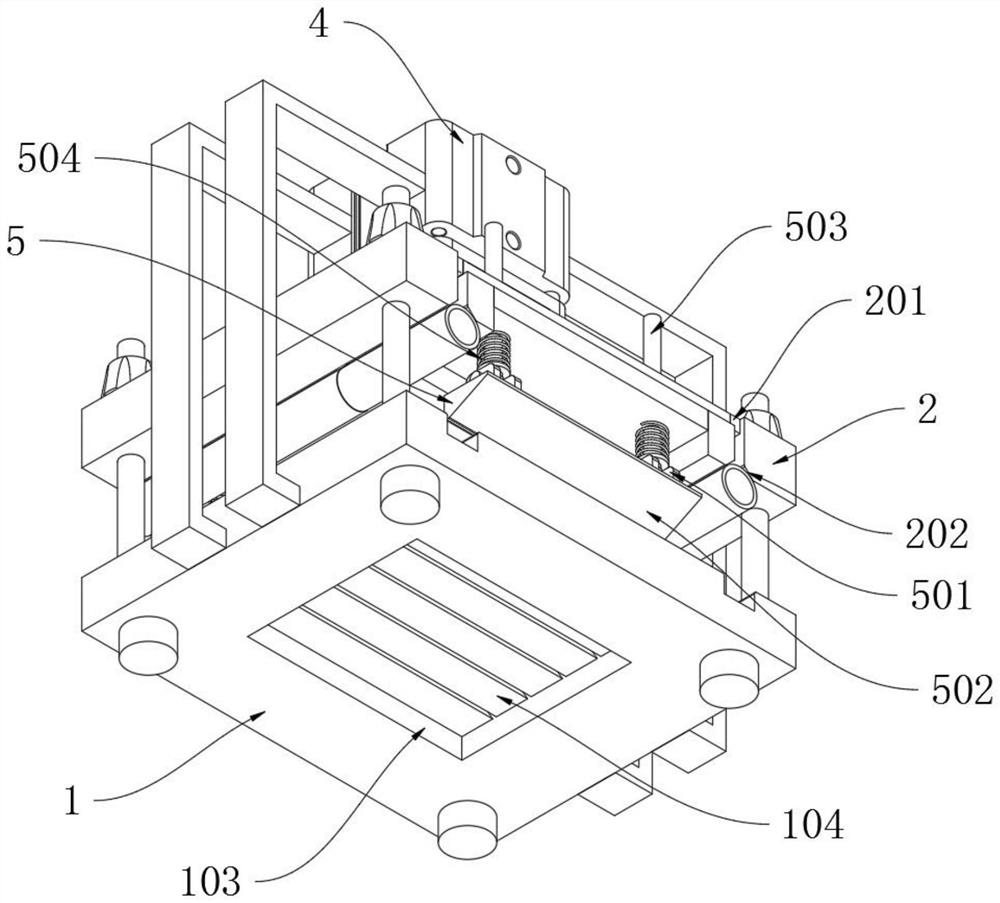

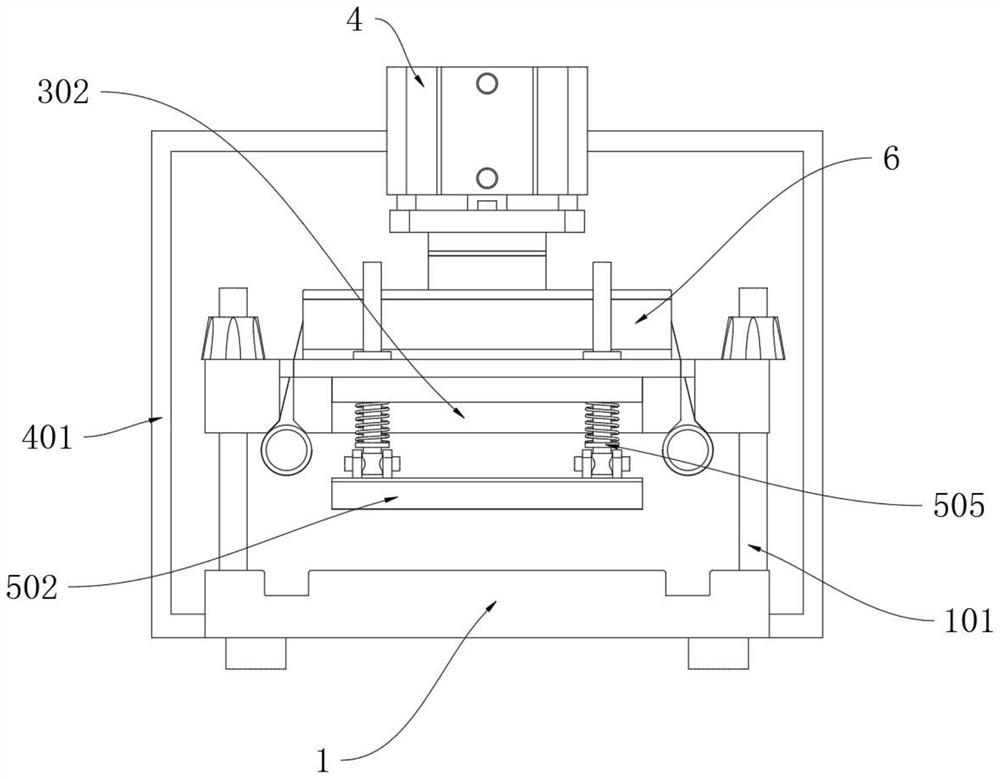

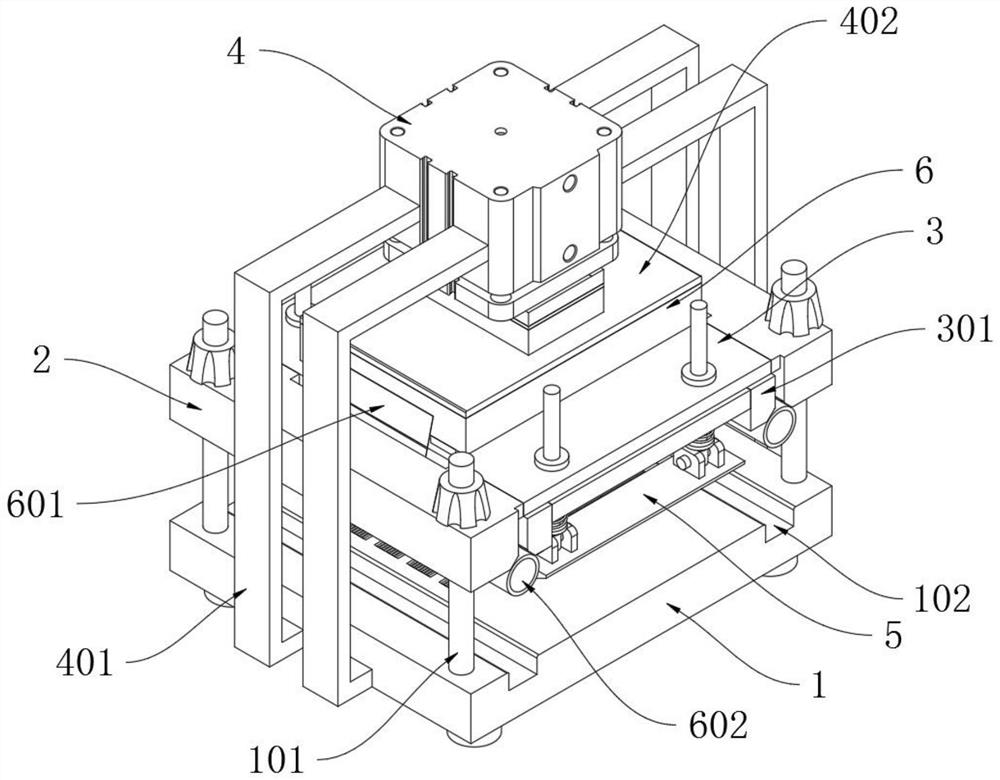

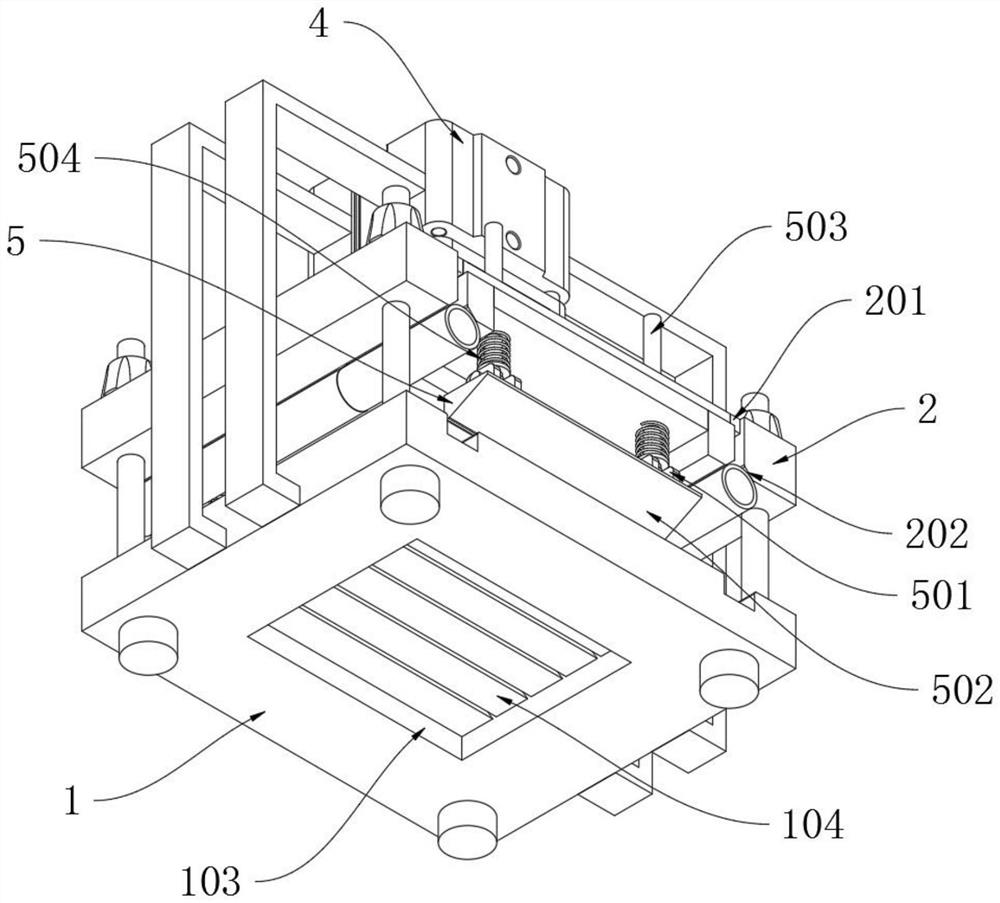

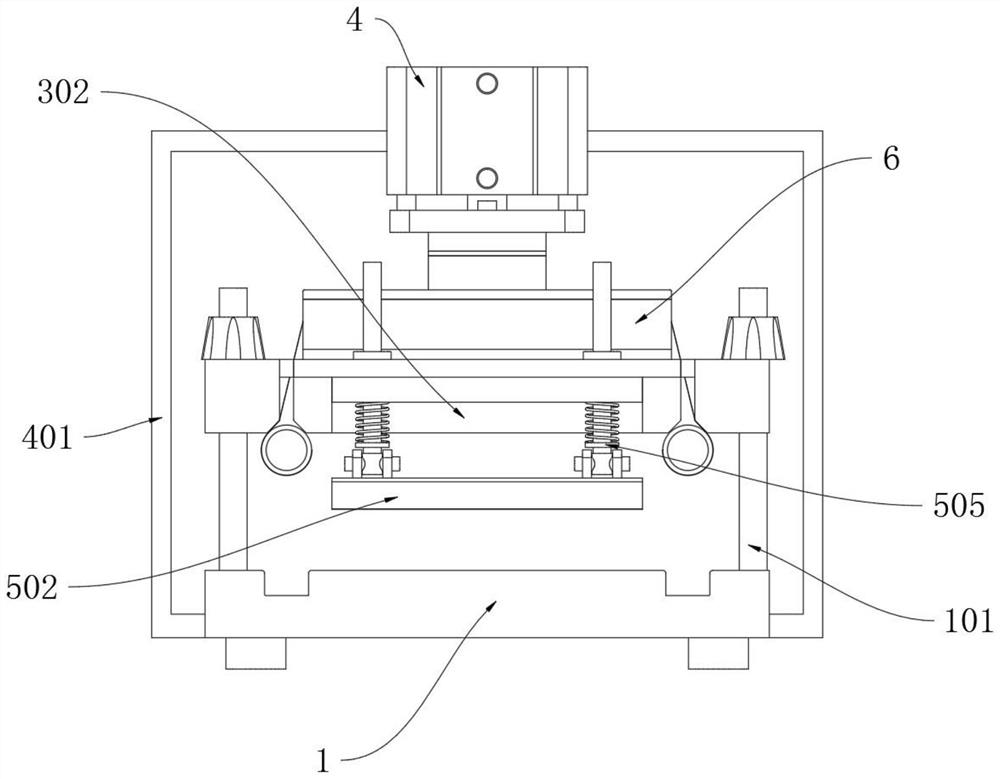

Hot pressing device for plate splicing for furniture production

ActiveCN111844280AImprove docking effectGuaranteed permeabilityPlywood pressesVeneer pressesHeat fluxEngineering

The invention provides a hot pressing device for plate splicing for furniture production, and relates to the technical field of furniture production equipment. The problems that in the plate splicingprocess, especially during hot pressing splicing, as the heat flux of splicing positions is small, the splicing heated range is wide, hot pressing splicing is hardly achieved accurately and rapidly, in addition, in the splicing process, two plates needing to be spliced need to be clamped through a clamp, in order to guarantee the tidiness of joints, the plates need to be aligned left and right andfront and back, and clamping is difficult are solved. The hot pressing device comprises a hot pressing table. End sealing mechanisms are slidingly mounted at the positions of the left end edge and the right end edge of the top plane of the hot pressing table upwards in a vertically-upward manner correspondingly. As rectangular air exchange grooves are formed in the middle of the bottom plane of the hot pressing table, due to the existence of guide blocks, air below can be prevented from entering upwards, and only hot air above can flow downwards.

Owner:山东凯迪威家具有限公司

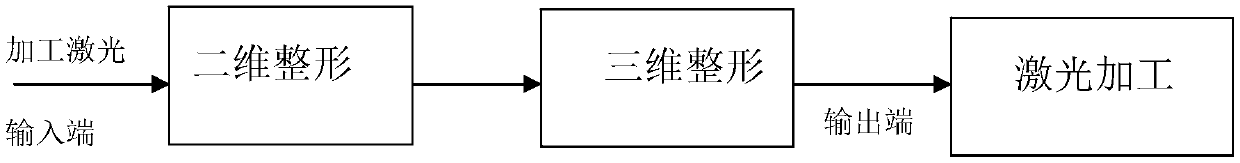

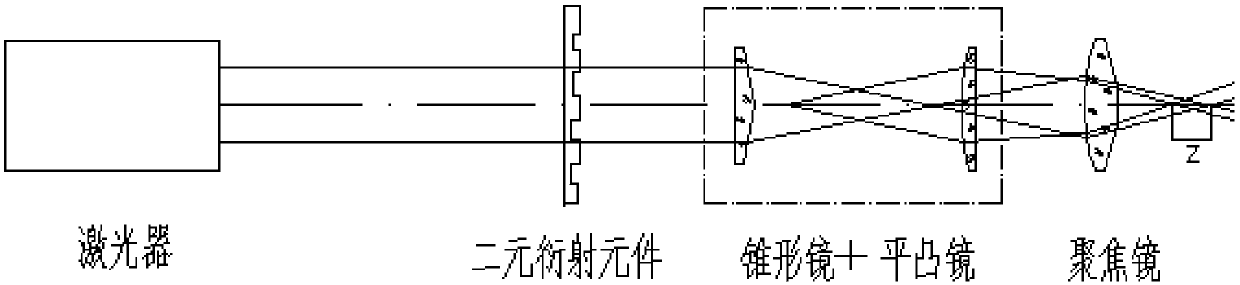

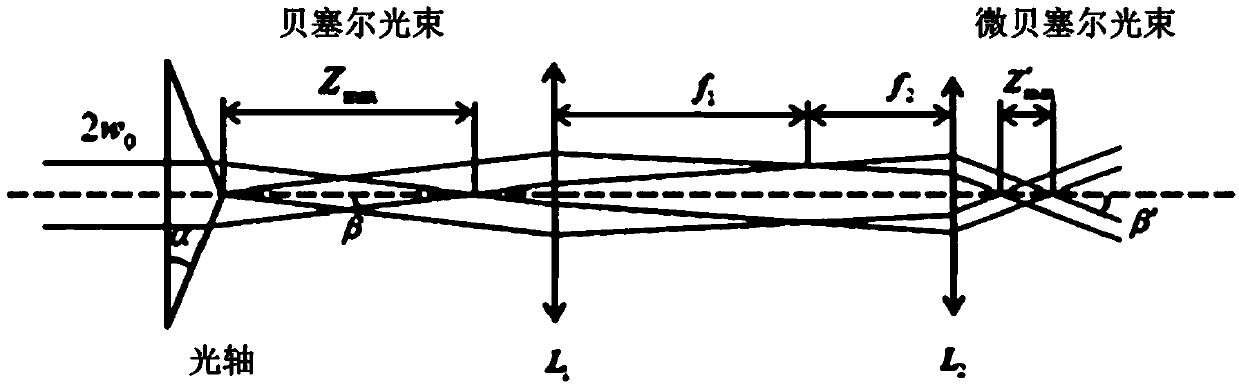

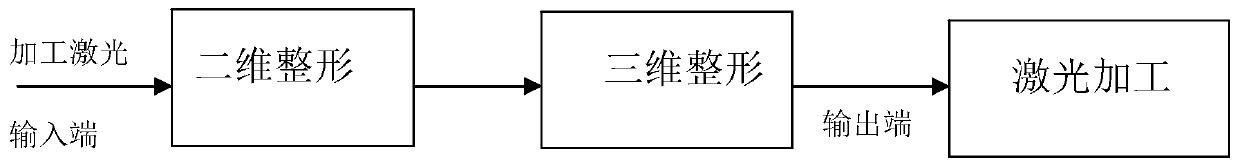

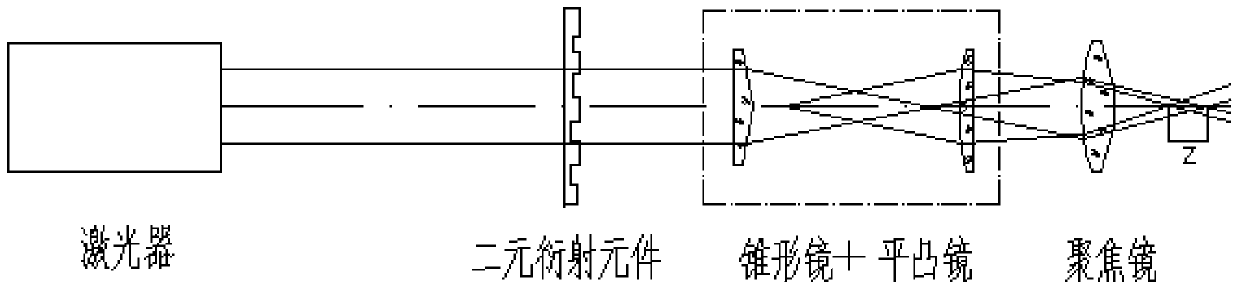

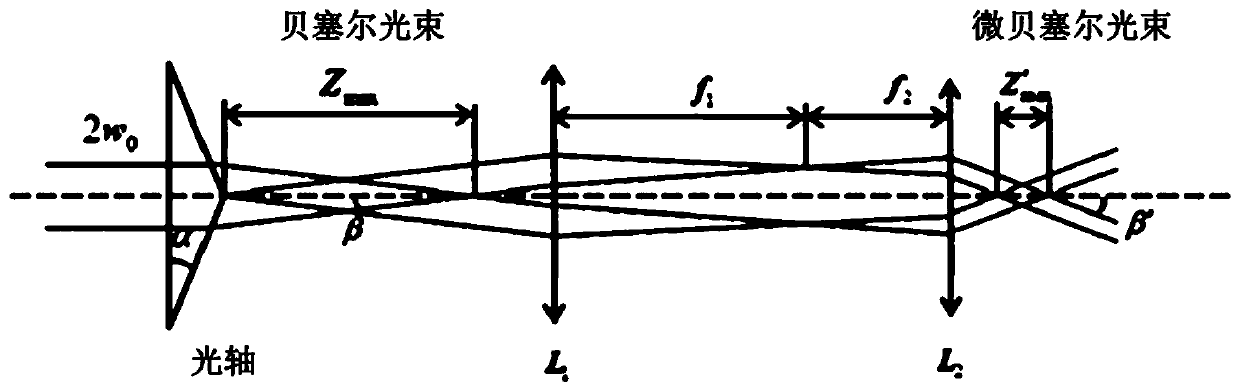

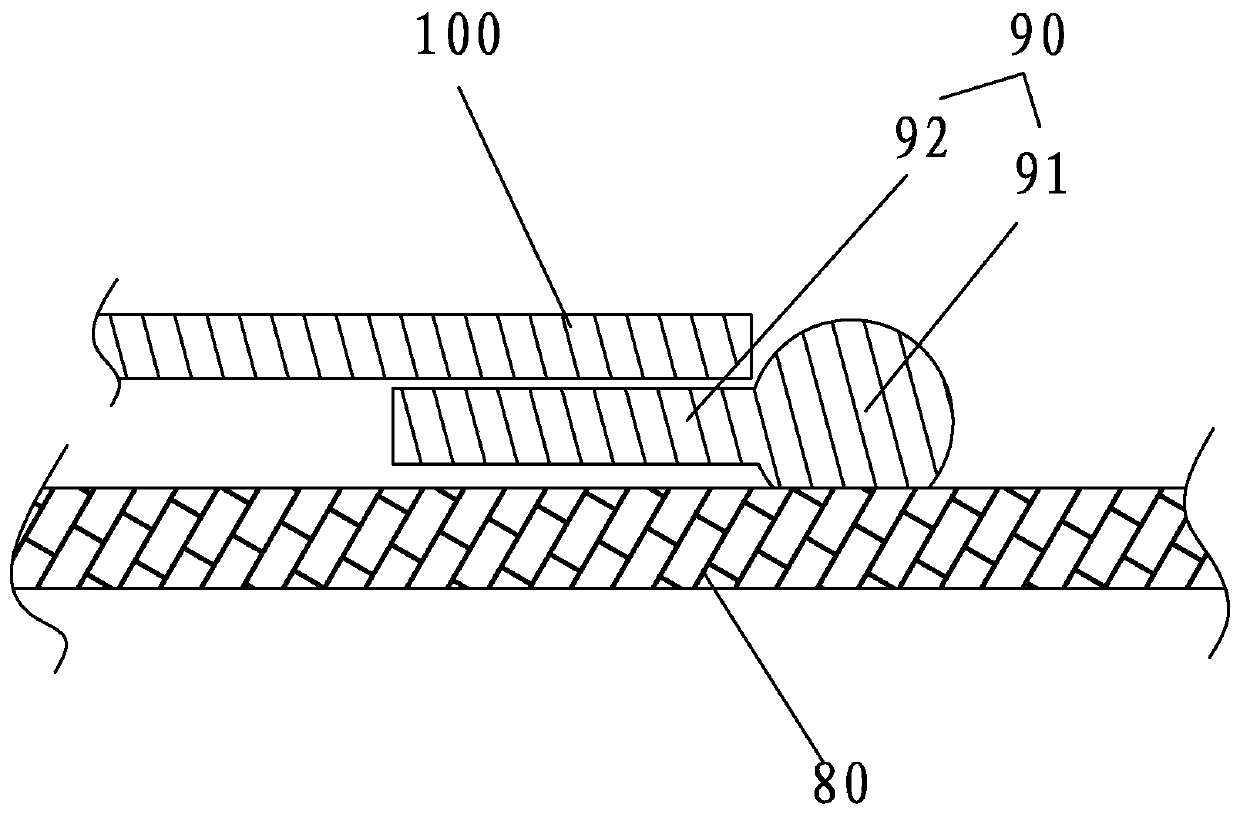

Non-taper laser machining method and machining device

ActiveCN109604837AReduce roughnessNeat seamsLaser beam welding apparatusLaser beam machiningOptoelectronics

The invention provides a non-taper laser machining method and machining device. According to the non-taper laser machining method and machining device, the problems of uncontrollable cutting slit taper, large slit roughness and low quality in an existing laser cutting mode, and laser non-taper cutting is realized. The non-taper laser machining method comprises the following steps that (1) two-dimensional shaping is carried out on a laser beam; a Gauss light spot of the laser beam is shaped into a rectangular uniform light spot of a two-dimensional plane; (2) three-dimensional shaping is carried out on the laser beam; the laser beam obtained in the step (1) is shaped into a long focal depth rectangular flat top laser beam; and (3) laser machining is carried out; the long focal depth rectangular flat top laser beam obtained in the step (2) is used for machining.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

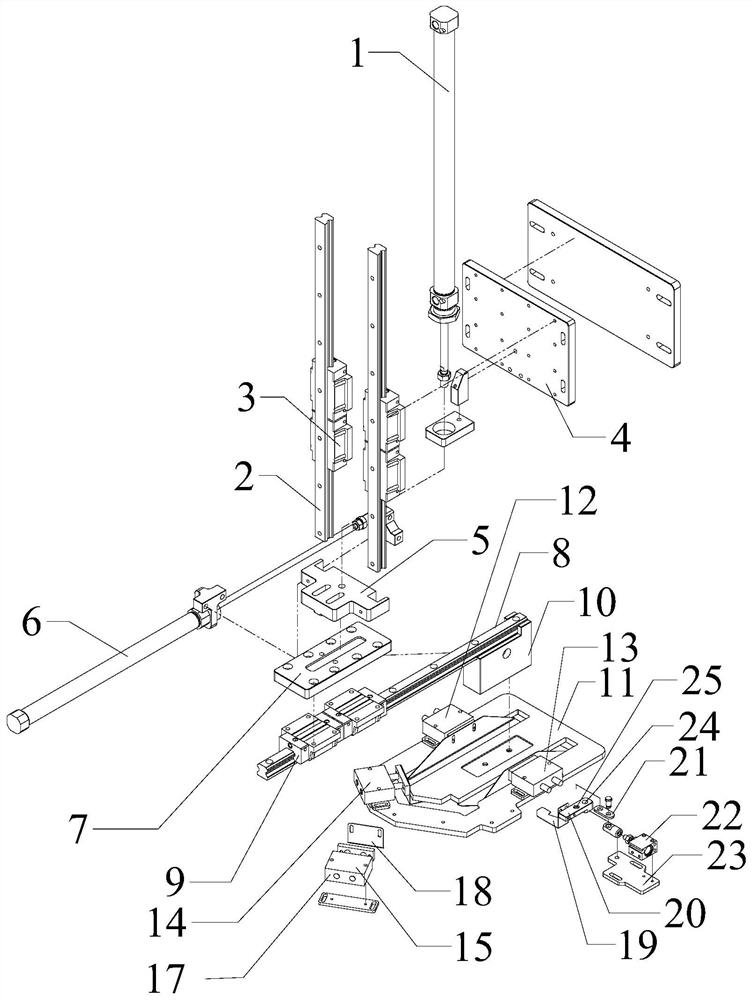

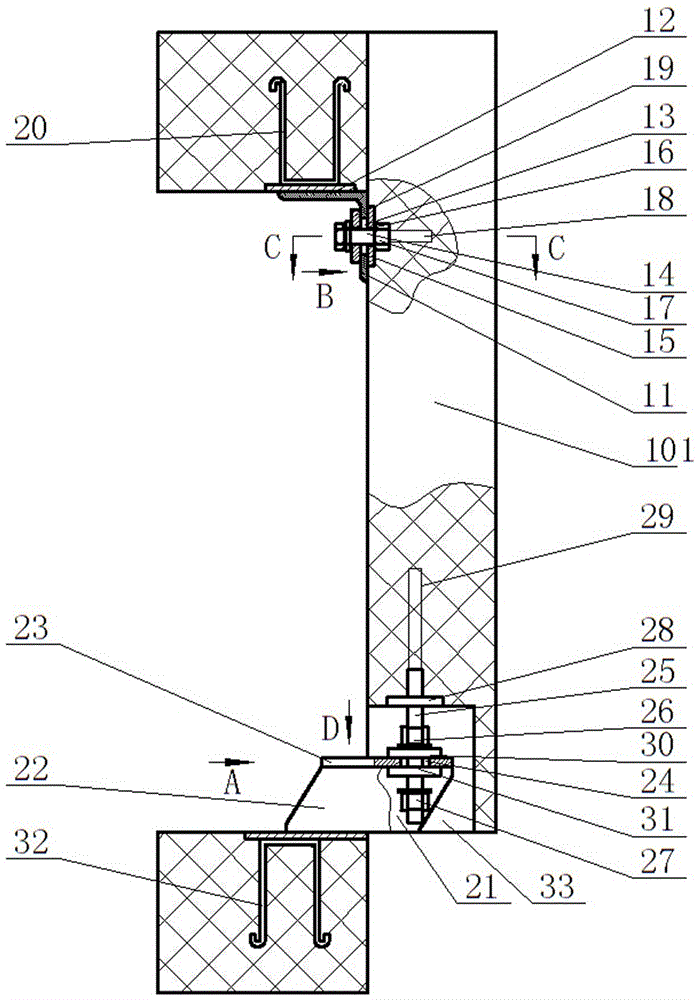

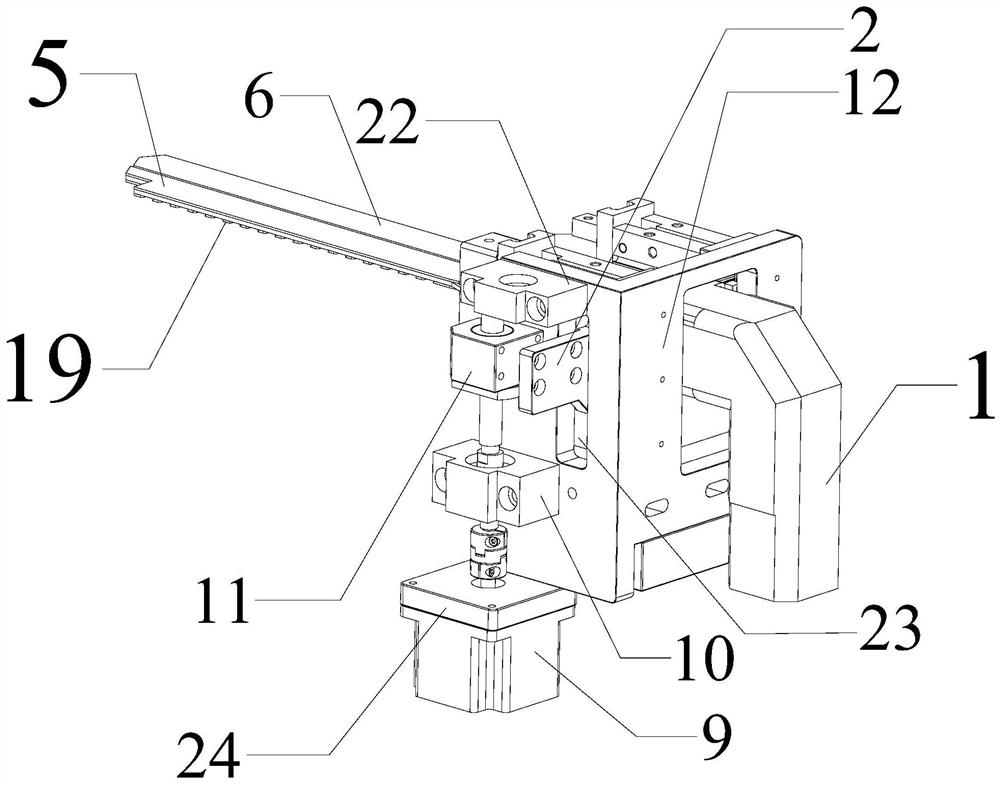

Cloth folding and setting mechanism of sleeve placket machine

The invention discloses a cloth folding and setting mechanism of a sleeve placket machine. An overturning motor is mounted on an overturning motor seat; the output end of the overturning motor penetrates through the overturning motor seat to be connected with a first clamping air cylinder; an upper clamping piece and a first lower clamping piece are mounted on the first clamping air cylinder; a positioning piece and a second lower clamping piece are mounted on a second clamping air cylinder; the first clamping air cylinder controls one end of the upper clamping piece to tilt up or press the first lower clamping piece; a lifting motor is mounted on a material folding adjusting seat; a lifting lead screw seat is mounted on the material folding adjusting seat; a lead screw is arranged in the lifting lead screw seat; the lead screw is connected with the output end of the lifting motor; a lifting connector is mounted on the lead screw; the lifting connector is fixedly connected with an overturning motor seat; the overturning motor penetrates through the material folding adjusting seat to be mounted on the overturning motor seat; and a positioning piece corresponds to a positioning template. The cloth folding and setting mechanism has the beneficial effects that the working efficiency of the sleeve placket machine is improved, and manpower and material resources can be saved.

Owner:东莞市宝韵自动化设备有限公司

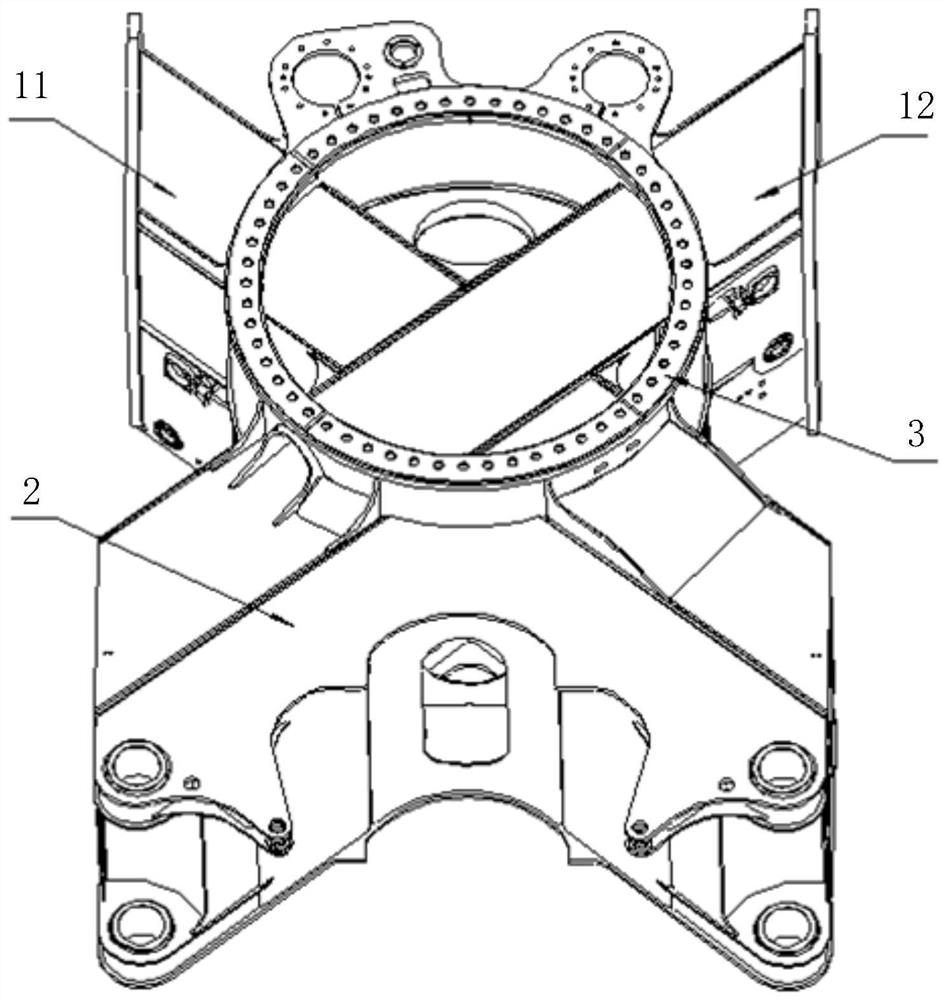

Concrete pump truck body frame and concrete pump truck

The invention relates to a concrete pump truck body frame and a concrete pump truck. The concrete pump truck body frame comprises a first supporting part, a second supporting part and a rotary supporting base. Before the body frame is formed, the rotary supporting base, the first supporting part and the second supporting part are independent components; the body frame is configured to be formed bywelding the first supporting part, the second supporting part and the rotary supporting base; and the first supporting part and the second supporting part are welded to form an X shape. The concretepump truck body frame is divided into the first supporting part, the second supporting part and the rotary supporting base, all sub-components are integrally tailor-welded after being tailor-welded, and each sub-component is relatively simple in structure, regular in weld joint and easy to independently perform automatic welding; the number of connecting weld joints between the sub-components is small, the connecting weld joints are all external weld joints, continuous and tidy, and parallel manufacturing can be achieved; and point splicing and pairing are conducted for overall automatic welding after construction is completed, so that automatic welding is easy, the welding production efficiency and the welding quality are improved, and the labor intensity is reduced.

Owner:XUZHOU XCMG CONSTR MACHINERY CO LTD BUILDING MACHINERY

Assembling method for double curved surface metal curtain wall

The invention discloses an installment method of hyperboloid metal curtain wall, which comprises that first designs the spatial solid shape of the metal curtain wall, divides the shape into curvatureblocks along longitude and woof, designs relative plane blocks based on the curvature blocks, feeds materials on the plane blocks, punches the plane blocks into relative curvature blocks, at last installs the curvatures into designed shape. The invention designs the size of plane block based on the curvature blocks via the equilateral distance method, to assure the engagement between the curvatures to obtain the high-quality joint between curvatures.

Owner:ZHEJIANG YASHA CURTAIN WALL

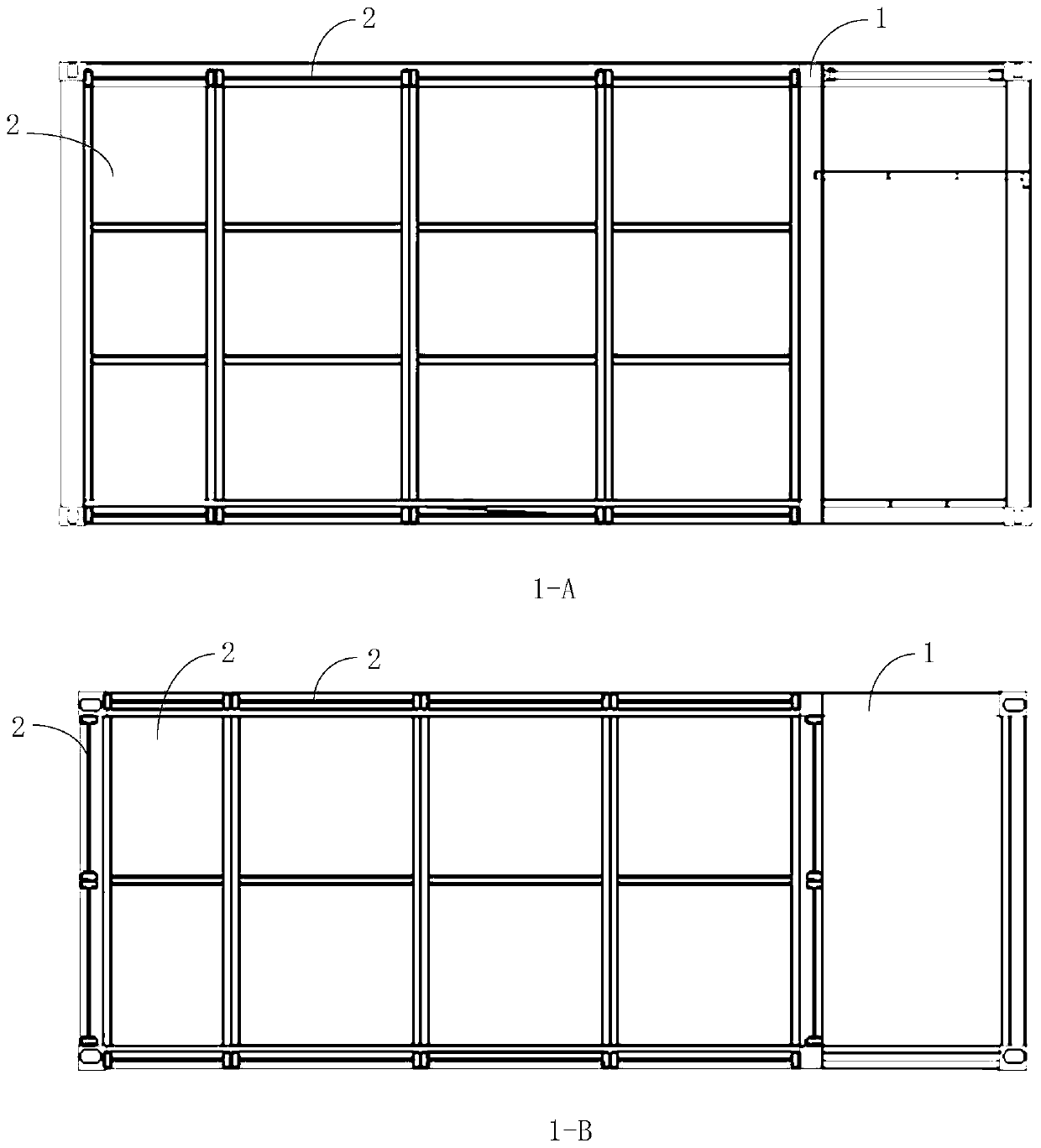

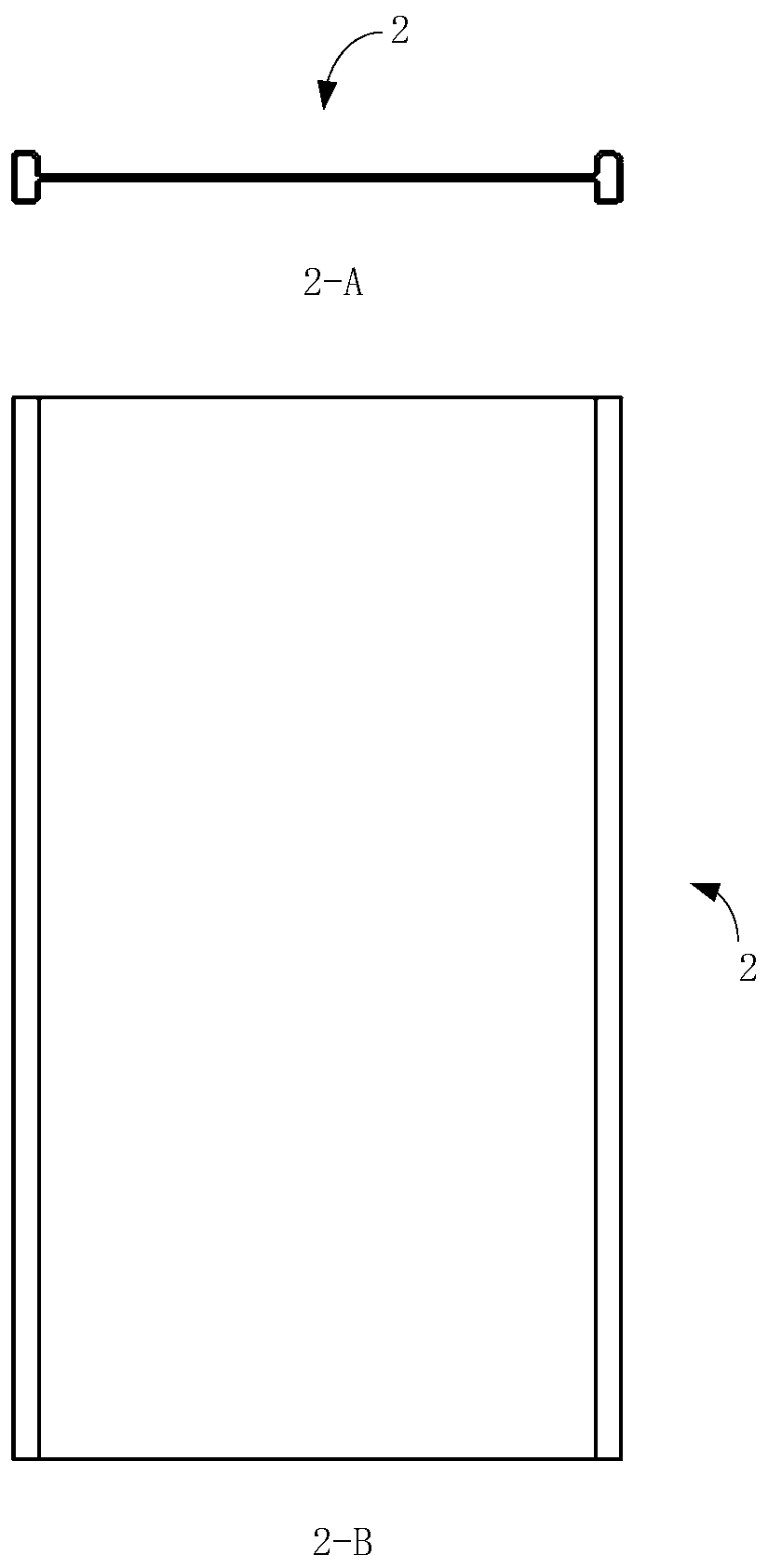

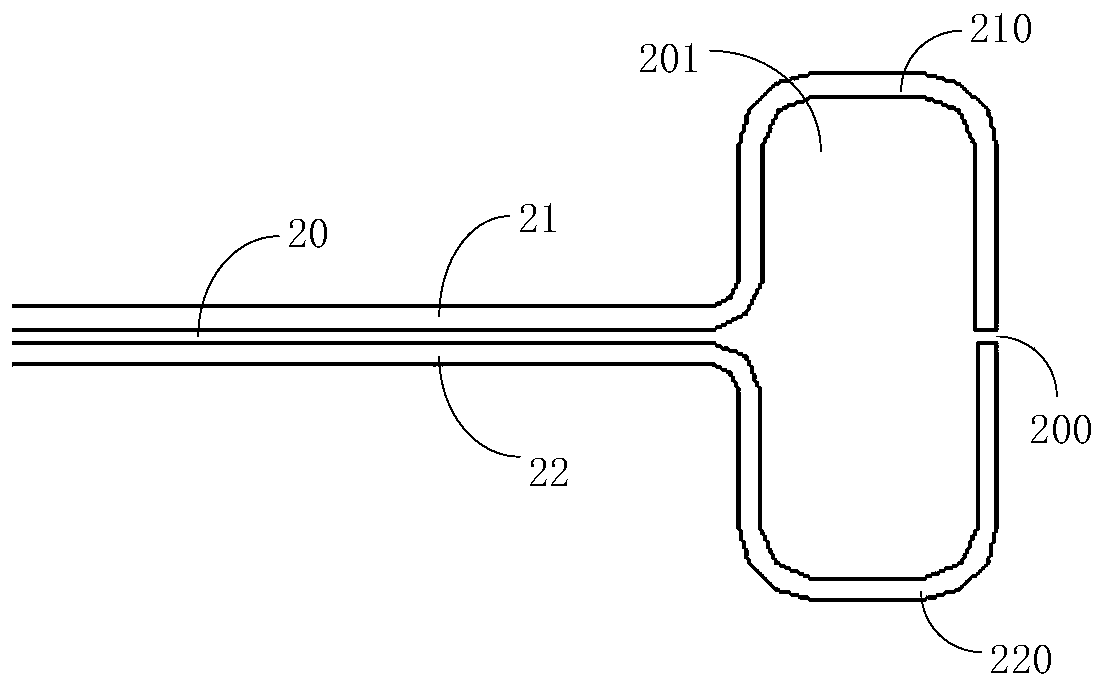

Skid-mounted refueling device

PendingCN111573612ASimple manufacturing processAchieve the effect of standard parts productionLiquid transferring devicesStructural engineeringAssembly line

The invention discloses a skid-mounted refueling device which comprises a rectangular frame and modular double-layer plate bodies. The rectangular frame is formed by assembling and welding square pipes and channel steel; the modular double-layer plate bodies are assembled and welded onto the rectangular frame so as to form an inner tank and an outer tank of the skid-mounted refueling device; eachdouble-layer plate body comprises an inner-layer plate body and an outer-layer plate body which are fixed through a welding manner; and a gap is left between each inner-layer plate body and the corresponding outer-layer plate body. With the modular structure design, an existing inner tank and an existing outer tank not only can be combined together but also can be divided into independent components and parts similar to door panels, and the dimensions can be unified to the greatest extent, so that a production and manufacturing process is simplified, a standard parts production effect can be achieved, the assembly line work is favorably realized, and the production efficiency is improved.

Owner:北京中储能能源设备有限公司

A non-taper laser processing method

The invention provides a non-taper laser machining method and machining device. According to the non-taper laser machining method and machining device, the problems of uncontrollable cutting slit taper, large slit roughness and low quality in an existing laser cutting mode, and laser non-taper cutting is realized. The non-taper laser machining method comprises the following steps that (1) two-dimensional shaping is carried out on a laser beam; a Gauss light spot of the laser beam is shaped into a rectangular uniform light spot of a two-dimensional plane; (2) three-dimensional shaping is carried out on the laser beam; the laser beam obtained in the step (1) is shaped into a long focal depth rectangular flat top laser beam; and (3) laser machining is carried out; the long focal depth rectangular flat top laser beam obtained in the step (2) is used for machining.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Manufacturing method of common box type ring network cabinet

The invention discloses a manufacturing method of a common tank type ring main unit. The manufacturing method of the common tank type ring main unit comprises the following steps: selecting materials, carrying out profiling, and grinding edges, which require to be welded, of a mounting plate, side plates and a sealing plate; forming an inflating hole, a gas-pressure meter hole and a plurality of binding post holes in the mounting plate; welding threaded posts for mounting a support on the inner side and the outer side of the mounting plate, and welding a threaded seat for fixing pull rods on the inner side of the mounting plate; manufacturing flange strips; connecting the side plates on two sides of the mounting plate; carrying out synchronous welding by laser and electric arc; embedding sealing rings in sealing grooves of the flange strips on the mounting plate and the sealing plate; connecting the pull rods; and sealing the sealing plate. By the manufacturing method of the scheme, the process of secondary welding can be reduced; and moreover, composite welding is adopted, a weld joint cannot crack easily.

Owner:贵州长征输配电电气有限公司

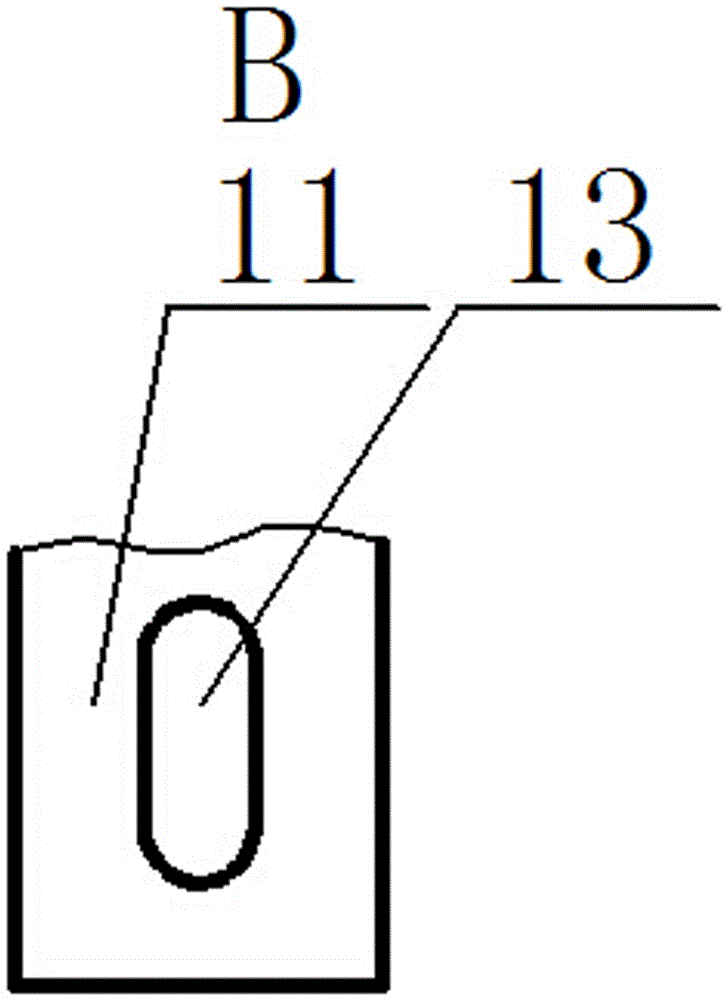

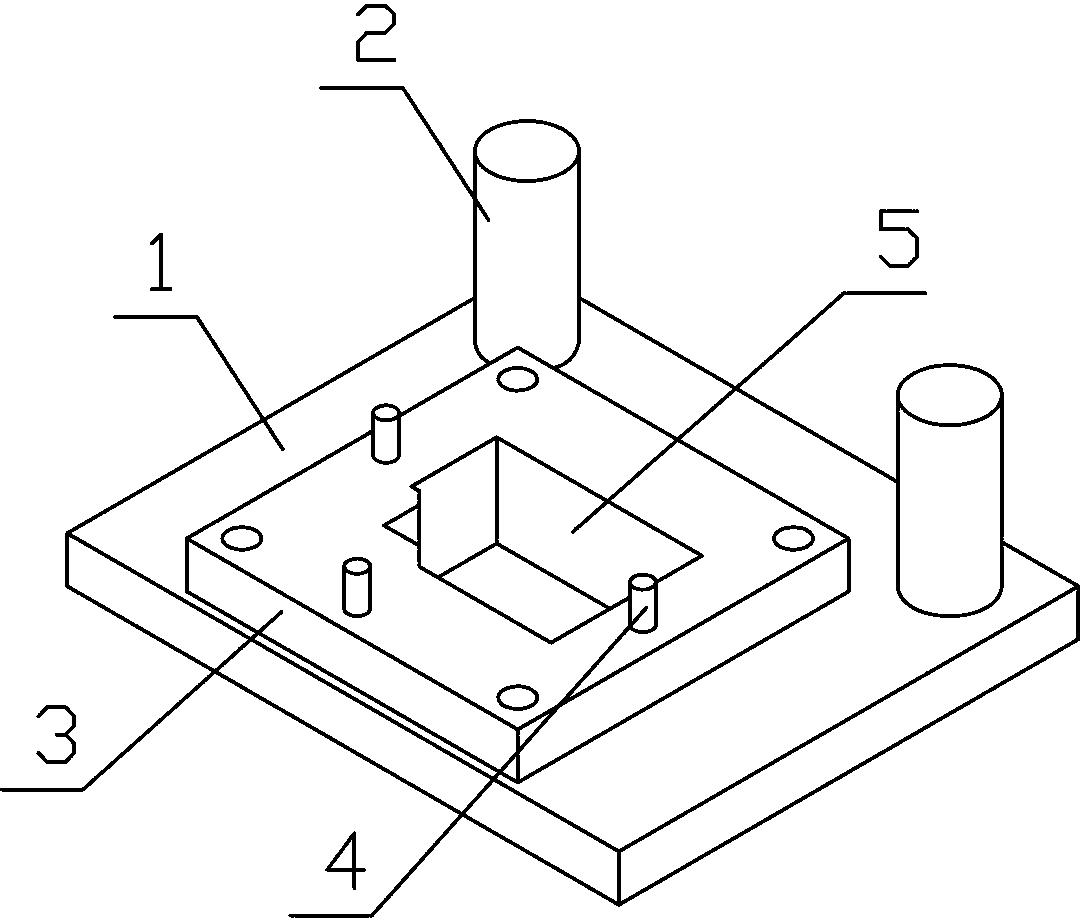

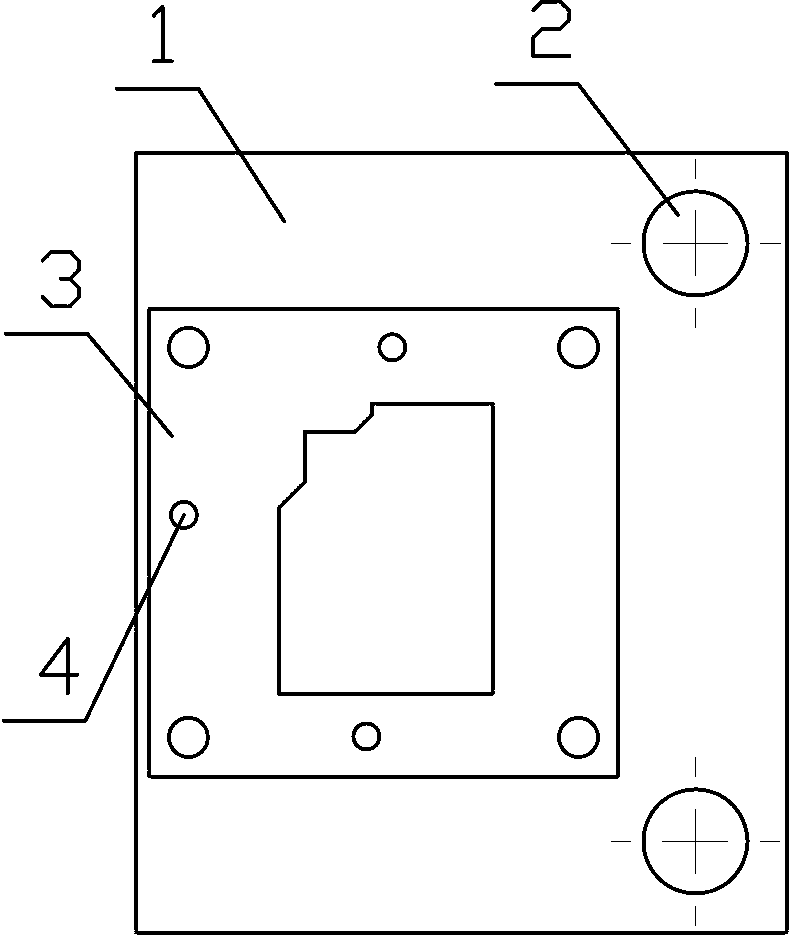

Corner punching die of door plate of mailbox

The invention relates to the field of mailbox production, in particular to a corner punching die of a door plate of a mailbox. The corner punching die comprises a concave die and a convex die, and ischaracterized in that the concave die comprises a base; two locating columns are arranged on the upper edge of the base; a die seat is mounted on the base through bolts and is provided with three locating pins; a die hole is formed in the middle of the die seat and is generally rectangular, and an inclined segment A, a straight segment A, a straight segment B, an inclined segment B and a straightsegment C which are connected in sequence are arranged at one corner; the convex die comprises a base, a die core is mounted on the base, the shape of the die core is completely the same as that of the die hole, and the outer portion of the die core is sleeved with a sleeve plate; three locating pin holes are formed in the sleeve plate, and the positions of the pin holes are in one-to-one correspondence to those of the locating pins; the sleeve plate is connected with the die core through elastic pads; and locating column sleeves are further arranged on the base and are matched with the locating columns. The corner punching die is suitable for mailbox production equipment.

Owner:湖北易宝通智能科技有限公司

Decorative strip guiding mechanism and stitching machine adopting same

PendingCN110042573ASimple structureImprove sewing efficiencyWork-feeding meansEngineeringMechanical engineering

The invention relates to a decorative strip guiding mechanism which comprises an installing part installed on a stitching machine body and a guiding block for guiding a decorative strip, a guiding groove is formed in the guiding block, the guiding mechanism further comprises a first regulating block and a second regulating block, a regulating part is arranged on the guiding block, the regulating part can be installed on the first regulating block in the mode that the adjusting part can be transversely moved and adjusted along the first regulating block through a first regulating mechanism, thefirst regulating block is installed on the second regulating block in the mode that the first regulating block is moved and regulated longitudinally through a second regulating mechanism, and the second regulating block is installed on the installing part. The decorative strip is guided by the guiding groove to walk, when the decorative strip, the decorative block and a vamp are sewn together, accurate alignment can be achieved, it is ensured that stitches are neat, and the sewing efficiency and sewing quality are improved, the invention further provides a stitching machine adopting the decorative strip guiding mechanism, and the sewing efficiency and the sewing quality of the decorative strip can be effectively improved.

Owner:XTEPCHINA

A hot pressing device for panel splicing in furniture production

ActiveCN111844280BImprove docking effectGuaranteed permeabilityPlywood pressesVeneer pressesHeat fluxMechanical engineering

The invention provides a hot-pressing device for panel splicing used in furniture production, which relates to the technical field of furniture production equipment, to solve the problem of splicing problems due to the small heat flux at the splicing position during the splicing process of panels, especially during hot-press splicing. The heating range is wide, and it is difficult to accurately and quickly realize hot-press splicing. In addition, during the splicing process, fixtures are required to clamp the two panels to be spliced. The more difficult problem includes the hot pressing table; the left end edge and the right end edge of the top plane of the hot pressing table are respectively vertically slid upwards and installed with end sealing mechanisms. In the present invention, since the middle part of the bottom plane of the hot pressing table is provided with a rectangular ventilation slot, and due to the existence of the deflector block, the air below can be prevented from entering upwards, and only the hot air above can flow downward.

Owner:山东凯迪威家具有限公司

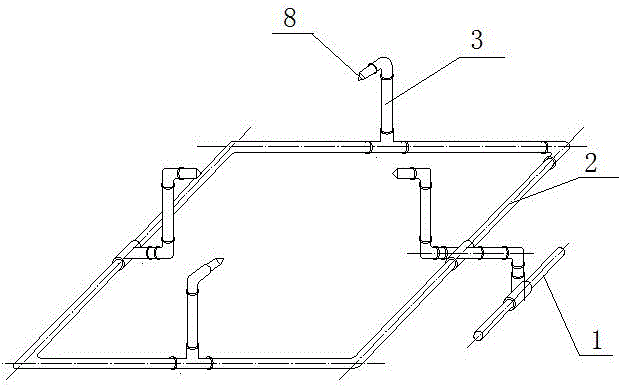

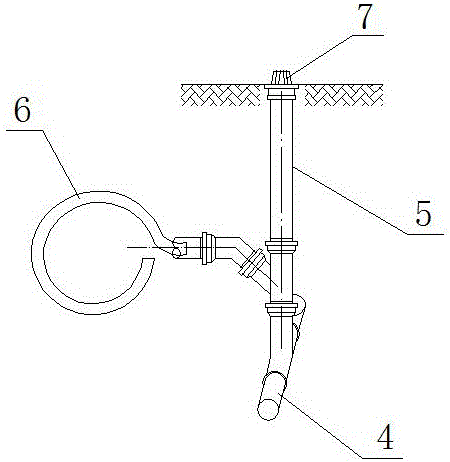

Combined assembling type construction method of steel tree pond

InactiveCN106034788AAchieve self-regulationImprove carrying capacityPaving gutters/kerbsReceptacle cultivationSewageEngineering

The invention provides a combined assembling type construction method of a steel tree pond, and relates to the technical field of planting of trees. When the trees are planted, an irrigation pipeline and a drainage pipeline are both buried in the ground. According to the drying degree of weather, the irrigation pipeline is used, and a vertical water supply pipe arranged on the periphery of each tree is used for regularly watering the tree in an invisible manner. When accumulated water on an earth surface is too much due to continuous rainfall, a vertical pavement drain pipe can be used for collecting the accumulated water on the earth surface and drain the collected accumulated water through a sewage drainage pipe; and redundant moisture in soil at the roots of the trees can be filtered through a penetrating pipe wrapped by a filter cloth and then drained through the sewage drainage pipe. Therefore, the planting method disclosed by the invention achieves the effect of self adjusting of the moisture in the soil in root systems of the trees.

Owner:江苏扬州建工建设集团有限公司

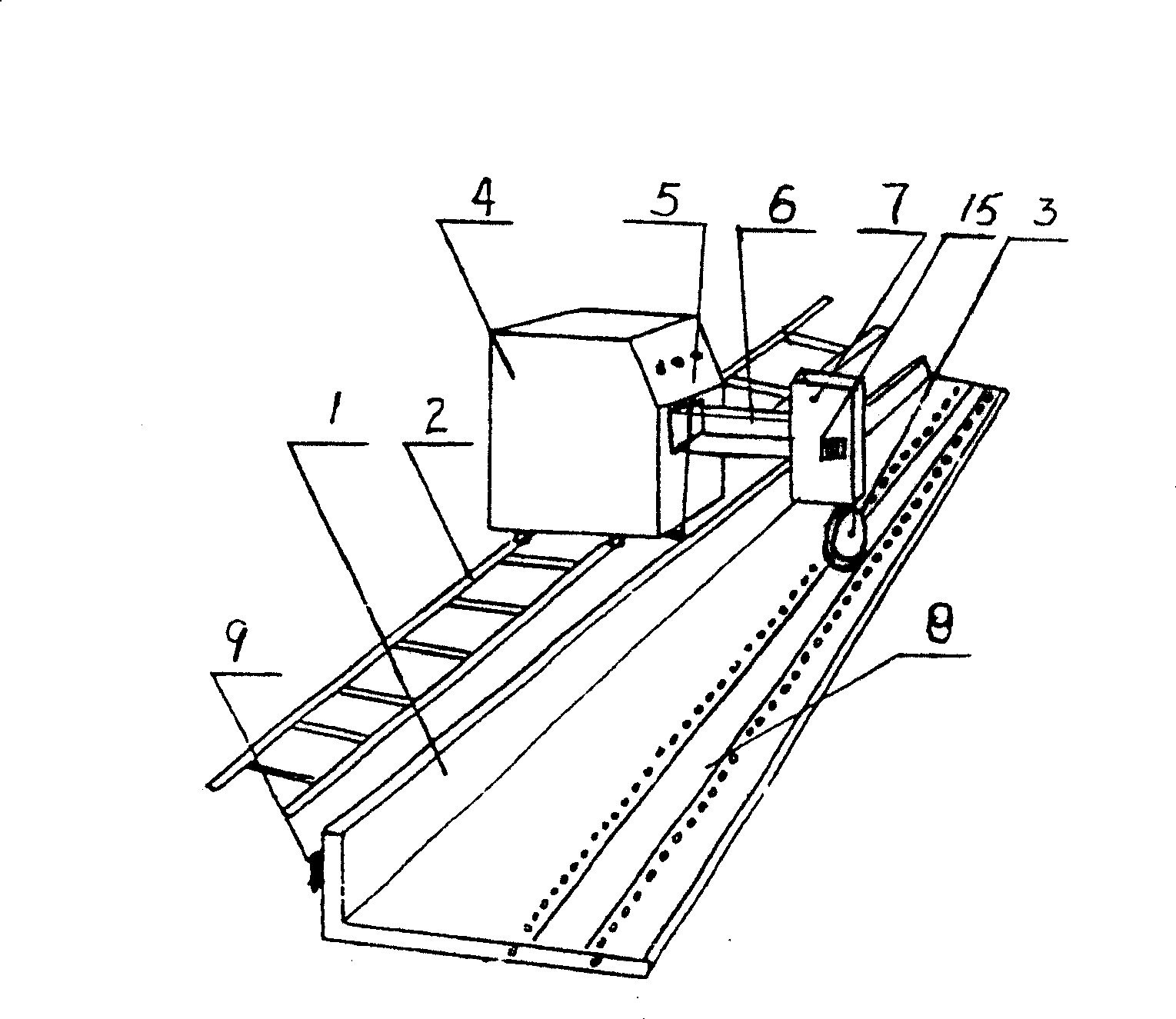

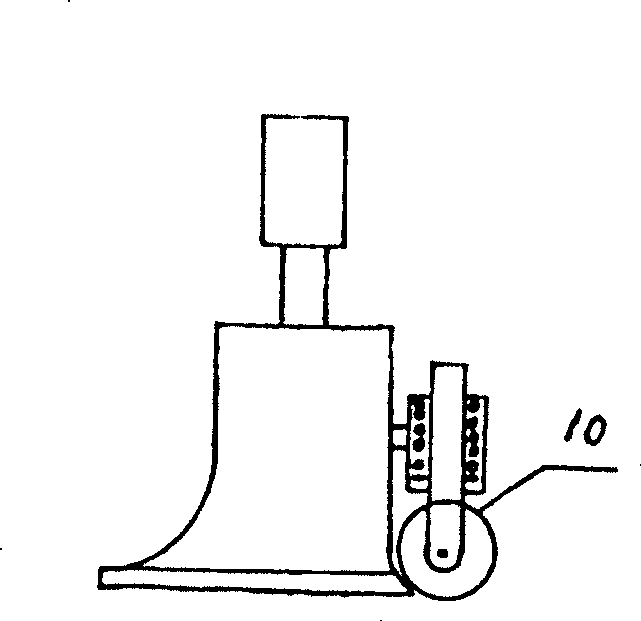

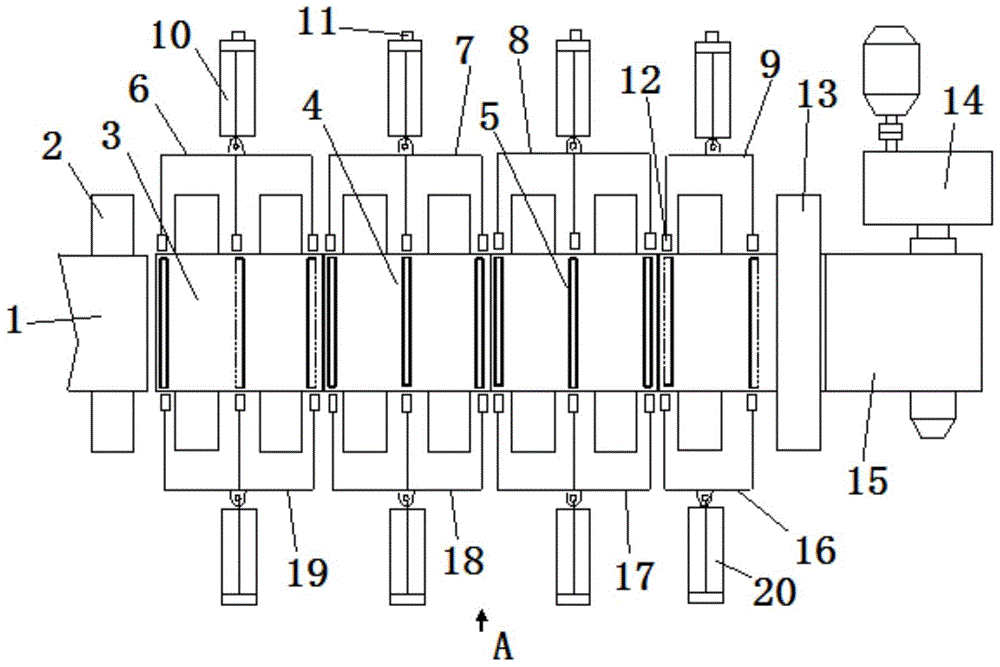

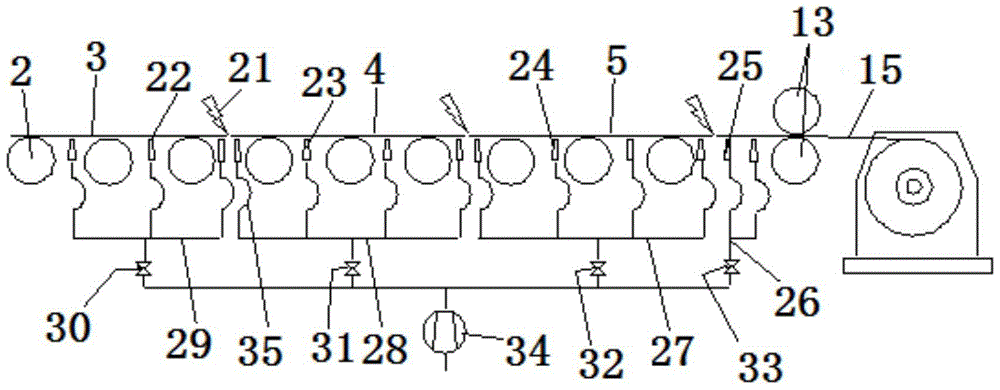

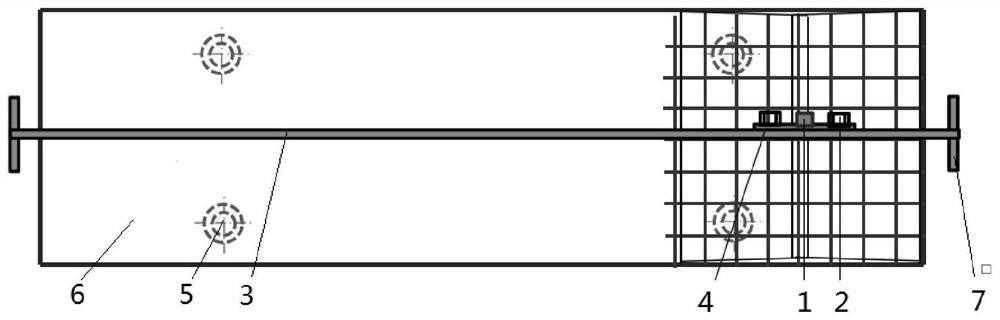

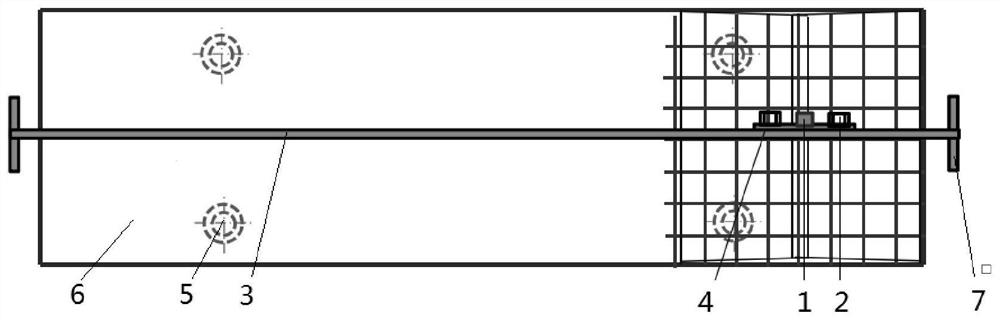

A thin steel plate continuous tailor welding device and tailor welding method

The invention discloses a thin-steel-plate continuous tailor-welding device and a tailor-welding method. The tailor-welding device comprises a conveying roller way, centering devices and vacuum locating devices, wherein the conveying roller way is used for conveying thin steel plates to be welded, the centering devices are arranged at the two sides of the conveying roller way, and the vacuum locating devices are arranged below the thin steel plates to be welded. The tailor-welding method comprises the step of realizing the welding of the thin steel plates by using the thin-steel-plate continuous tailor-welding device. According to the thin-steel-plate continuous tailor-welding device and the tailor-welding method, the welding process of the thin steel plates can be stable and cannot be subjected to deforming and warping, weld seams are orderly after welding is completed, the welding speed is increased, the quality of welding is good, and the smoothness of the welded steel plates is good.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Low hydrogen type iron powder welding rod and preparation method thereof

ActiveCN106425171BGood lookingWeld seam corrugation is goodWelding/cutting media/materialsSoldering mediaSlag (welding)Iron powder

The invention belongs to the technical field of welding materials, and particularly involves a low-hydrogen iron powder electrode and preparing method. The coating of low-hydrogen iron powder electrode is made up of following parts by weight: 47 to 49 parts of marble, 13 to 15 parts of fluorite, 2 to 4 parts of ferrosilicon, 1.5 to 2.5 parts of titanium dioxide, 1.5 to 2.5 parts of wood powder, 14 to 16 parts of rutile, 4 to 6 parts of feldspar powder, 6 to 8 parts of silica flour, 4 to 6 parts of mica powder, 12 to 14 parts of titanium valve, and 19 to 21 parts of iron powder. The low-hydrogen iron powder electrode has the advantage of overall good appearance of weld seam, parallel sideline and knitting well with mother metal. Weld seam is neat for ripple, and the height of weld seam is close to. The surface of weld seam does not have the disadvantage of pore-free, crackle, slag inclusion, undercut, and overlap. The welding slag after welding rod is easy to fall off.

Owner:PANZHIHUA UNIV

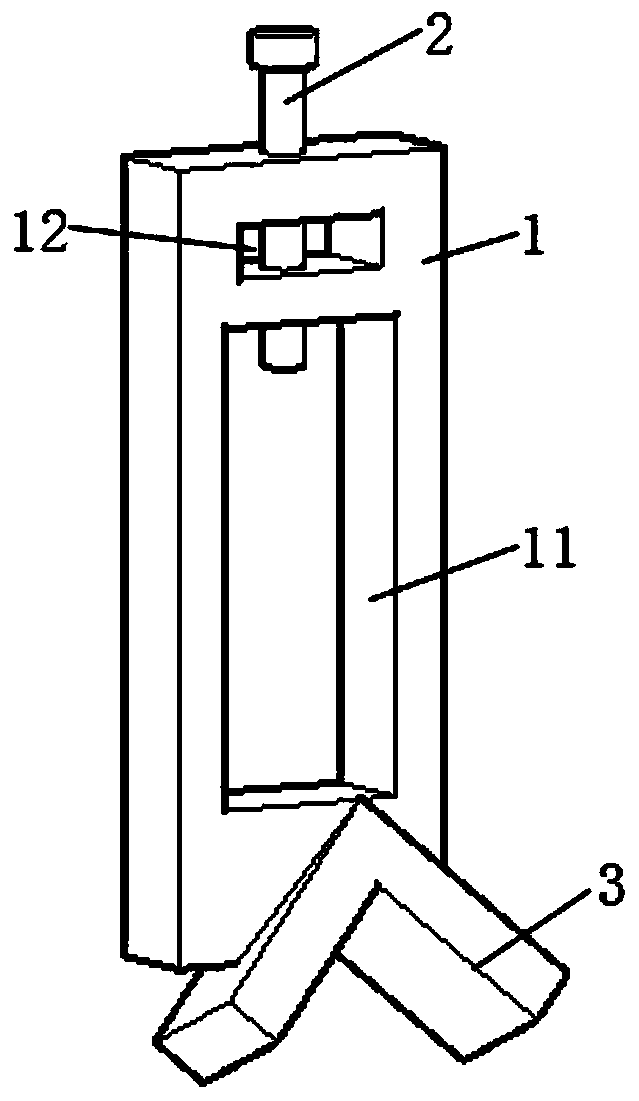

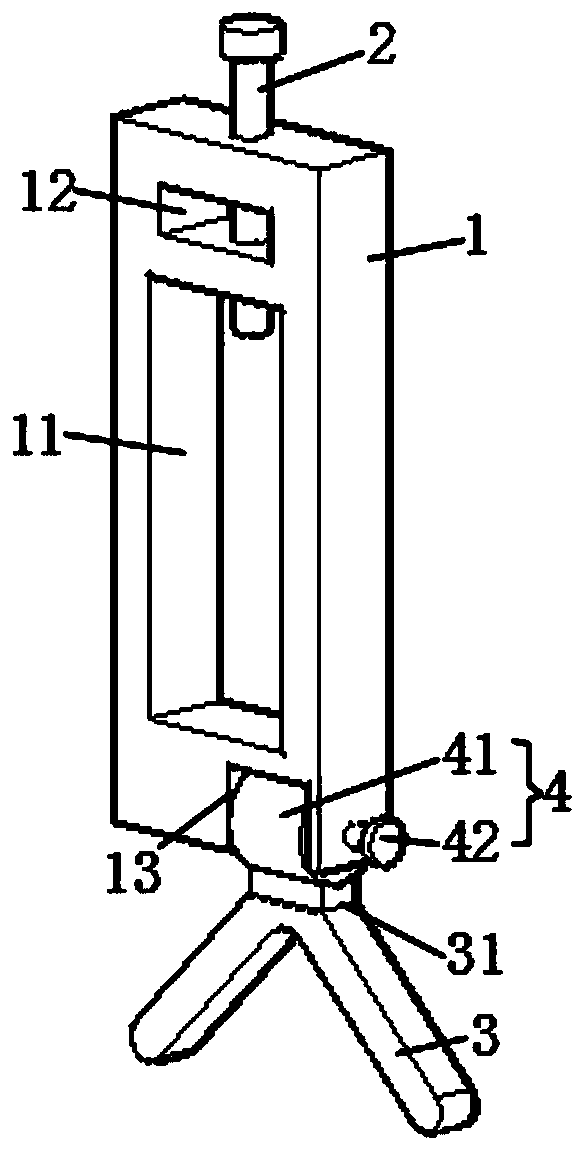

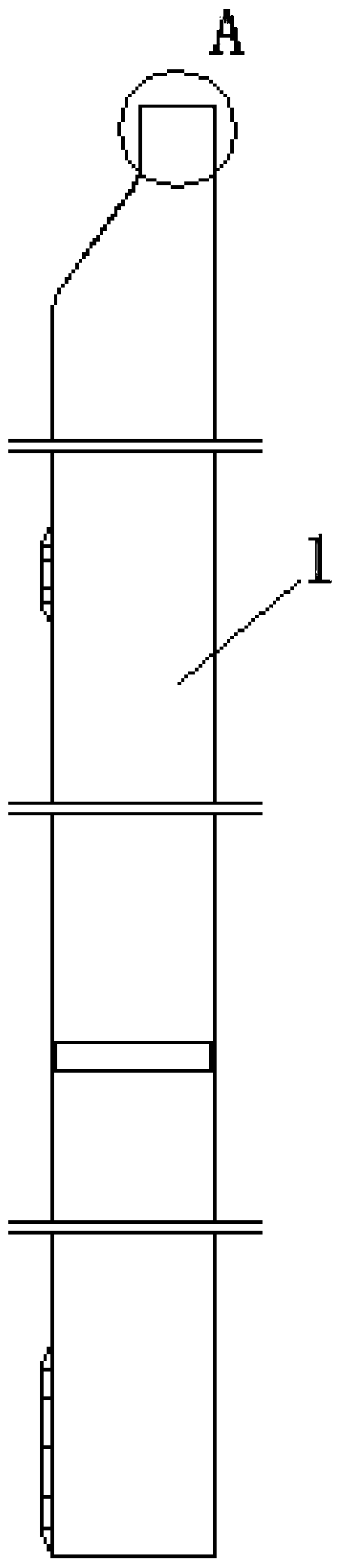

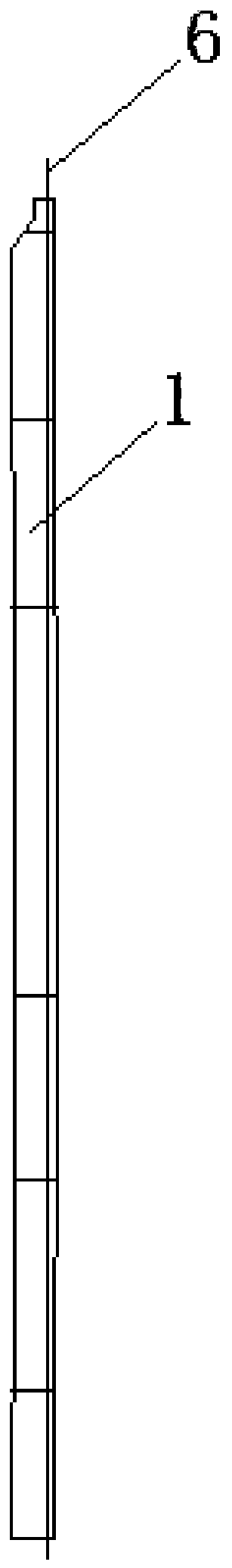

Anti-deviation device for cable cutting

PendingCN111293637AImprove the feelEasy cuttingApparatus for removing/armouring cablesApparatus for joining/termination cablesScrew threadElectric cables

The invention discloses an anti-deviation device for cable cutting. The anti-deviation device comprises an anti-deviation device body, a cutter locking bolt and a triangular clamp. The anti-deviationdevice body is fixed at the top of the triangular clamp; a cutter groove for mounting a cutter runs through the anti-deviation device body along the length direction of the cable; the opening of the clamping groove of the triangular clamp is arranged downwards, and the triangular clamp is vertically clamped at the top of a horizontally placed cable; the cutter locking bolt penetrates through a threaded hole in the anti-deviation device body and is matched with the threaded hole in the anti-deviation device body; and the extrusion end of the cutter locking bolt faces the cutter. The device is simple in structure, low in manufacturing cost and convenient to use.

Owner:HUAINAN MINING IND GRP

Main girder of a crane and processing method thereof

ActiveCN105540429BImprove rigidityAvoid deflectionLoad-engaging girdersWelding apparatusEngineeringMachining

The invention discloses a crane main beam. The crane main beam comprises a first web, a second web, reinforced frames, a top plate and a bottom plate. The top plate is connected with the top of the first web, and the bottom plate is connected with the bottom of the second web. The reinforced frames are arranged in the main beam at intervals and are fixedly connected with the first web, the second web, the top plate and the bottom plate respectively. The first web and the second web are each provided with a camber. The first web and the second web are both formed in a sequence welding manner. Staggering distances are set between segmented weld joints of the first web and between segmented weld joints of the second web. Due to the fact that the first web and the second web of the main beam are formed in the sequence welding manner and a certain staggering distance is kept between every two adjacent segmented weld joints of the two webs, stress of the main beam is dispersed because of arrangement of the weld joints; due to a new machining technology, the rigidity of the main beam is enhanced, and flexibility caused when a long-span main beam generates bending moment because of dead weight is effectively prevented.

Owner:CHANGZHOU CHANGKUANG HOISTING MACHINERY

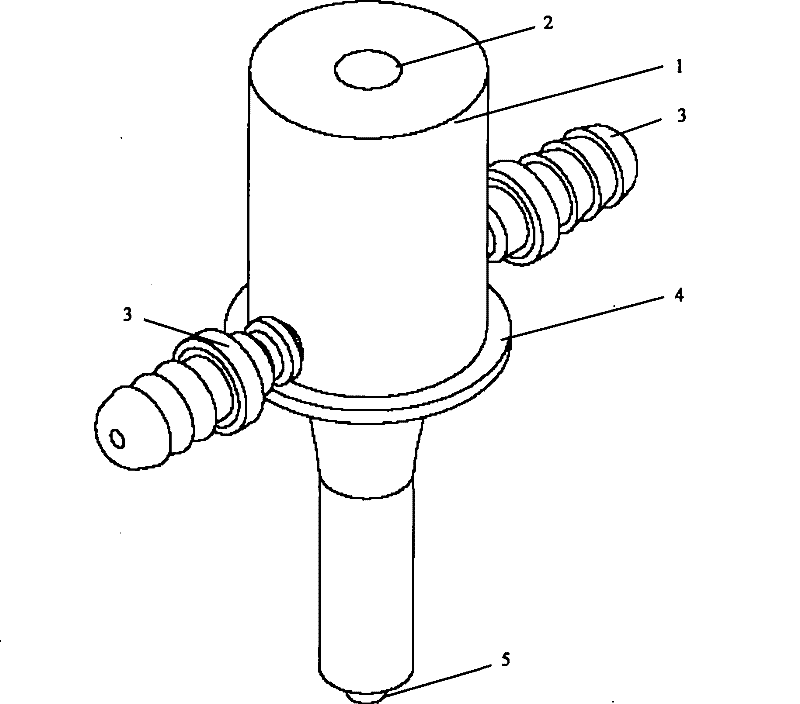

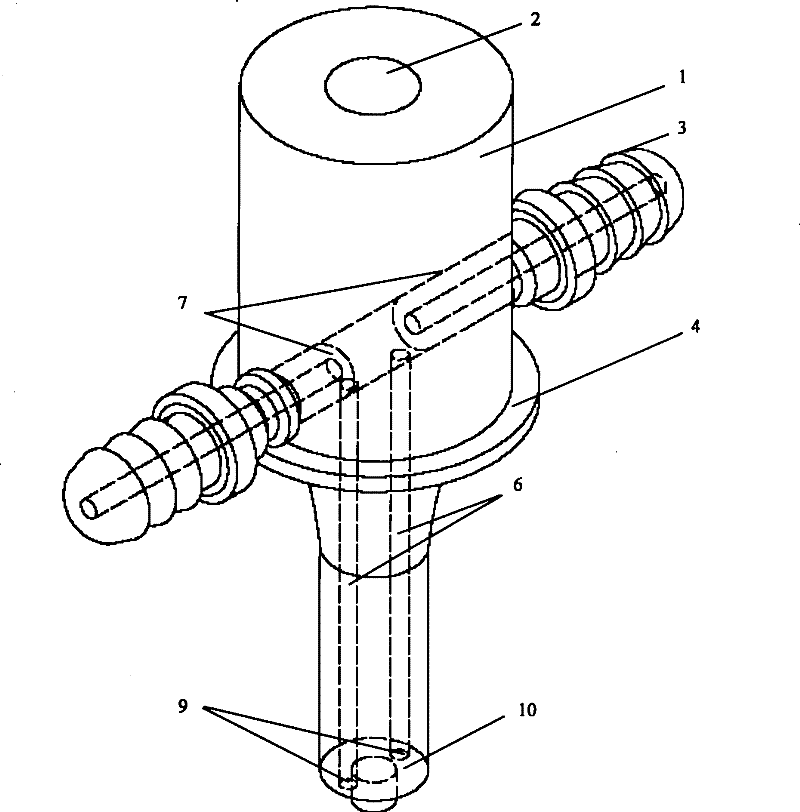

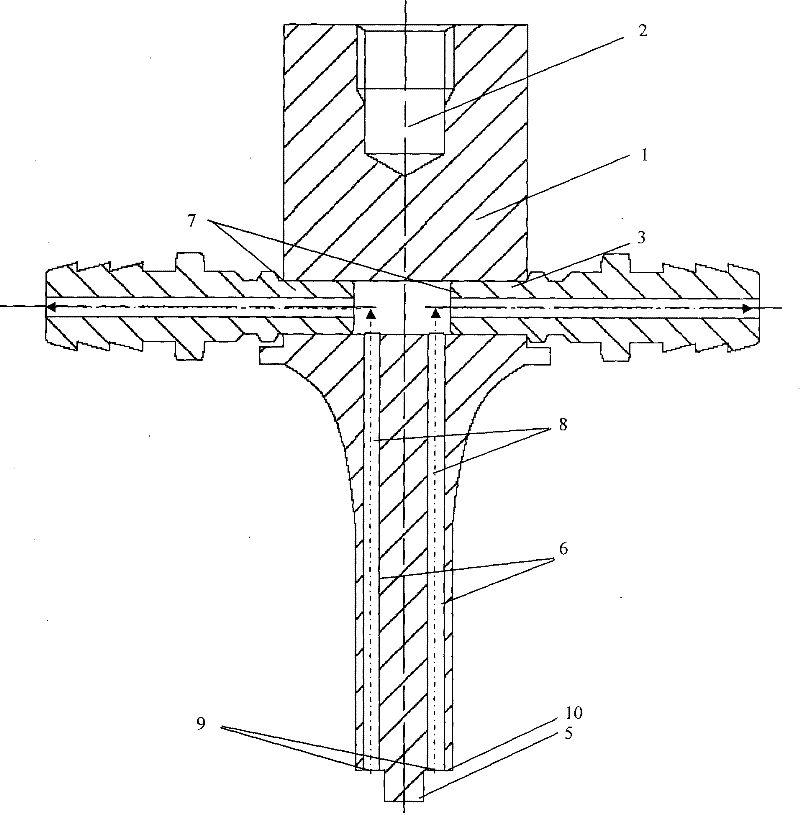

Adsorption-type ultrasonic tool head applied to the connection of polymer micro-devices

InactiveCN101396866BRealize the amplitude amplification function of vibrationUniform weldingProcess qualityStructural dynamics

An adsorption-type ultrasonic welding tool head applied to the connection of polymer micro-devices belongs to the technical field of assembly of polymer micro-devices. The fixed structure of the weldment and the vacuum adsorption clamping structure are provided with a ventilation interface at the node position of the tool head. The effects and benefits of the present invention are that after structural dynamics analysis, the structural design realizes the amplitude amplification function of the vibration of the ultrasonic transducer, and the radiation surface vibrates evenly, which ensures uniform welding of devices and neat weld seams, and can significantly improve the ultrasonic welding efficiency. Processing quality. The ventilation interface is located at the node position of the tool head, which can avoid the influence of ultrasonic high-frequency vibration on it. The ultrasonic tool head involved in the present invention has a clamping and fixing structure for the device to be connected, and is an automatic assembly of polymer micro-functional devices. Foundation.

Owner:DALIAN UNIV OF TECH

Floor rubber pad thickness analysis method and system suitable for metro vehicles

PendingCN113959347AGuaranteed reliabilityGuaranteed accuracyImage enhancementImage analysisAutomotive engineeringMesh grid

Owner:NANJING ZHONGCHE PUZHEN URBAN RAIL VEHICLE CO LTD

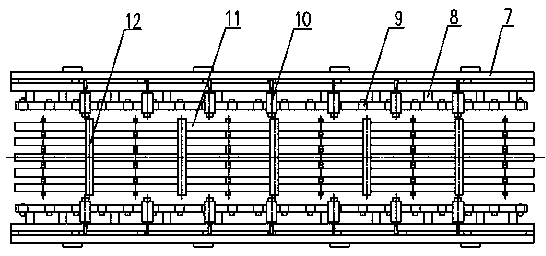

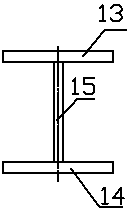

H-shaped steel welding device and welding process thereof

InactiveCN102343493BHigh degree of welding automationUniform weldingWelding/cutting auxillary devicesAuxillary welding devicesLaser scanningEngineering

The invention discloses an H-shaped steel welding device and a welding process thereof. The adopted technical scheme is as follows: the H-shaped steel welding device comprises an input part, a welding part and an output part and is characterized in that the welding part comprises a flange slab clamping and positioning device, a web plate conveying device and at least one mechanical arm, wherein the mechanical arm is mounted on a welding station and can move under the drive of the welding station, the mechanical arm is further connected with a mechanical head, and the mechanical head can be replaced by any of a laser scanning head, a welding head or a cutting head. The H-shaped steel welding device has the beneficial effects that the H-shaped steel welding device is high in degree of welding automation, uniform and neat in weld joints, and high in strength, the whole process is completed automatically under the control of a program, laser scanning, welding and cutting processing can be sequentially completed by adopting the mechanical arm, the working efficiency is greatly improved and the cost can be saved by above 20%.

Owner:山东金瑞诺华兴机械有限公司

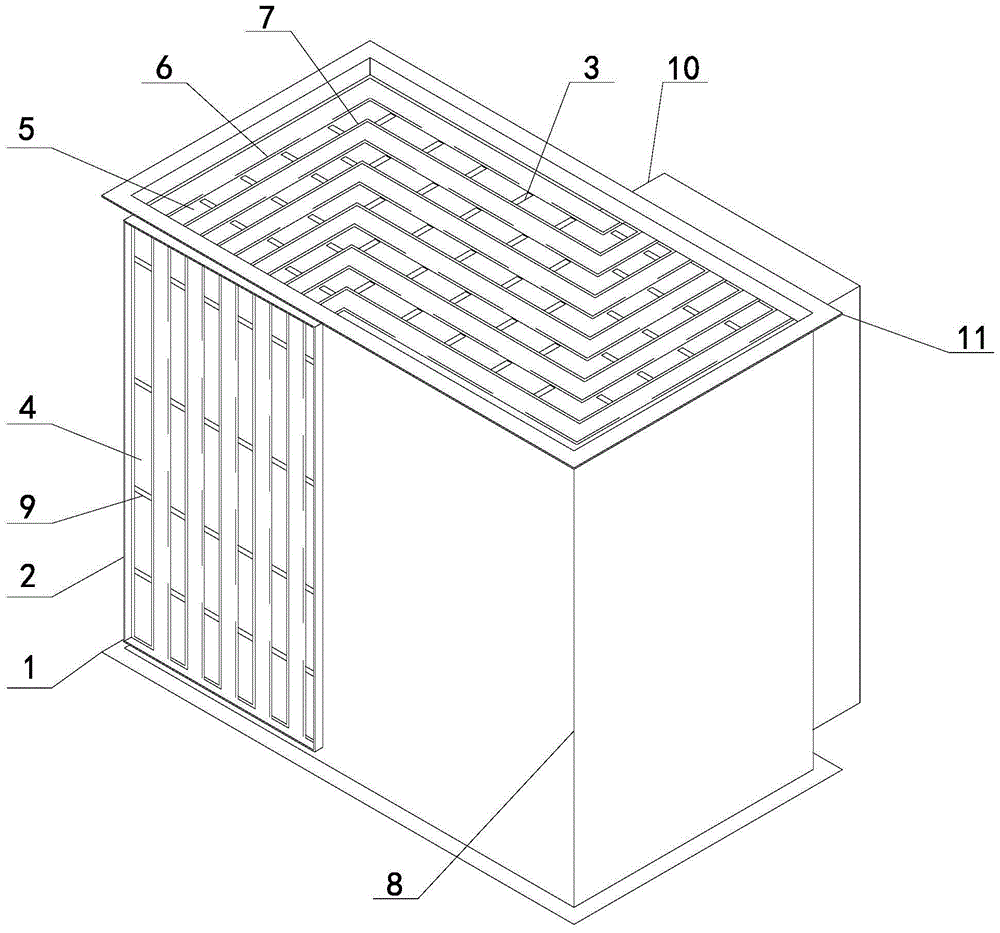

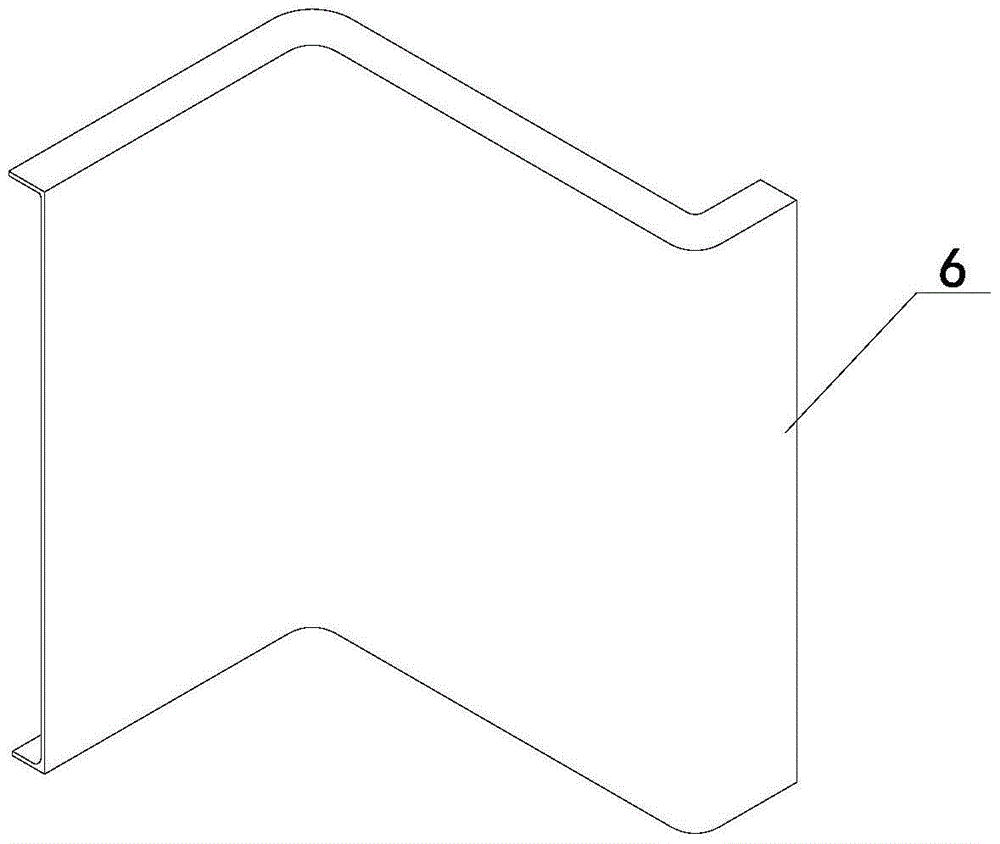

A New High Efficiency Welded Plate Heat Exchanger

ActiveCN105135918BIncrease the circulation areaImprove flow uniformityLaminated elementsStationary plate conduit assembliesHeat transfer efficiencyEngineering

Owner:LUOYANG MINGYUAN PETROCHEM IND TECH +1

Reverse balance flange connecting joint and manufacturing method and application thereof

ActiveCN110671279AImprove fatigue resistance levelReduce weldingFinal product manufactureWind motor assemblyAdhesiveTower

The invention relates to a steel tower double-ring straight bearing type reverse balance flange connecting joint. The steel tower double-ring straight bearing type reverse balance flange connecting joint comprises an upper flange tower and a lower flange tower, wherein an upper stiffening plate is welded to the inner wall of the upper flange tower; a lower stiffening plate is welded to the inner wall of the lower flange tower; an upper balance ring is welded to the inner side of the upper stiffening plate; a lower balance ring is welded to the inner side of the lower stiffening plate; the upper surface of the upper stiffening plate is connected with an upper flange plate through structural adhesive; the lower surface of the lower stiffening plate is connected with a lower flange plate through structural adhesive; the upper flange plate and the lower flange plate are provided with bolt holes; and high-strength bolts penetrate through the upper flange plate and the lower flange plate through the bolt holes to connect the upper flange tower with the lower flange tower. Compared with the prior art, the steel tower double-ring straight bearing type reverse balance flange connecting joint has the advantages of being low in machining difficulty, convenient to install, excellent in fatigue resistance, high in circumferential rigidity and the like.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com