Rotary optical coder

An optical encoder and coding technology, applied in the field of rotary optical encoders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

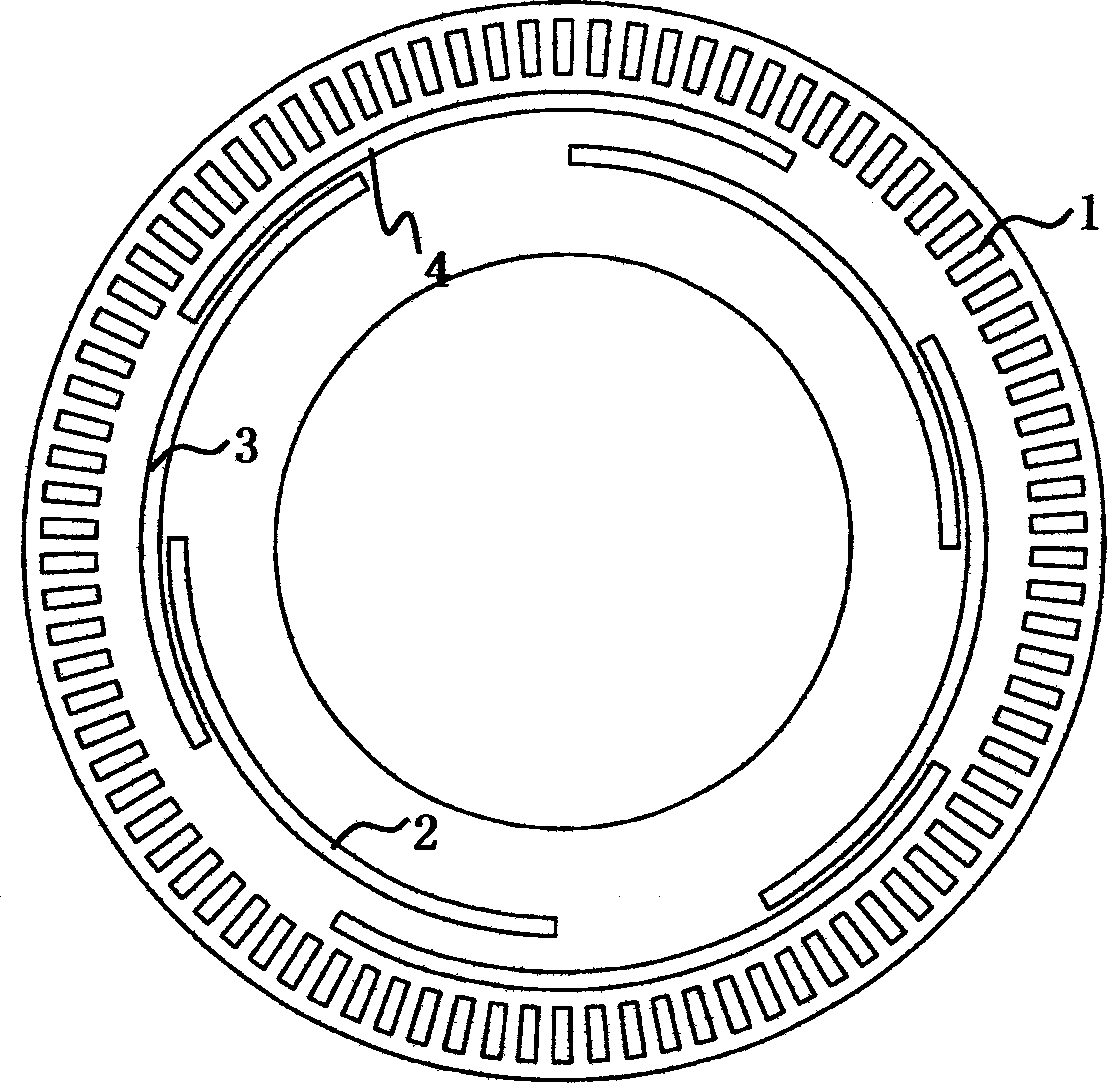

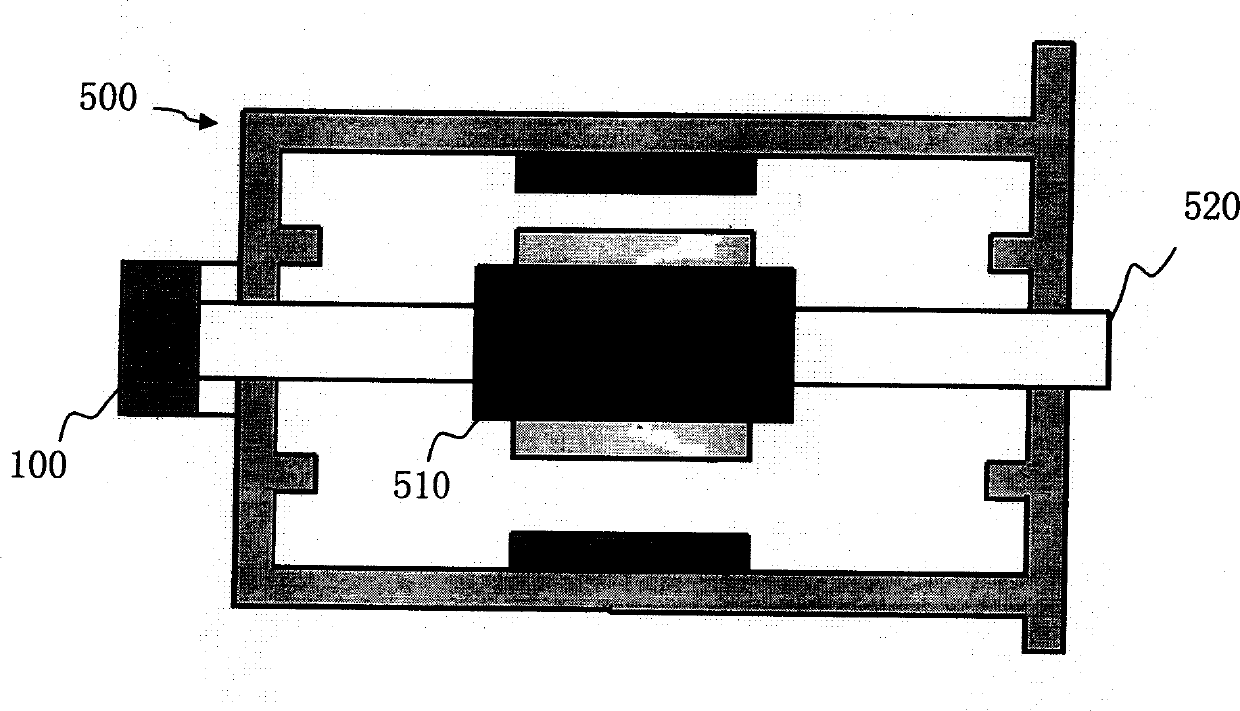

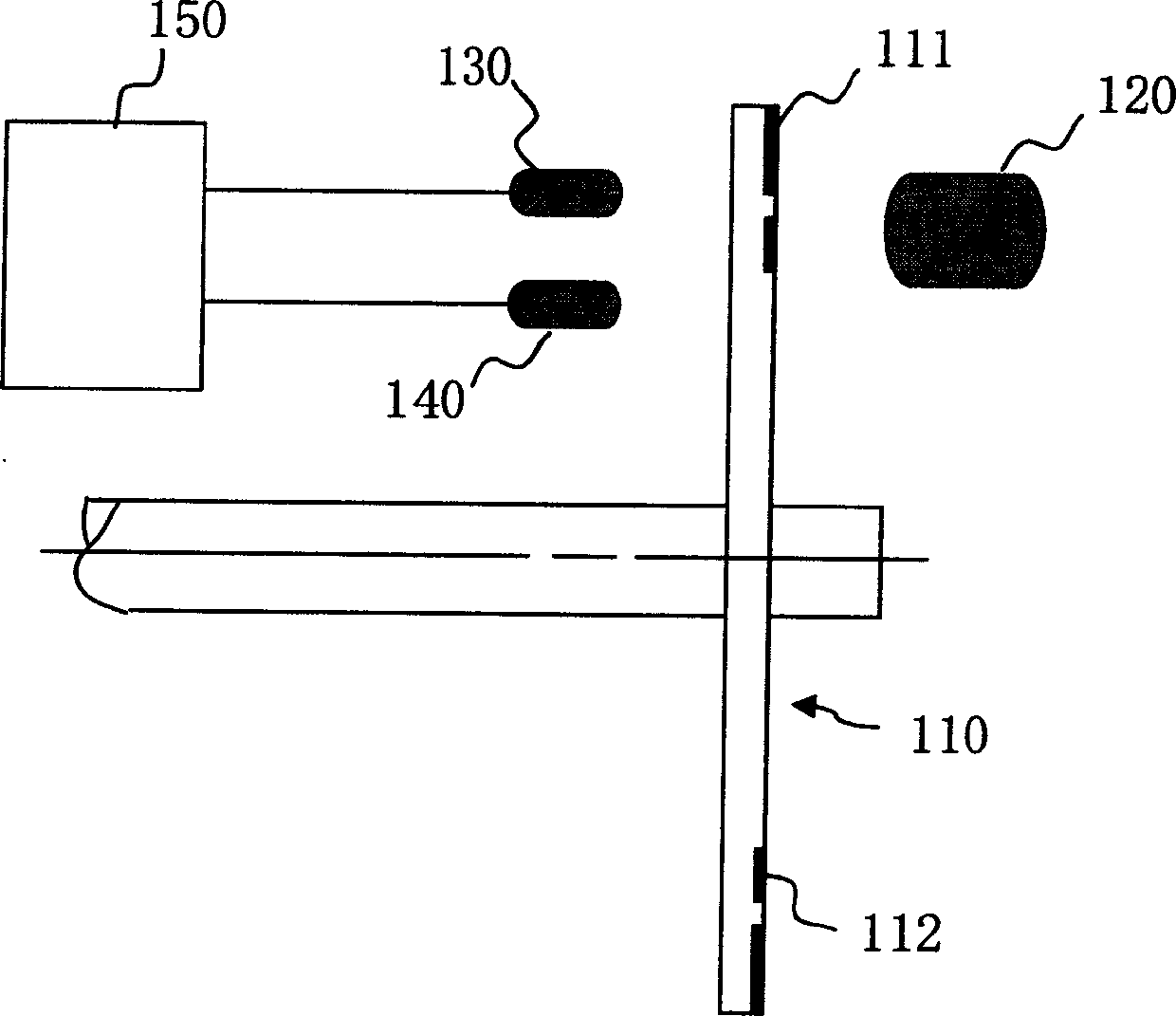

[0069] Please refer to FIG. 2 and FIG. 3 , the rotary optical encoder 100 provided by the present invention is applied to a permanent magnet motor 500 to provide the magnetic pole position of the rotor 510 . The rotary optical encoder 100 includes an optical transmitter 120 , an encoder wheel 110 , two optical sensors 130 and 140 , and a processing circuit 150 . Wherein, the code disc 110 is coupled to the rotating shaft 520 of the permanent magnet motor 500, and when the rotor 510 rotates, it will drive the code disc 110 to rotate. The code disc 110 is regularly engraved with fine slits 111 and code tracks 112. It is permeable to light, and a light emitter 120 and two light sensors 130 and 140 are respectively installed on both sides of the code disc 110 . When the encoder disk 110 rotates, the light emitter 120 provides the light source, and the amount of light sensed by the light sensors 130 and 140 changes synchronously with the light-transmitting lines, and the light inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com