Automatic submerged-arc welded H-shaped steel production method

A production method, submerged arc welding technology, which is applied in the field of profile processing, can solve the problems of lack of flue gas purification process, low degree of automation, and unfavorable production efficiency, and achieve the effects of stable connection, simple operation, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

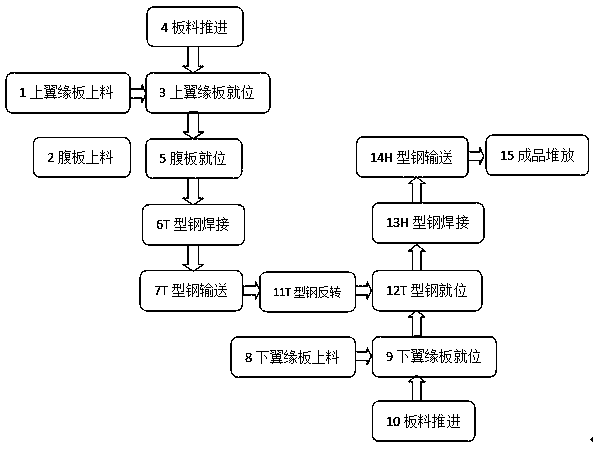

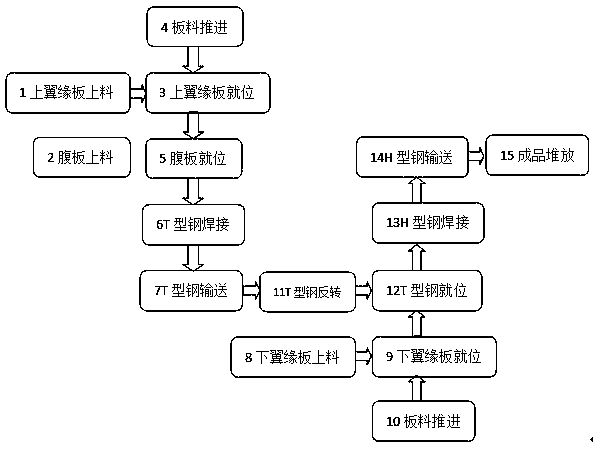

[0039] Embodiment 1: with reference to attached figure 1 , a production method of automatic submerged arc welding H-shaped steel, the improvement is: comprising the following steps:

[0040] S1. Feeding: use the gantry crane to hoist the steel plates to the lifting platforms of the upper and lower flange plates and web plates respectively;

[0041]S2. Push cutting of the upper flange plate: the large pusher bar pushes the steel plate to the predetermined position, and the fixed size is the width of the upper flange plate from the cutting edge to the edge of the plate. The plasma cutting trolley cuts, and the large pusher bar continues to move forward Push the steel plate, and the plasma cutting trolley cuts again, and pushes and cuts in this way until the cut upper flange plate is pushed to the predetermined position of the upper flange plate conveying platform;

[0042] S3. Conveying of the upper flange plate: the small push plate in the upper flange plate conveying platform...

Embodiment 2

[0055] Embodiment 2: On the basis of Embodiment 1, in S1, the lifting platform is controlled by a drive motor, a reducer, a steering gear and an elevator, so as to adjust the height of the steel plate and push the steel plate.

Embodiment 3

[0056] Embodiment 3, on the basis of Embodiment 1 or 2, in S2, after the steel plate is lifted to a predetermined height by the lifting platform, the large pusher pushes the steel plate to a distance from the edge of the plate under the drive of the motor and the lead screw. The cutting position of the width of the upper flange plate is cut out by the plasma cutting trolley to a predetermined width of the upper flange plate; each time a piece of the upper flange plate is cut, the push bar continues to push the steel plate forward to the width of an upper flange plate, Cutting again; in the process of pushing the upper flange plate, push the cut upper flange plate to the upper flange plate conveying platform one after another;

[0057] In S4, after the steel plate is lifted to a predetermined height by the lifting platform, the large pusher pushes the steel plate to the cutting position of one web width away from the edge of the plate under the drive of the motor and the lead sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com