Feeding device for powdery raw materials

A technology for feeding devices and raw materials, applied in the directions of transportation, packaging, chute, etc., can solve the problems affecting production and processing, powder deposition, small powder particles, etc., to avoid energy waste, prevent powder overflow, and ensure normal operation. The effect of running

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

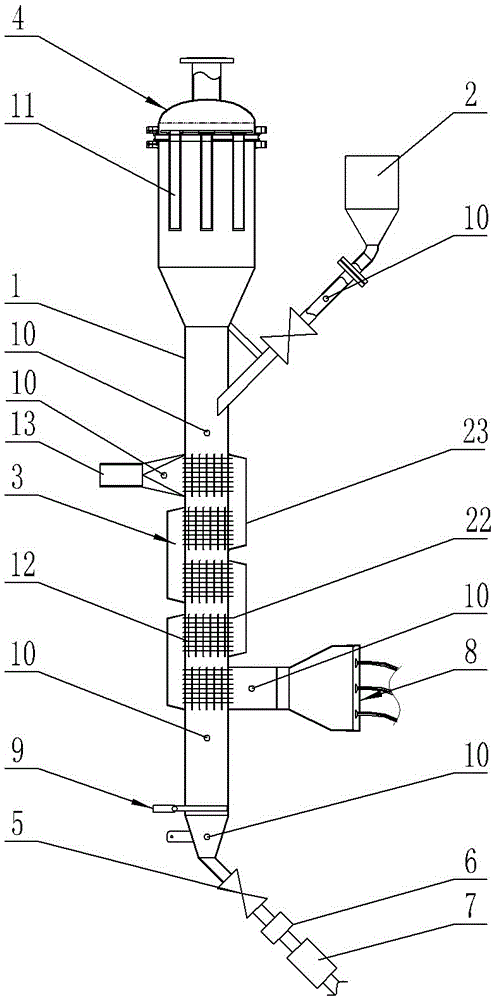

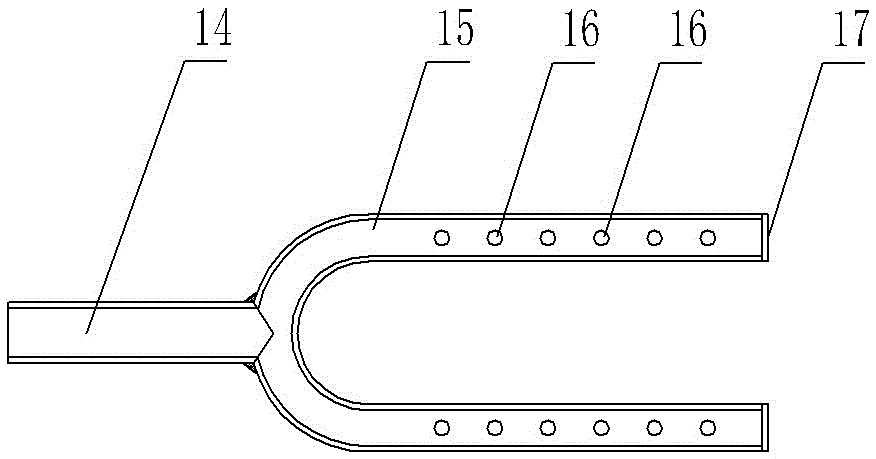

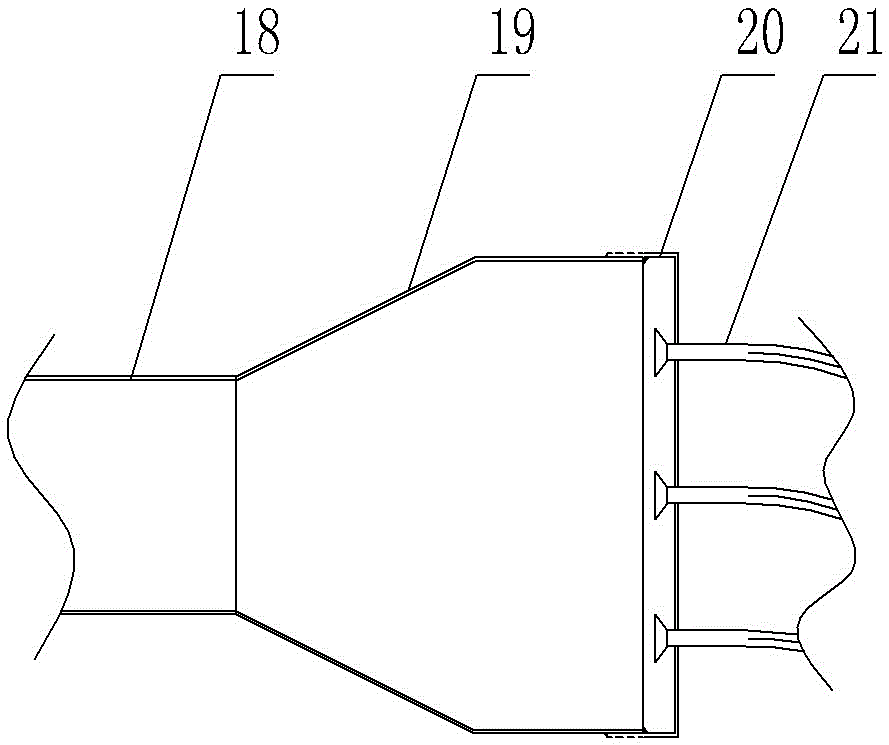

[0019] Such as figure 1 , figure 2 with image 3 As shown, it includes a housing 1, a feed hopper 2 is provided on the upper part of the housing 1, and a shut-off valve 5, a controllable switch 6 and a flow measuring instrument 7 connected in sequence are arranged on the feeding pipe at the bottom of the housing 1. The inner cavity is provided with several horizontally arranged heat exchange tubes 22 and vertically arranged baffles 12, two adjacent rows of baffles 12 are arranged alternately, and several heat exchange tubes 22 pass through the inner cavity of the shell in the horizontal direction and pass through The trough-shaped connectors 23 sealed on the outer periphery of the shell are connected in series to form the heat exchange device 3 , the heat exchange medium inlet end of the heat exchange device 3 is set at the lower part of the shell 1 , and the heat exchange medium outlet 13 is set at the upper part of the shell 1 , The heat exchange tube 22 intersects the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com