A non-taper laser processing method

A laser processing method and a technology without taper, which is applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of uncontrollable slit taper, low quality, and large slit roughness, etc., so as to improve the finish and reduce the Roughness, the effect of improving manufacturing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

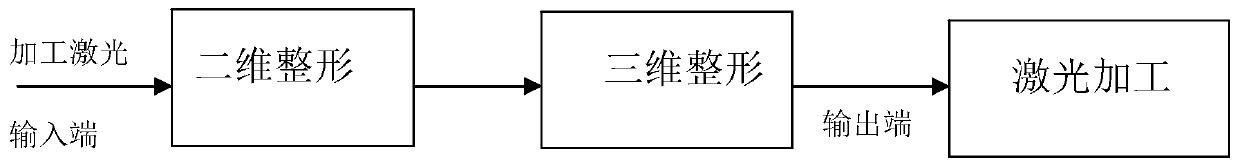

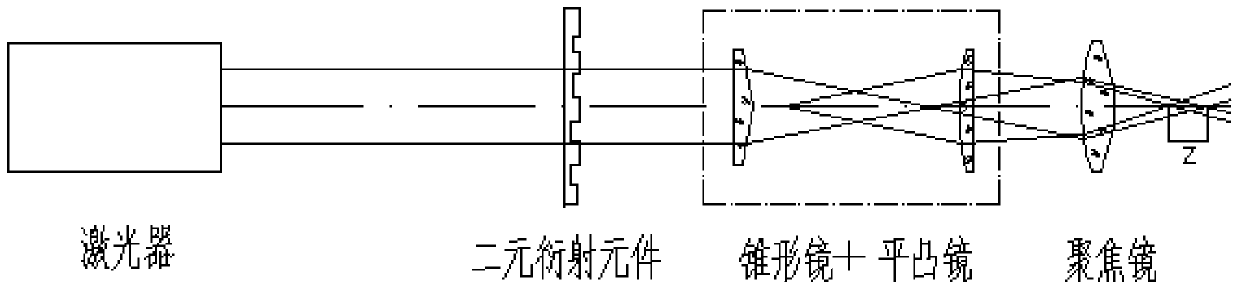

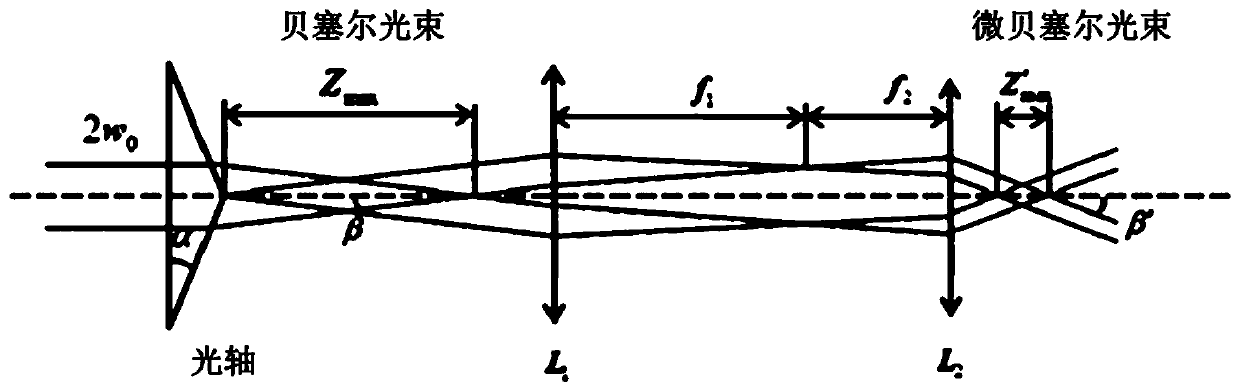

[0029] The invention provides a laser processing method. The long-focus deep rectangular flat-top light realized by the three-dimensional space compound shaping method is used for the first time to solve the laser thick plate cutting process. After a large number of process tests, the applicant conducted interactive tests and analysis on relevant parameters such as laser power, scanning speed, cutting path planning, focus position, focus spot size, and focus depth, and obtained the effect of laser focus depth on laser kerf taper, And the roughness has a very good improvement effect. The invention adopts a three-dimensional space compound shaping method to shape the laser beam into a rectangular flat-top light with a long focal depth for thick plate cutting, so as to realize high-quality laser cutting and manufacturing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com