Corner punching die of door plate of mailbox

A technology of letter box and door panel, applied in the field of letter box production, can solve the problem of uneven seams of door panels, and achieve the effect of neat seams and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

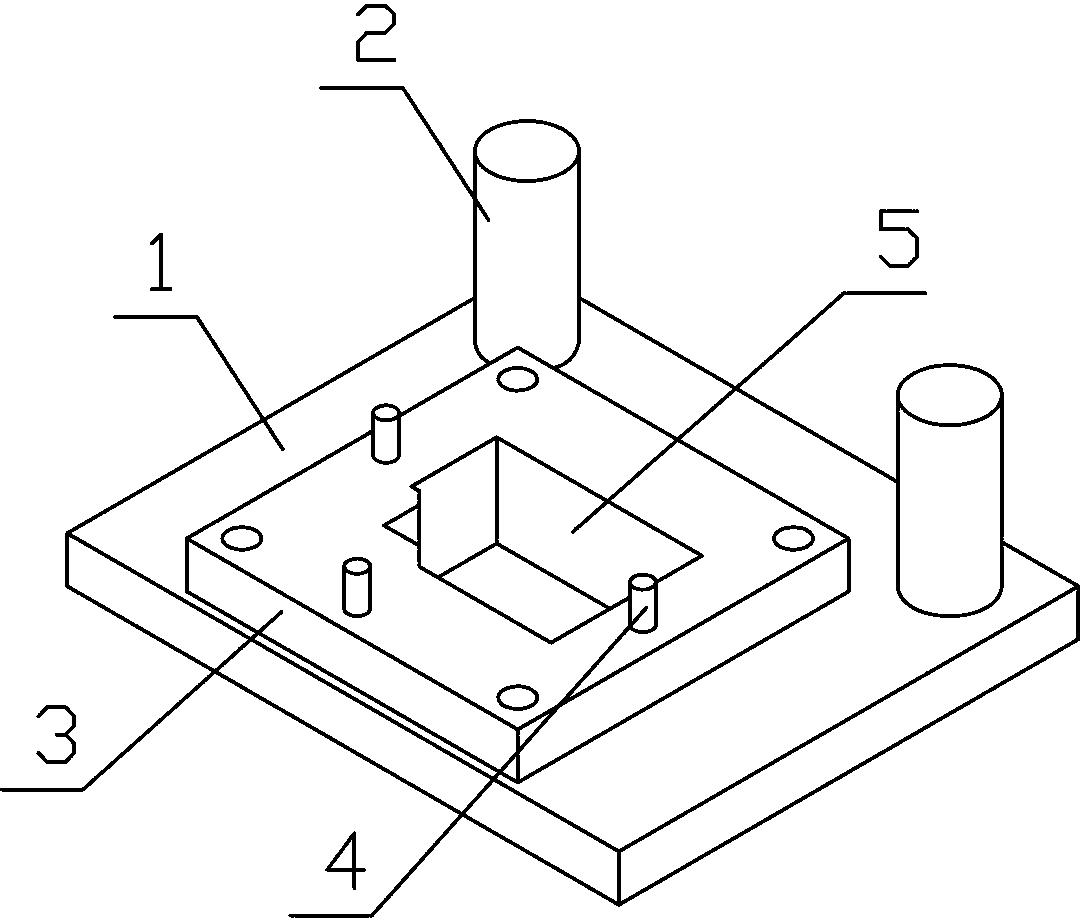

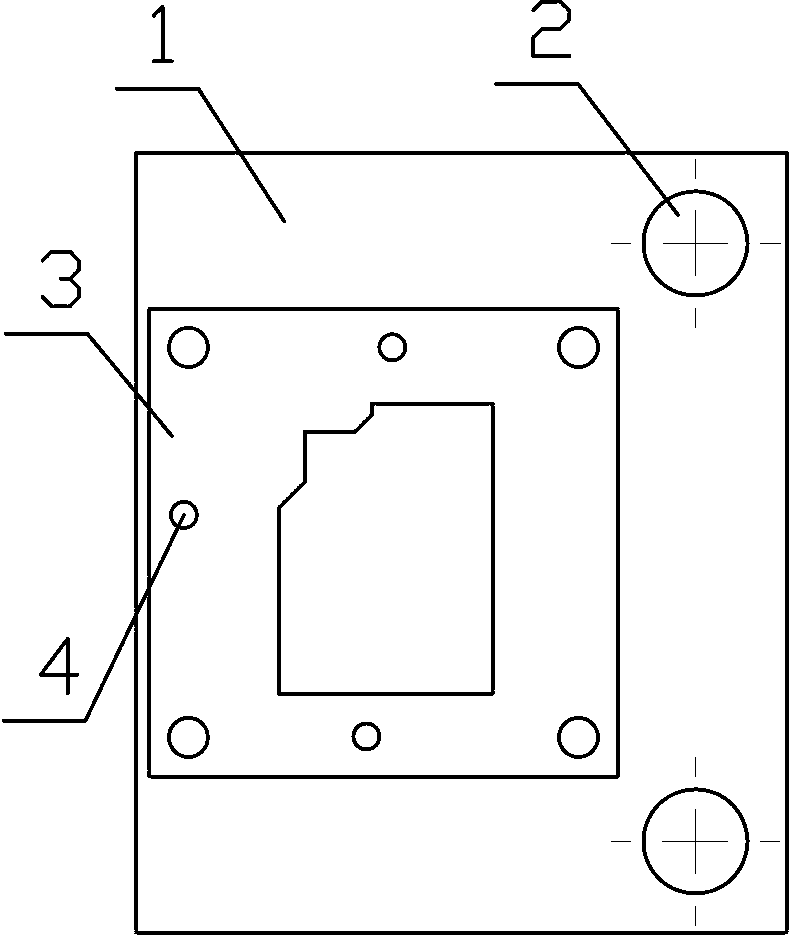

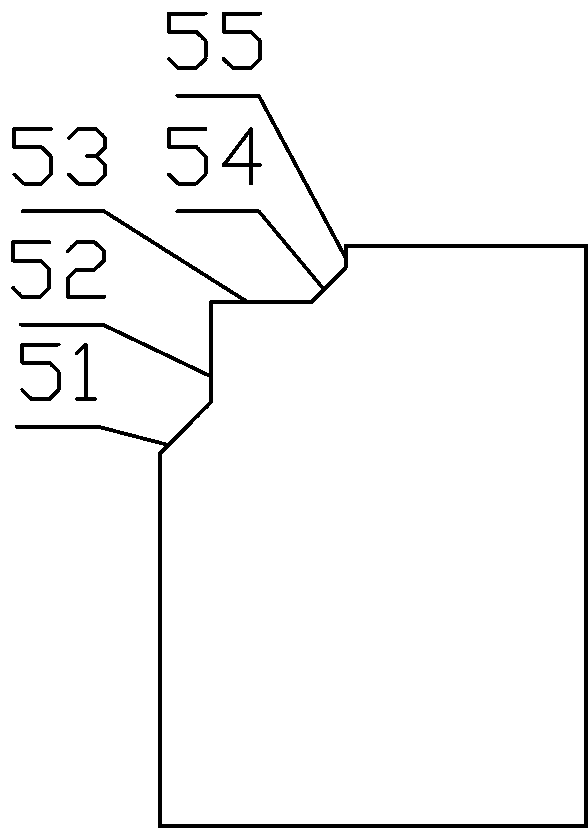

[0011] see Figure 1-4 , the present embodiment includes a die and a punch, the die includes a base 1, two positioning columns 2 are arranged on the upper edge of the base 1, a mold base 3 is mounted on the base 1 through bolts, and three mold bases 3 are provided with Locating pin 4, die hole 5 is arranged in the middle of mold base 3, and die hole 5 is generally rectangular, and wherein one angle is provided with the oblique section A51 that connects in sequence, straight section A52, straight section B53, oblique section B54, straight section C55; The punch includes a base 6, on which a mold core 8 is mounted. The shape of the mold core 8 is exactly the same as that of the die hole 5. The mold core 8 is covered with a cover plate 10, and the cover plate 10 is provided with three positioning pin holes 11, and the pins The positions of the holes 11 are in one-to-one correspondence with the positioning pins 4, and the cover plate 10 is connected with the mold core 8 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com