A female terminal fitting and connector provided therewith

A technology of terminal joints and connectors, which is applied in the direction of connection, two-part connection device, and parts of the connection device, etc., can solve problems such as reducing insertion force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

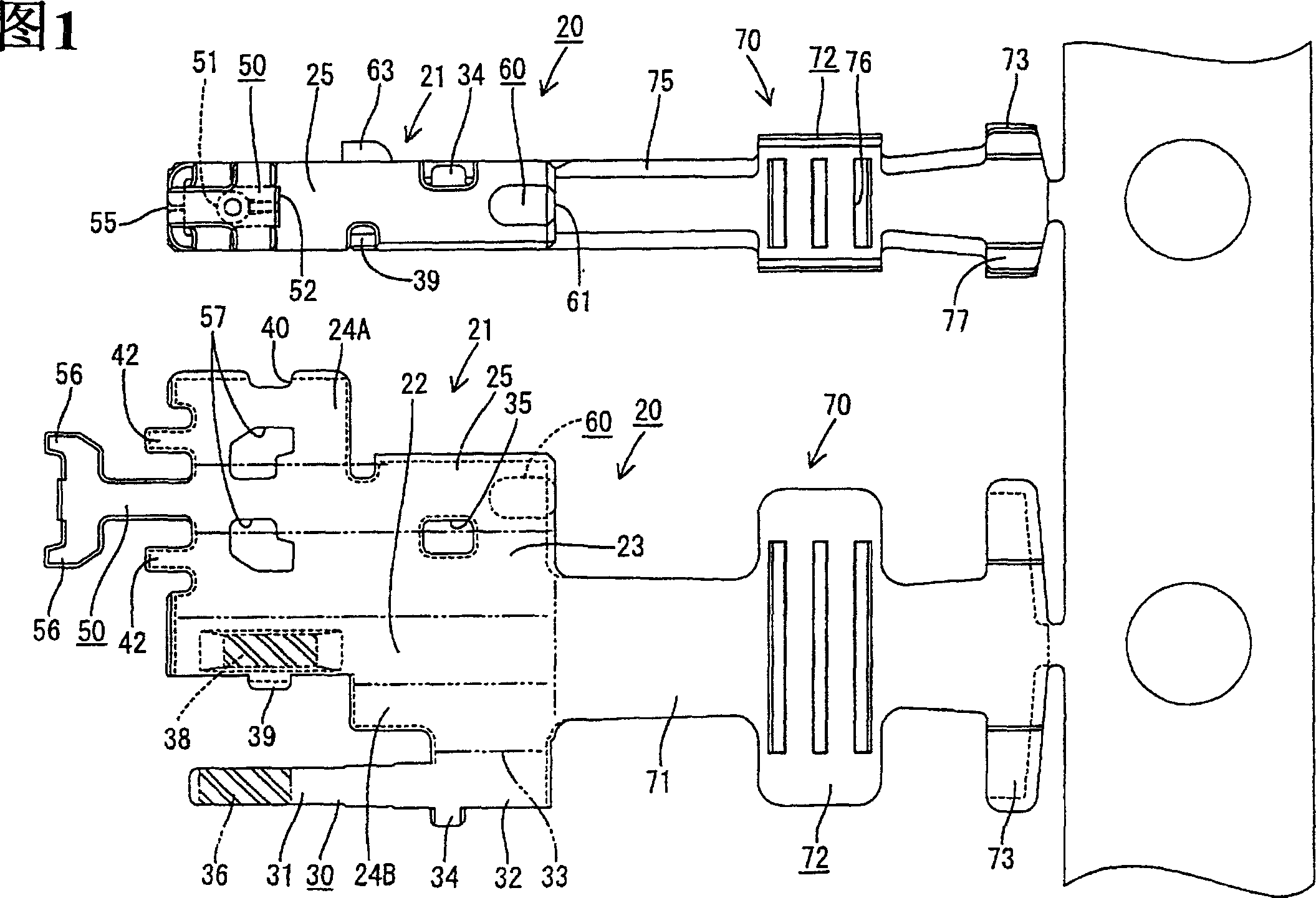

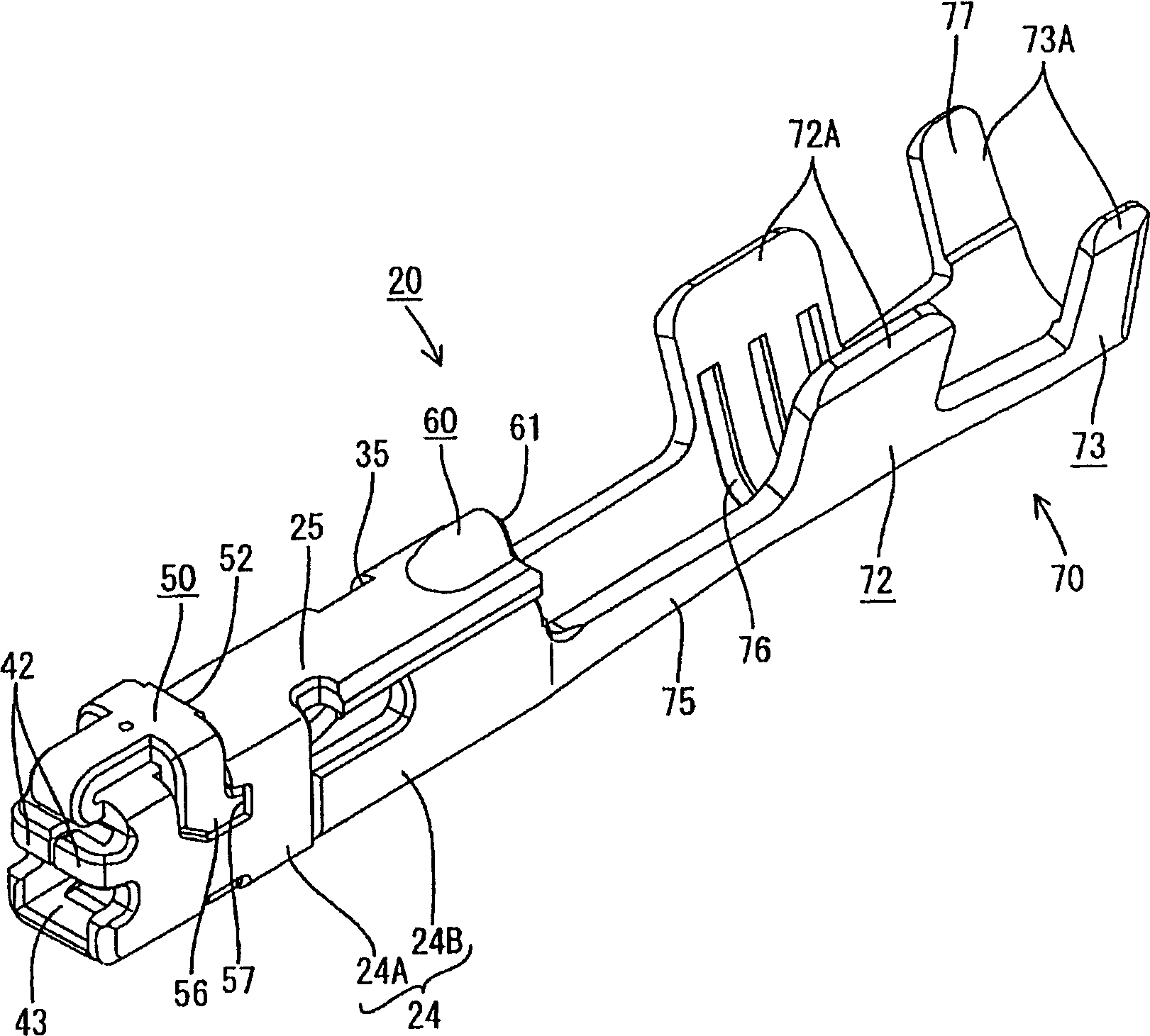

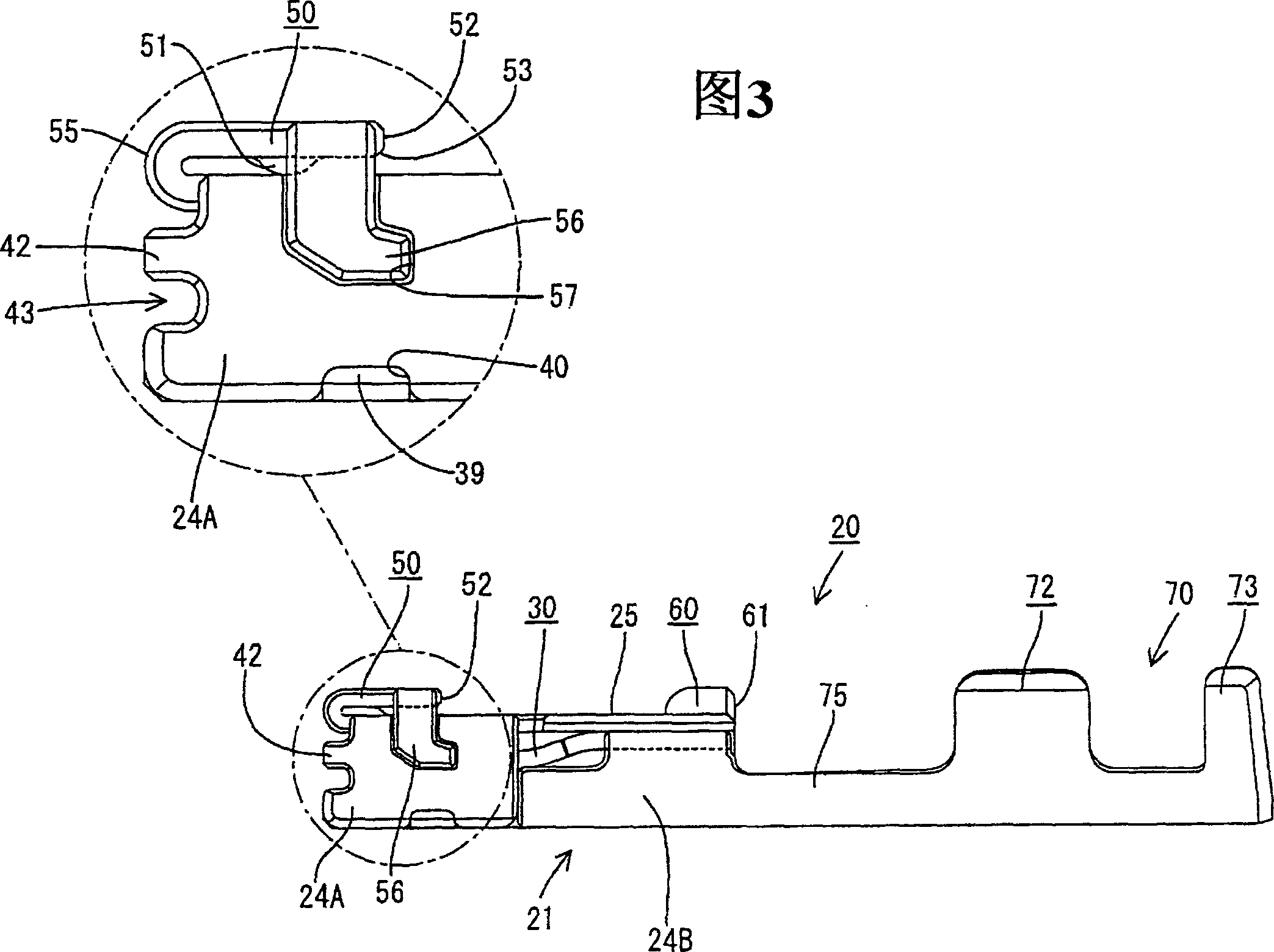

[0043] A preferred embodiment of the present invention will be described below with reference to FIGS. 1 to 11 .

[0044] The female terminal fitting 20 of this embodiment is the upper side and figure 2 Assembled as shown in , preferably by stamping or cutting a conductive (preferably metal) sheet with good electrical conductivity into a formation as shown on the lower side of Figure 1, followed by multiple applications of bending, folding and / or pressing print. In general, the female terminal fitting 20 is such that a body portion 21, preferably substantially in the form of a rectangular tube, is provided before or adjacent to the wire connection portion 70 for fixing to the end of the wire 10, and a mating male terminal fitting Mt (see Figure 11 ) is at least partially inserted into the body portion 21 from the front.

[0045] The female terminal fitting 20 is or will be at least partially housed in the female housing 15 after being connected to the end of the insulated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com