Decorative strip guiding mechanism and stitching machine adopting same

A guiding mechanism and decorative strip technology, which is applied in the direction of cloth feeding mechanism, sewing machine components, textiles and papermaking, etc., can solve the relatively high requirements for presser foot processing and installation accuracy, the difficulty of sewing three-layer shoe upper materials for decorative strips, and the difficulty Adjust the position of the decorative strip and other issues to achieve the effect of improving sewing efficiency and sewing quality, improving sewing quality, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to further explain the technical solution of the present invention, the following will be described in detail in conjunction with the examples.

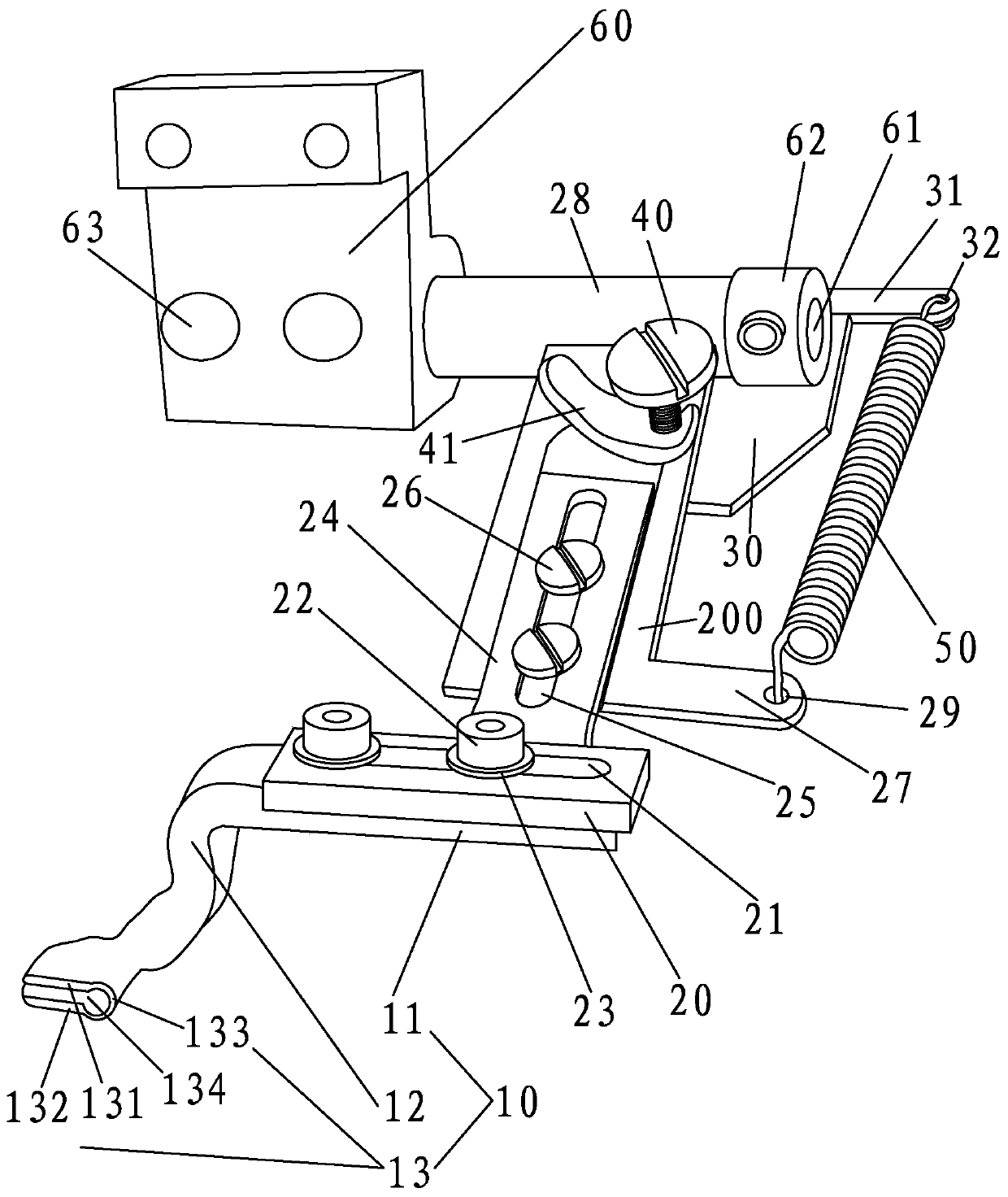

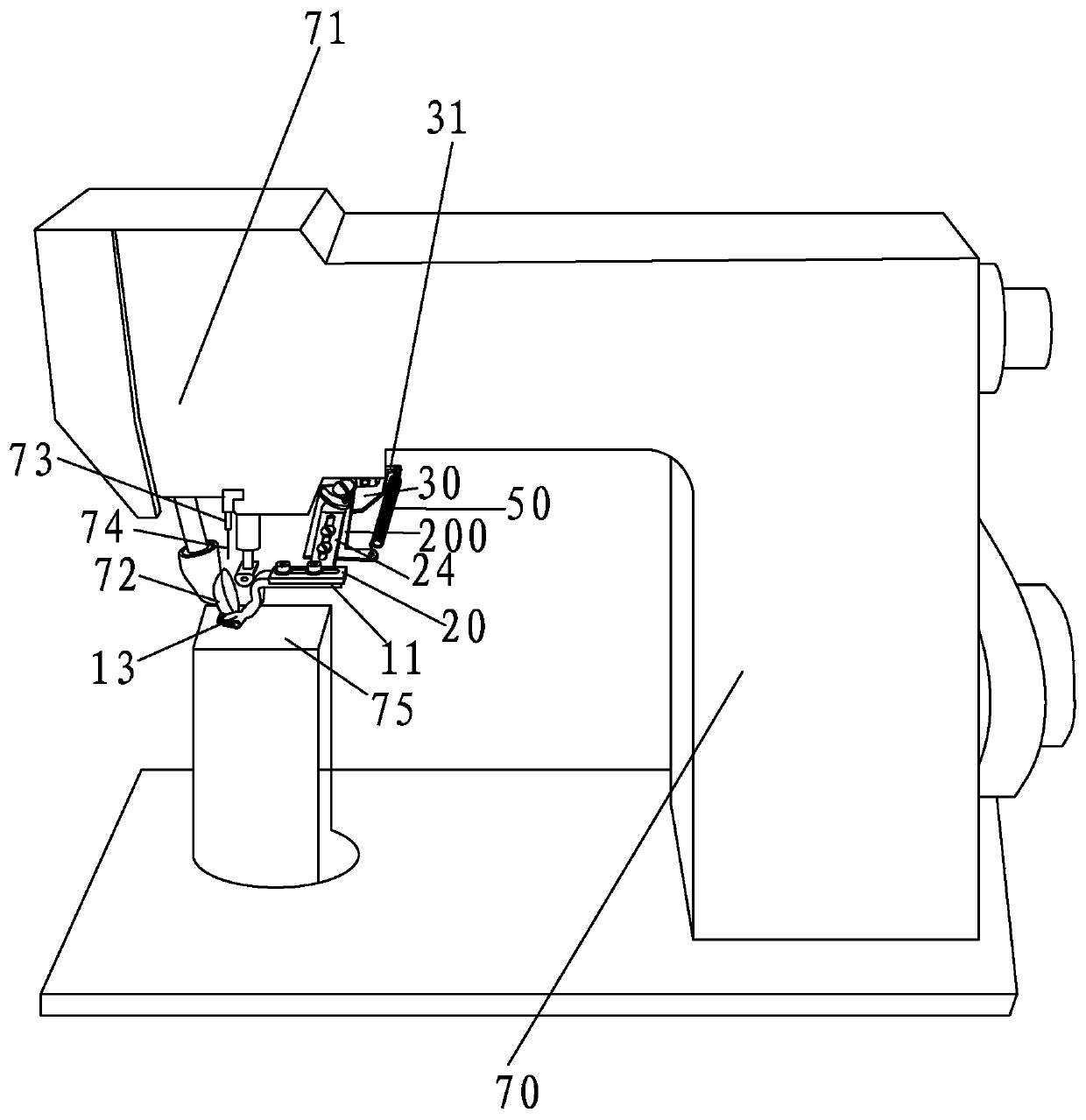

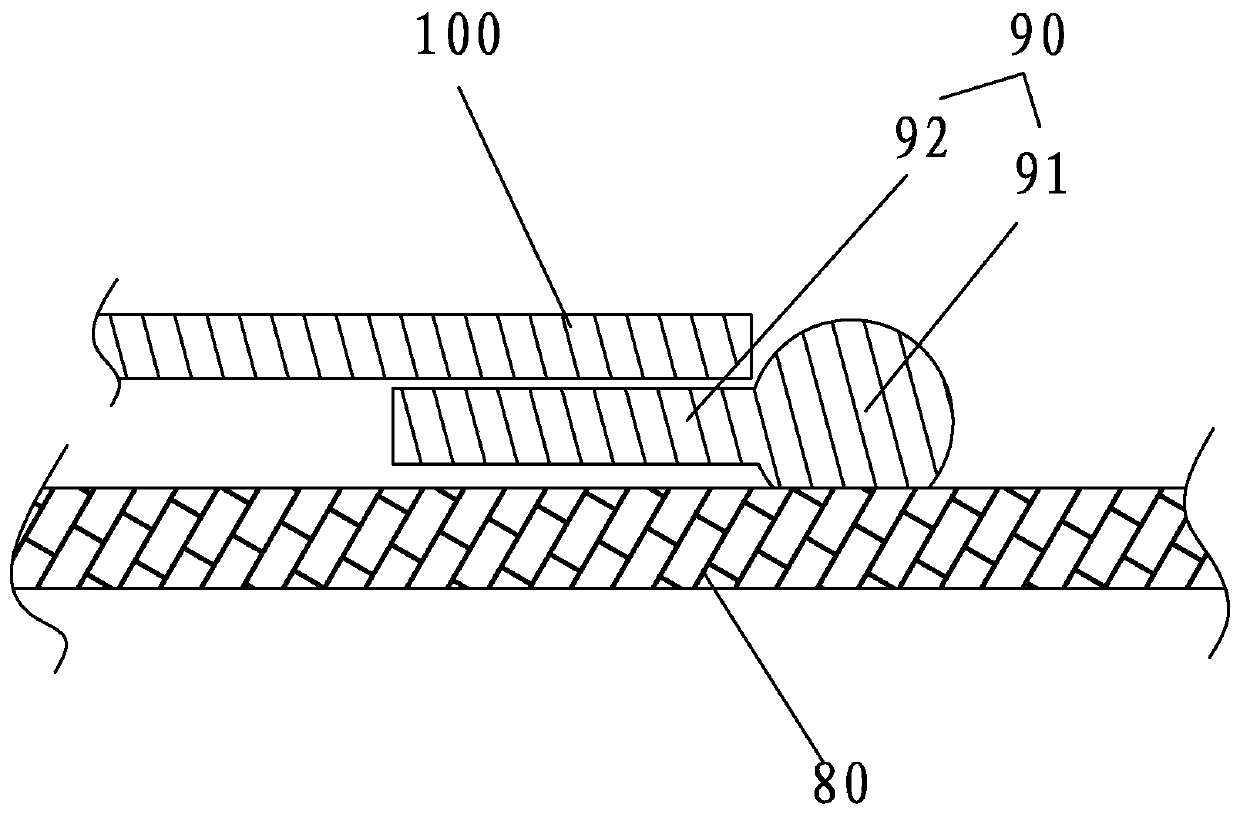

[0043] refer to Figure 1 to Figure 3 , the decorative strip guide mechanism, including the installation part 60 installed on the sewing machine main body 70 and the guide block 10 for guiding the decorative strip 90, the guide block 10 is provided with a guide groove 134, and the extension direction of the guide groove 134 is the longitudinal direction ( That is, the running direction of the decorative strip 100 in the work engineering, that is, the front and rear directions to be described below), is perpendicular to the transverse direction and transverse to the direction along the horizontal direction. The present invention also includes a first adjustment block 20 and a second adjustment block 200. Both the first adjusting block 20 and the second adjusting block 200 are in the shape of a plate, the guide block 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com