Anti-burn method for recording and reproducing system

A regeneration system and recording technology, applied in digital recording/reproduction, magnetic recording, data recording, etc., can solve the problems of read/write head position offset, poor system design, wrongly written data, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

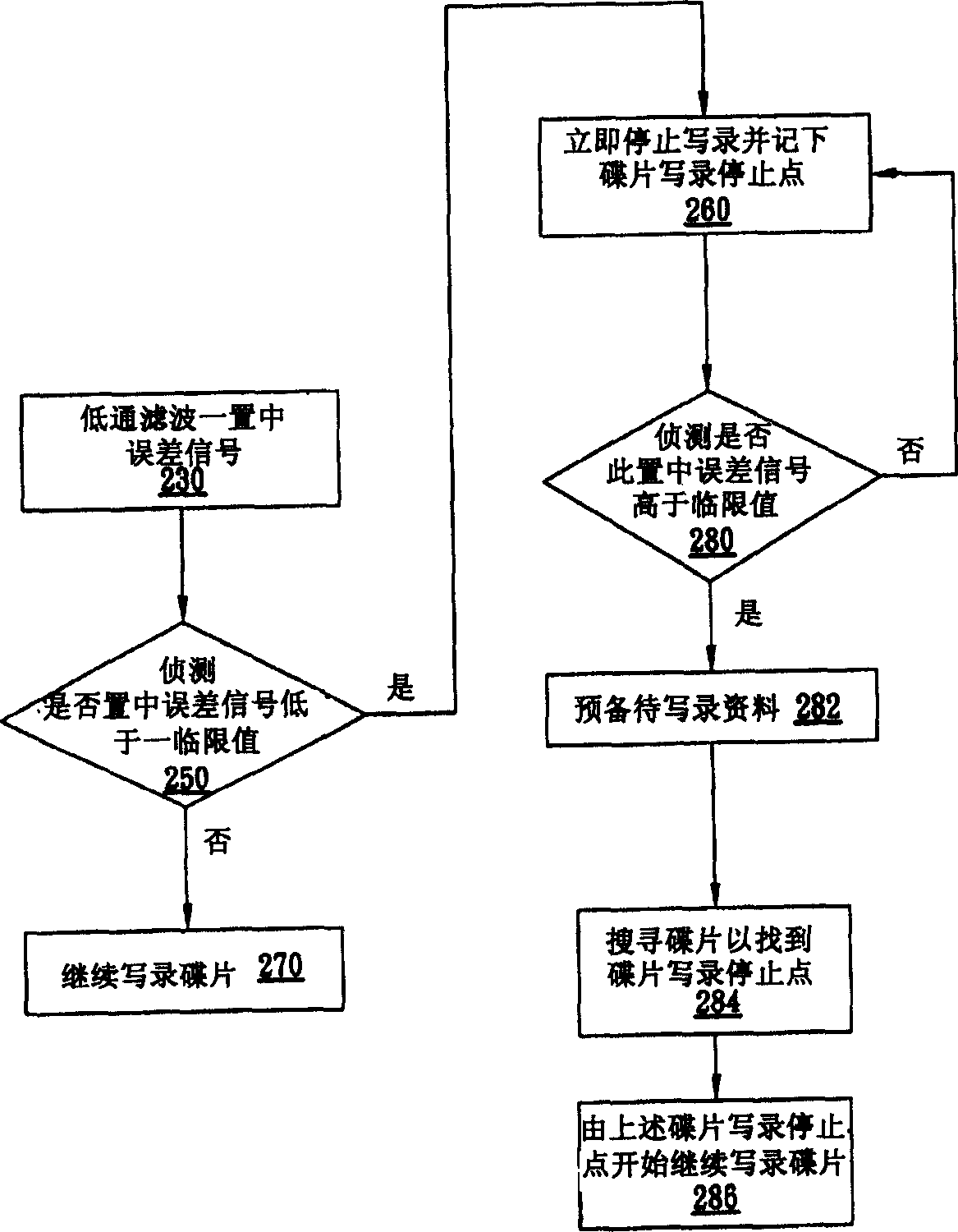

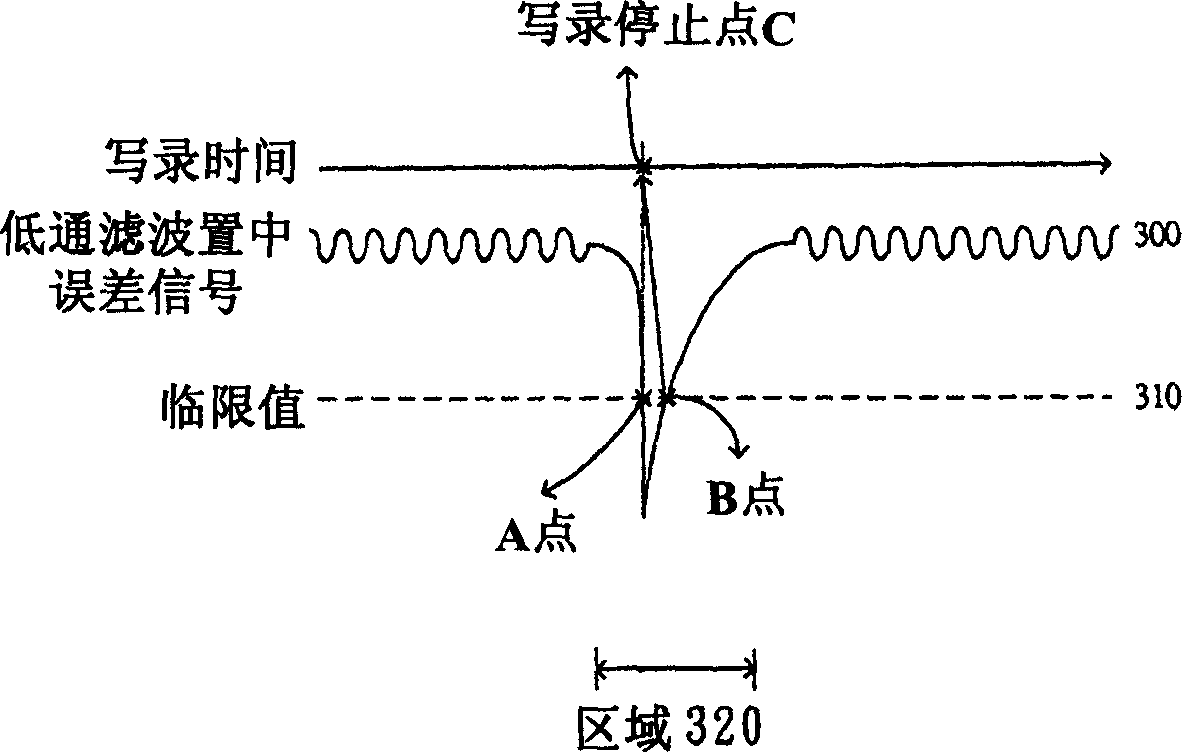

[0029] The invention provides a method for preventing burnout of a recording and reproducing system, so as to avoid recording errors caused by mechanical factors. Among them, when the recording and reproduction system encounters a sudden vibration, or under rare conditions such as old system equipment or poor design, the recording operation can be stopped to avoid data recording errors.

[0030] Preferred embodiments of the present invention will be described in detail as follows. However, the present invention can also be widely implemented in other embodiments except for the content described in detail, and the scope of the present invention is not limited, which is subject to the scope of subsequent patent applications.

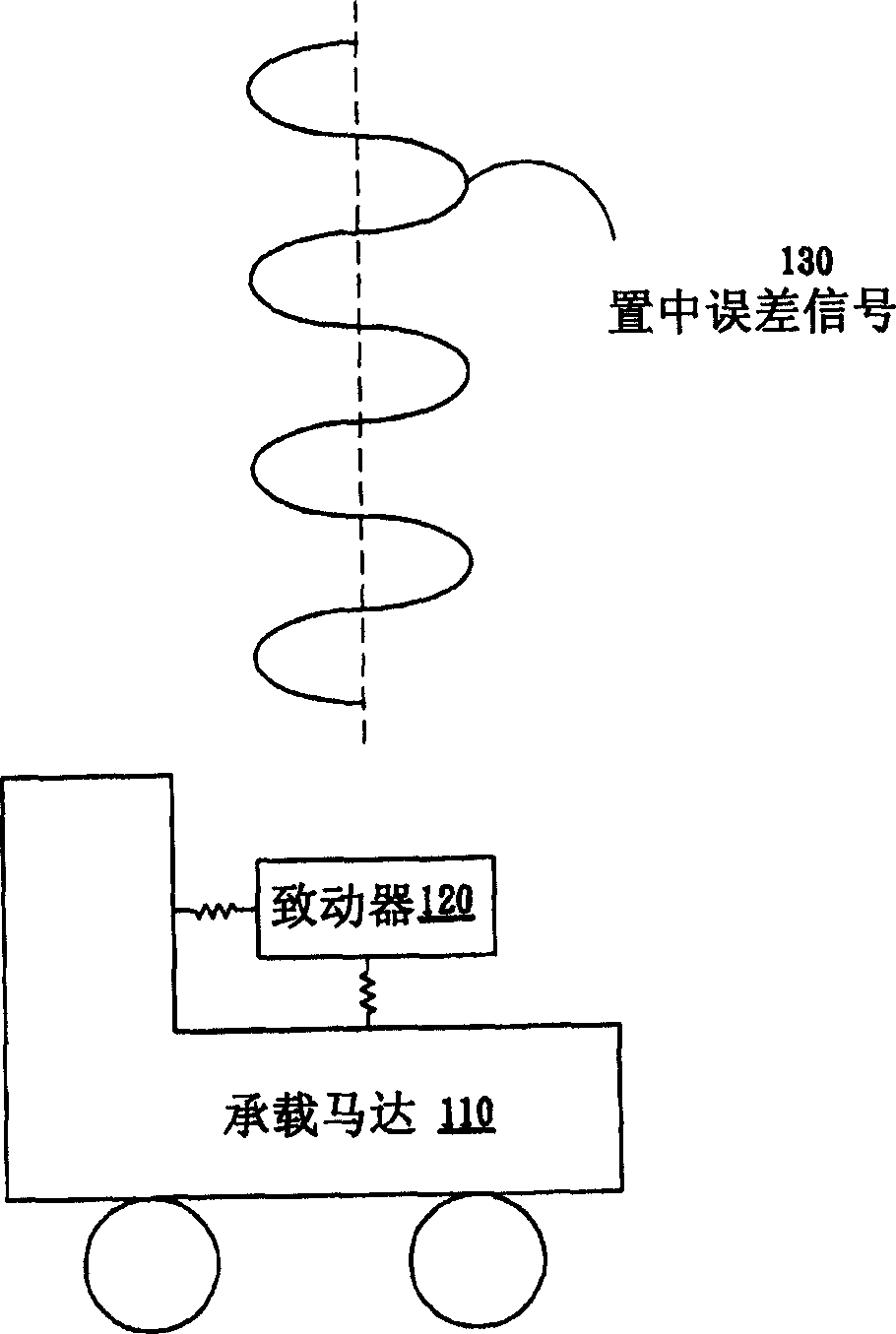

[0031] figure 1 A tracking actuator 120 and a carrier motor 110 are shown in . When reading or writing disc data, a center error signal (CE signal) 130 indicating the movement of the tracking actuator 120 and the carrier motor 110 is generated.

[0032]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com