A New High Efficiency Welded Plate Heat Exchanger

A technology of welding plates and heat exchangers, applied in the direction of indirect heat exchangers, heat exchanger types, heat exchange equipment, etc., can solve the heat exchange requirements that are not suitable for large processing capacity conditions, accidents at leakage points, and pressure bearing capacity Low-level problems, to achieve the effect of improving engineering adaptability, low operating costs, and high pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation and structure of a new type of high-efficiency welded plate heat exchanger proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. , features and their effects are described in detail below.

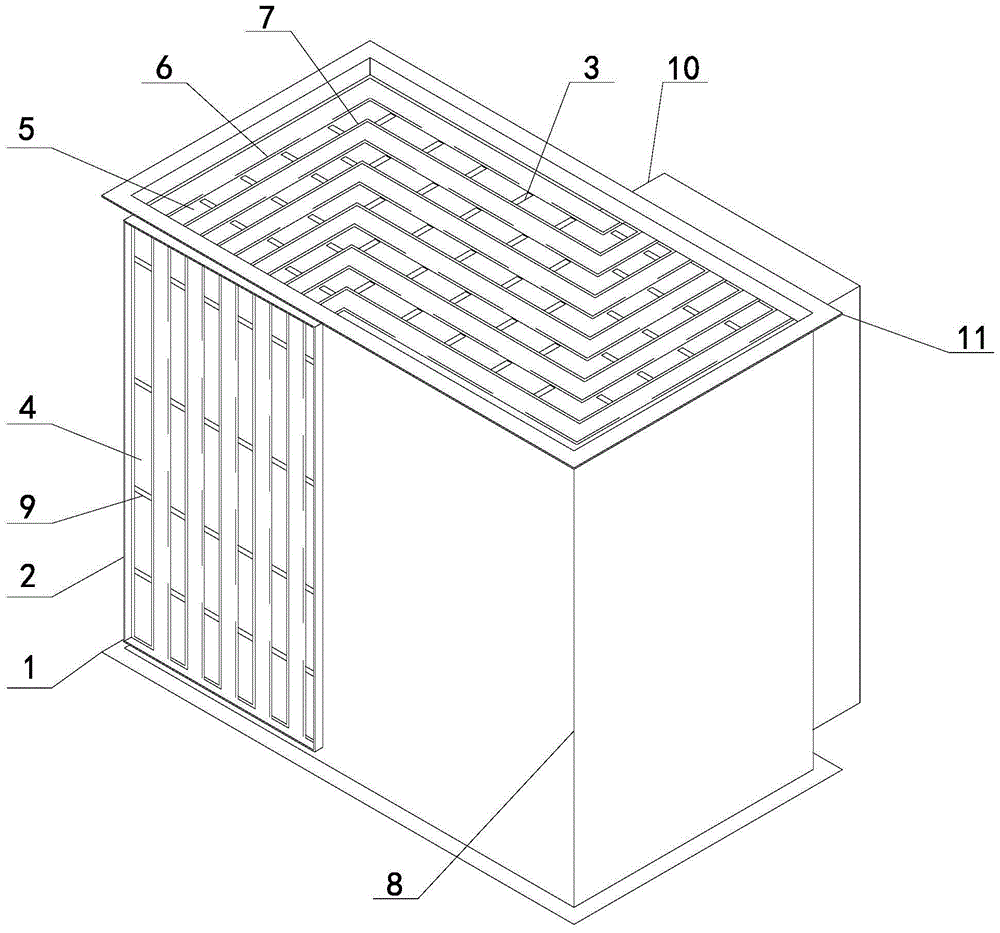

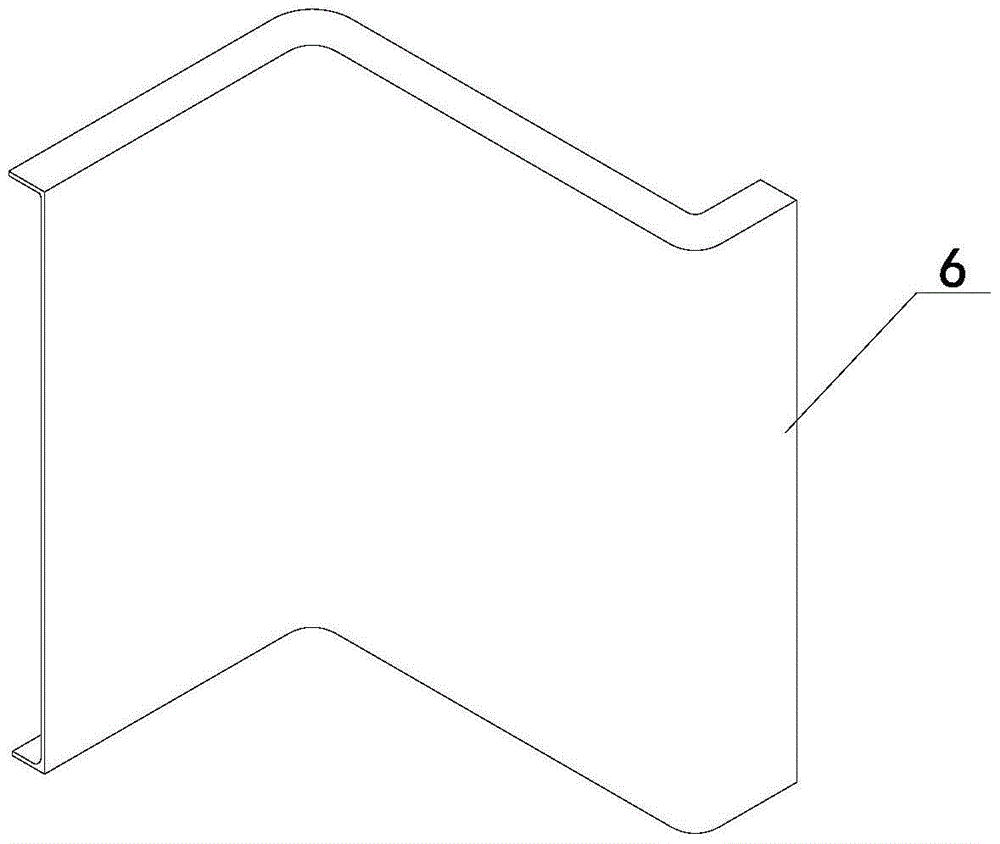

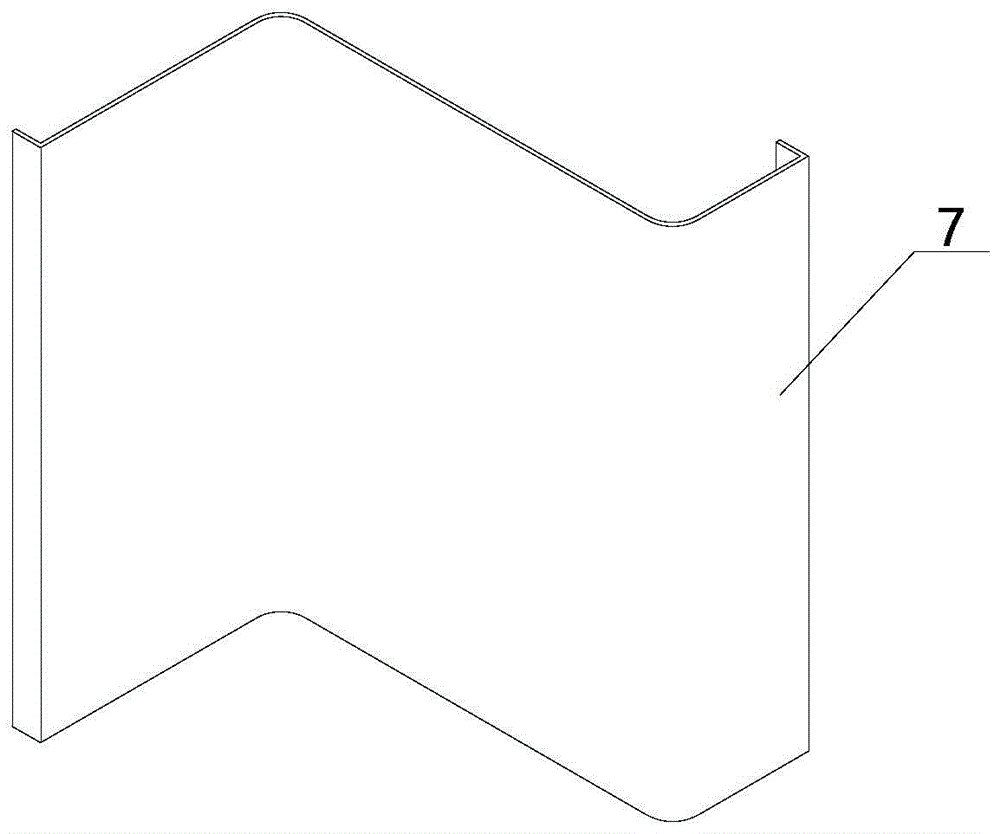

[0046] see figure 1 , is a new type of high-efficiency welded plate heat exchanger according to an embodiment of the present invention. It includes a shell 8 and a heat exchange plate assembly arranged in the shell 8. The shell 8 is provided with a fluid passage in the heat exchange plate assembly. Connected inlet and outlet, the housing 8 is generally non-cylindrical, the upper and lower ends of the housing 8 in the axial direction are respectively provided with a first fluid inlet 11 and a first fluid outlet 1, and the side of the hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com