Adsorption-type ultrasonic tool head applied to the connection of polymer micro-devices

A micro device and tool head technology, applied in the field of polymer micro device assembly, can solve problems such as unconsidered problems, lack of parts clamping and fixing functions, etc., and achieves improved processing quality, uniform welding, and welding seams. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

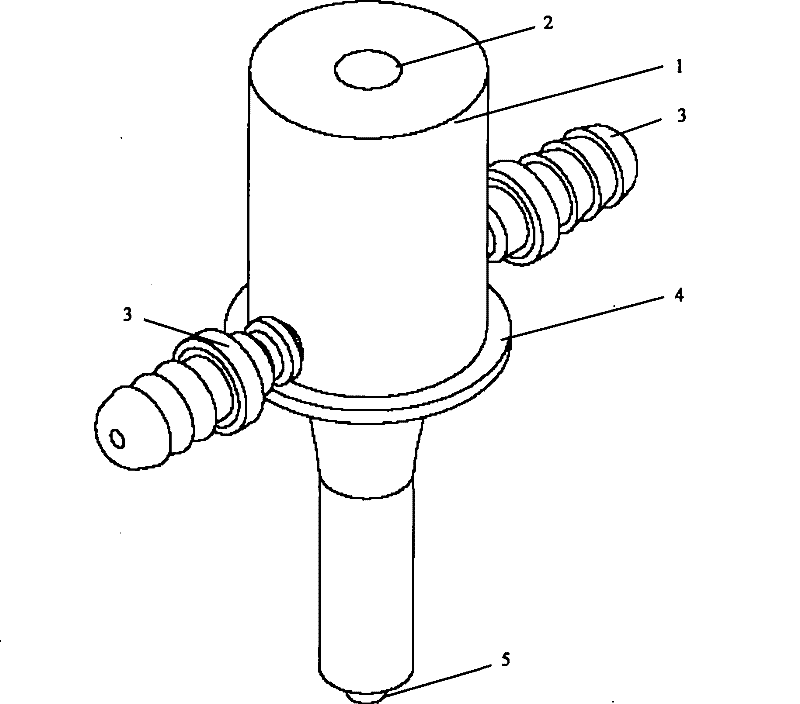

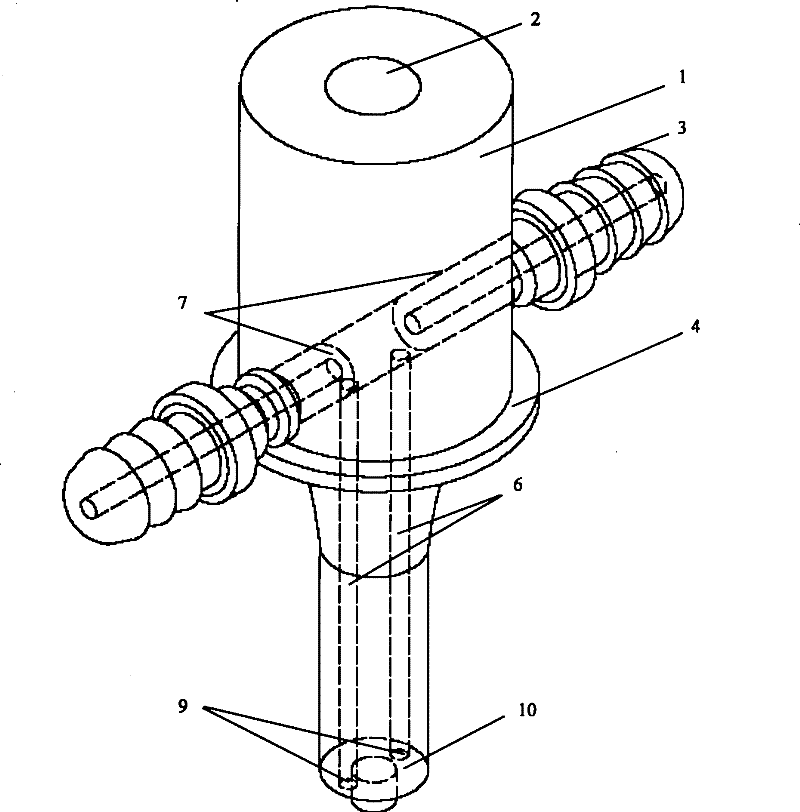

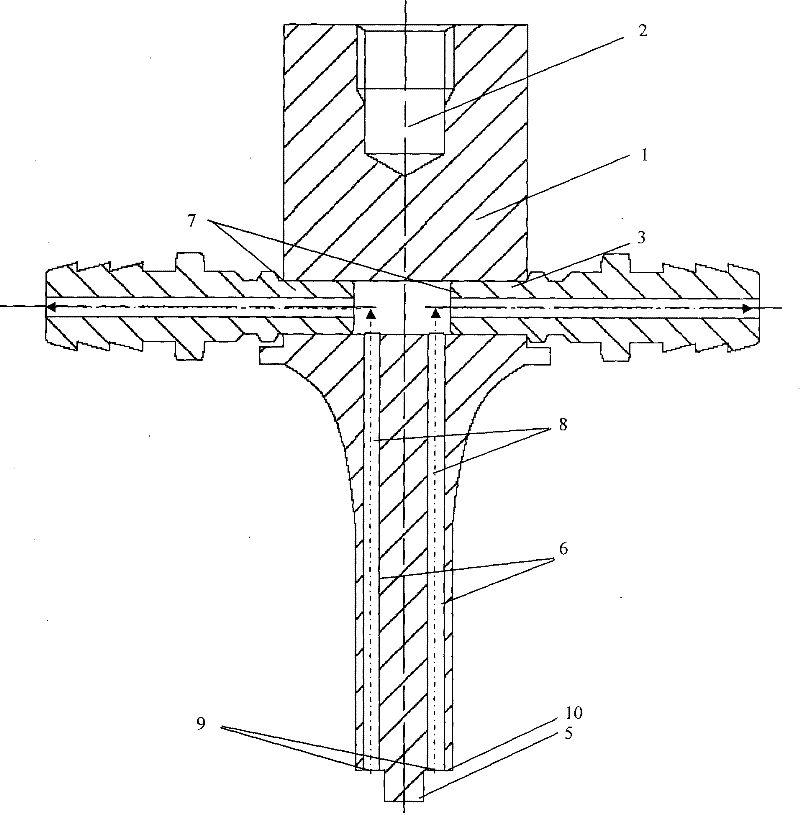

[0013] There is a threaded hole 2 on the top of the ultrasonic tool head main body 1 for connecting the transducer; the protruding position 4 in the middle is a node position, and the theoretical vibration amplitude of this position is zero, which is used to clamp and fix the entire ultrasonic tool head, and This position applies welding pressure to the device to be connected; at the end of the ultrasonic tool head is the ultrasonic radiation surface 10, and the design of the overall structure ensures that the amplitude of the surface is evenly distributed; there are device fixing structures 5 and adsorption clamping structures 9 on this surface, and the fixing structure 5 is located at the center of the ultrasonic radiation surface 10, and the adsorption and clamping structure 9 is symmetrically distributed on both sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com