A thin steel plate continuous tailor welding device and tailor welding method

A thin steel plate, continuous technology, applied in the thin steel plate continuous tailor welding device and the field of tailor welding, can solve the problems of inconvenient use for downstream users, difficult to guarantee welding quality, loss of use value, etc., to achieve good flatness, good welding quality, welding speed-up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

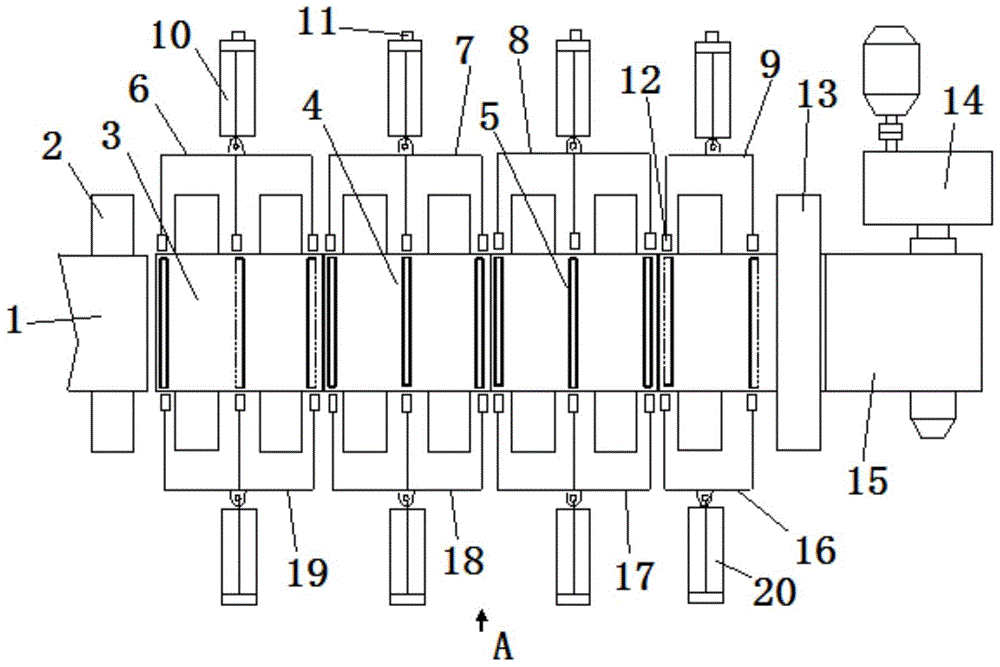

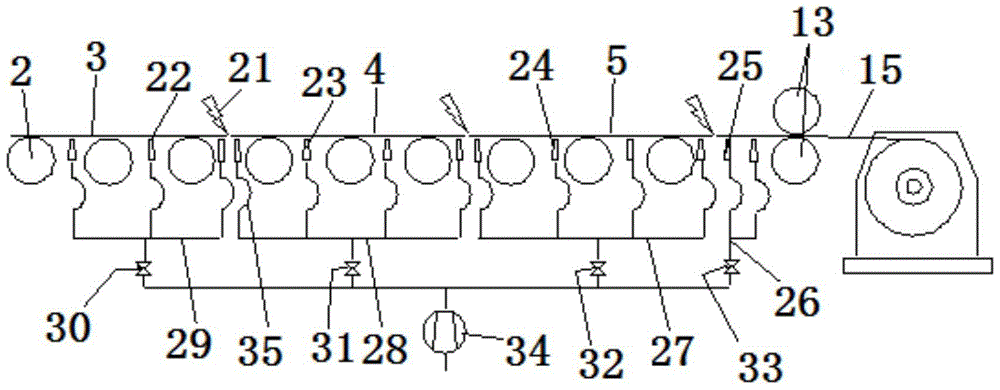

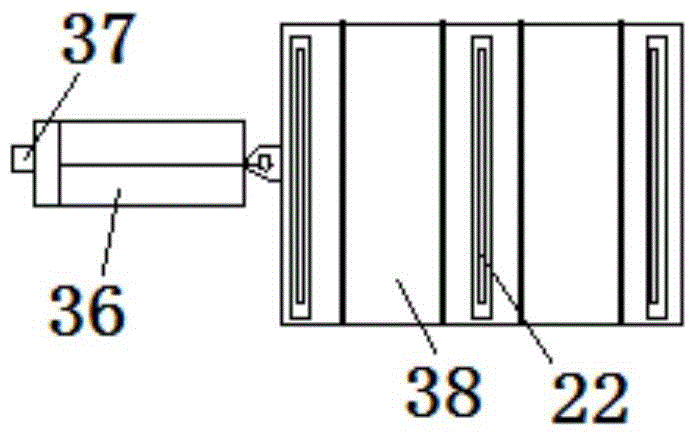

[0031] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

[0032] like figure 1 and figure 2 As shown, the thin steel plate continuous tailor welding device includes a conveying roller table 2 for conveying the thin steel plates 3, 4, 5 to be welded, a centering device arranged on both sides of the conveying roller table 2, and a centering device arranged on the thin steel plates 3, 4 to be welded. , 5 below the vacuum positioning device. The conveying roller table 2 includes a plurality of conveying rollers driven by driving motors to realize the conveyance of the thin steel plates 3, 4 and 5 to be welded, the centering device realizes the width direction positioning of the thin steel plates 3, 4 and 5 to be welded, and the vacuum positioning device realizes Fixing of the thin steel plates 3, 4, and 5 to be welded and positioning along the leng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com