Reverse balance flange connecting joint and manufacturing method and application thereof

A technology of connecting nodes and balancing method, applied in the direction of final product manufacturing, sustainable manufacturing/processing, wind power generation, etc., can solve the problems of difficulty in guaranteeing weld seam quality, large deviation of tower roundness, affecting tower installation, etc. It is convenient for mechanical flat welding, good rigidity, and the effect of ensuring welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

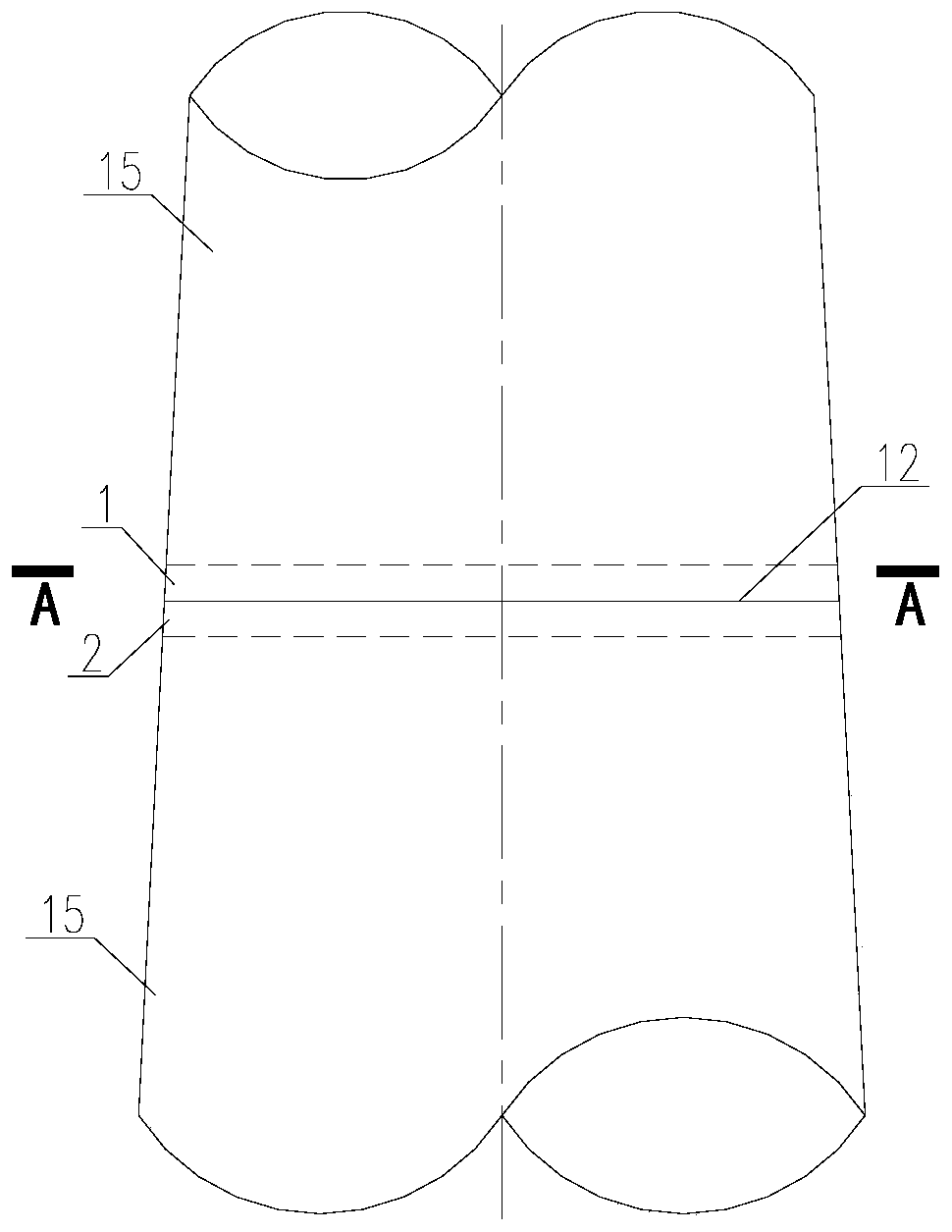

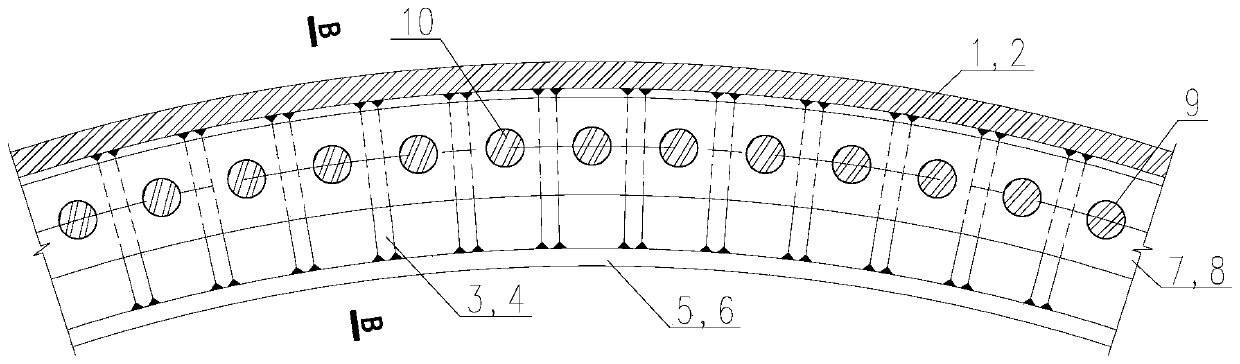

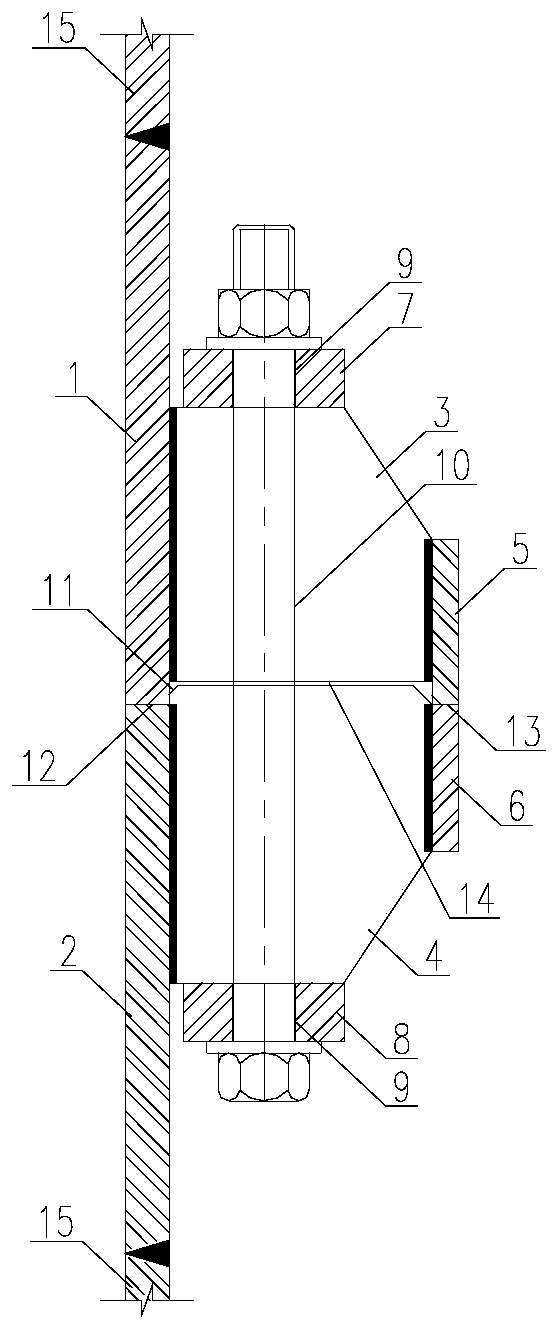

[0042] A steel tower double-ring direct support type reverse balance flange connection node, such as figure 1 As shown, including the upper flange tower tube 1 and the lower flange tower tube 2, the contact surface between the upper flange tower tube 1 and the lower flange tower tube 2 is the tower tube butt joint surface 12, the upper flange tower tube 1 and the lower flange tower tube 2 The lower flange tower tube 2 is welded with the corresponding tower tube body 15 respectively, and the taper of the upper flange tower tube 1 and the lower flange tower tube 2 is the same as that of the tower tube body 15 . Such as figure 2 As shown, the inner wall of the upper flange tower 1 is welded with an upper stiffener 3, the inner wall of the lower flange tower 2 is welded with a lower stiffener 4, the upper surface of the upper stiffener 3 is connected with an upper flange 7 through structural glue, and the lower stiffener The lower surface of the plate 4 is connected with the low...

Embodiment 2

[0061] A steel tower double-ring direct support type reverse balance flange connection node, such as figure 1 As shown, including the upper flange tower tube 1 and the lower flange tower tube 2, the contact surface between the upper flange tower tube 1 and the lower flange tower tube 2 is the tower tube butt joint surface 12, the upper flange tower tube 1 and the lower flange tower tube 2 The lower flange tower tube 2 is welded with the corresponding tower tube body 15 respectively, and the taper of the upper flange tower tube 1 and the lower flange tower tube 2 is the same as that of the tower tube body 15 . Such as figure 2 As shown, the inner wall of the upper flange tower 1 is welded with an upper stiffener 3, the inner wall of the lower flange tower 2 is welded with a lower stiffener 4, the upper surface of the upper stiffener 3 is connected with an upper flange 7 through structural glue, and the lower stiffener The lower surface of the plate 4 is connected with the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com