Automatic suction cleaner

A technology for automatic vacuum cleaners and vacuum cleaners, which is applied in the direction of vacuum cleaners, cleaning equipment, household appliances, etc., and can solve the problems of insufficient cleaning and low power of vacuum cleaners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

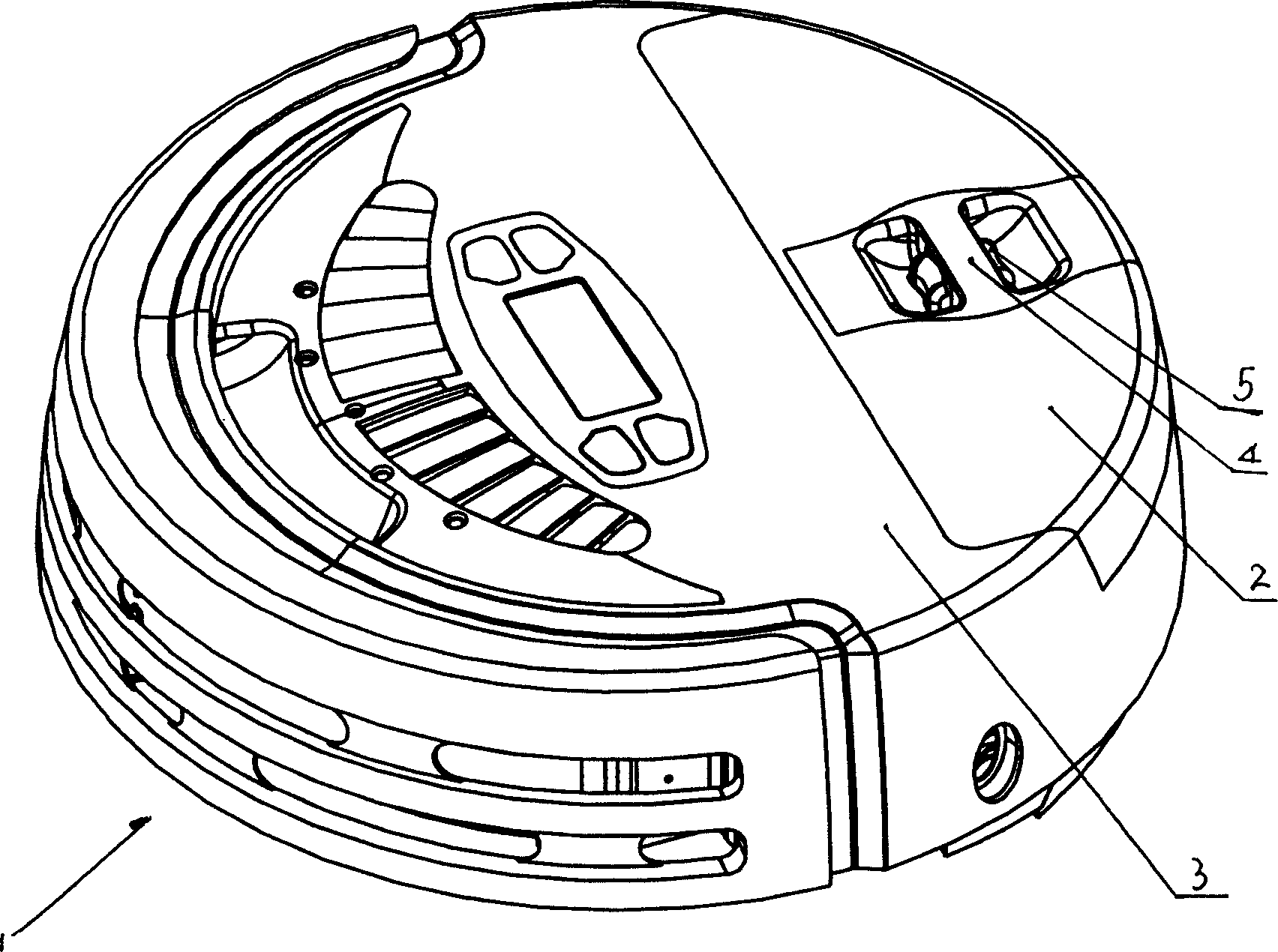

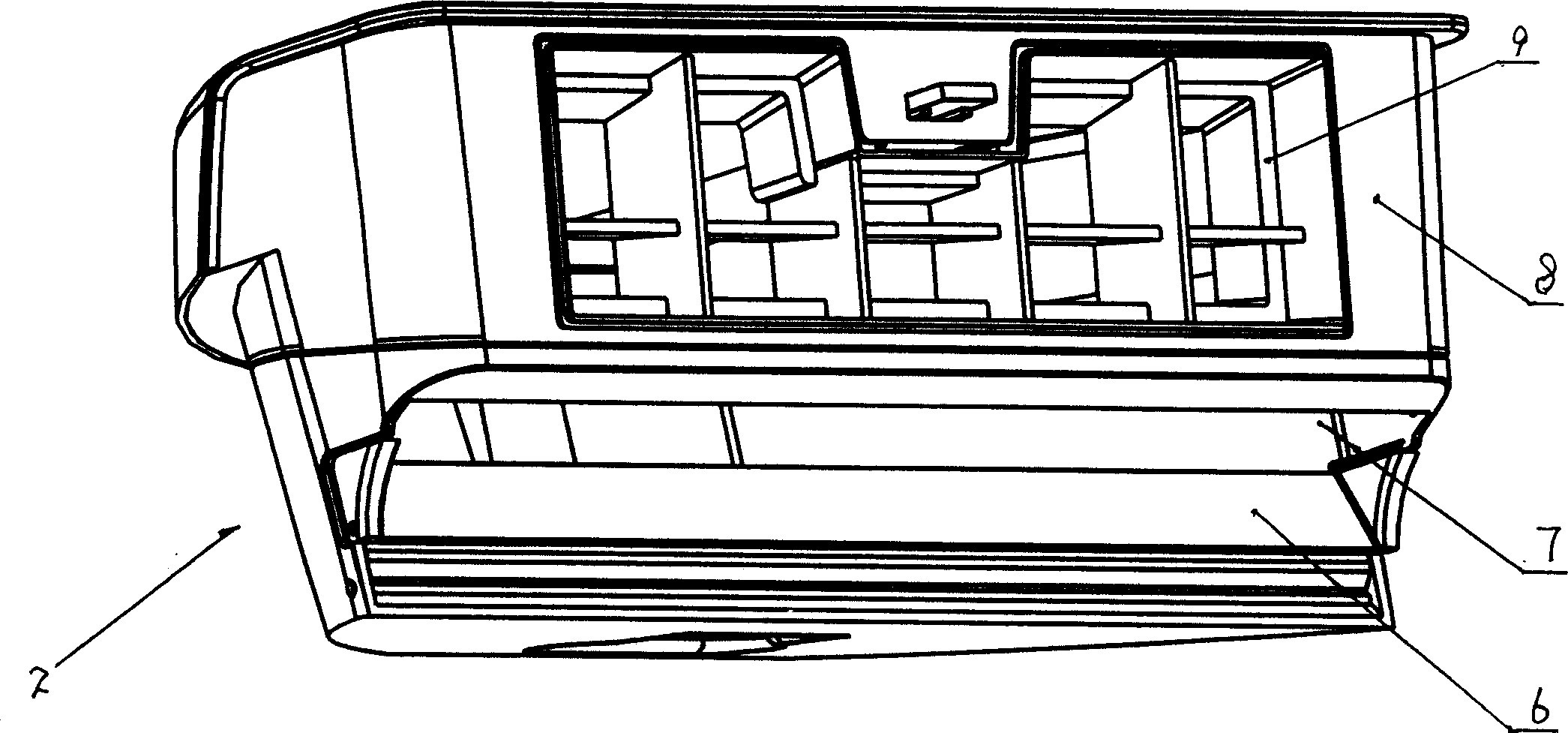

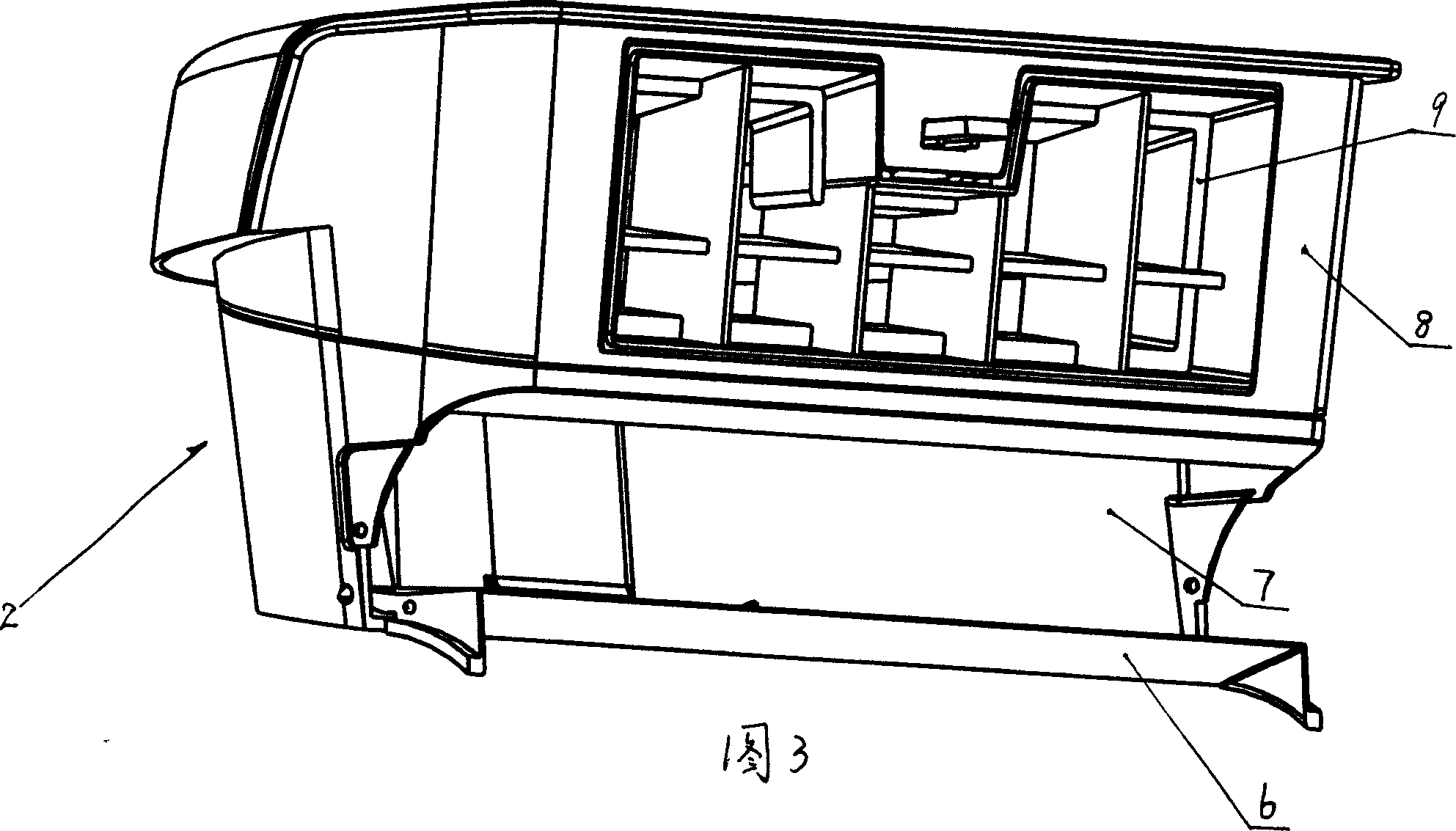

[0012] Referring to the drawings, an automatic vacuum cleaner includes a vacuum cleaner body 3 and a dust cylinder 2 arranged on the vacuum cleaner body 3 . A negative pressure chamber 8 is arranged inside the dust cylinder 2, and the negative pressure chamber 8 communicates with the dust suction inlet 11 at the bottom. The bottom of the vacuum cleaner body 3 is provided with a ground brush 10, the ground brush 10 is connected to the power drive mechanism, and the bottom of the dust cylinder 2 is provided with a dust sweeping inlet 12, which is adjacent to the dust sweeping inlet 12. And against described ground brush 10. The ash storage chamber 7 is also arranged in the dust cylinder 2, and the ash sweeping inlet 12 communicates with the ash storage chamber 7. The automatic vacuum cleaner sucks the small particles of dust into the negative pressure chamber 8 through the vacuum cleaner inlet 11, and at the same time, the ground brush 10 sweeps the large particles of dust into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com