Handle clip and folder comprising the same

A folder and handle technology, applied in folders, printing, binding, etc., can solve problems such as inability to use, unsmooth use, inconvenience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

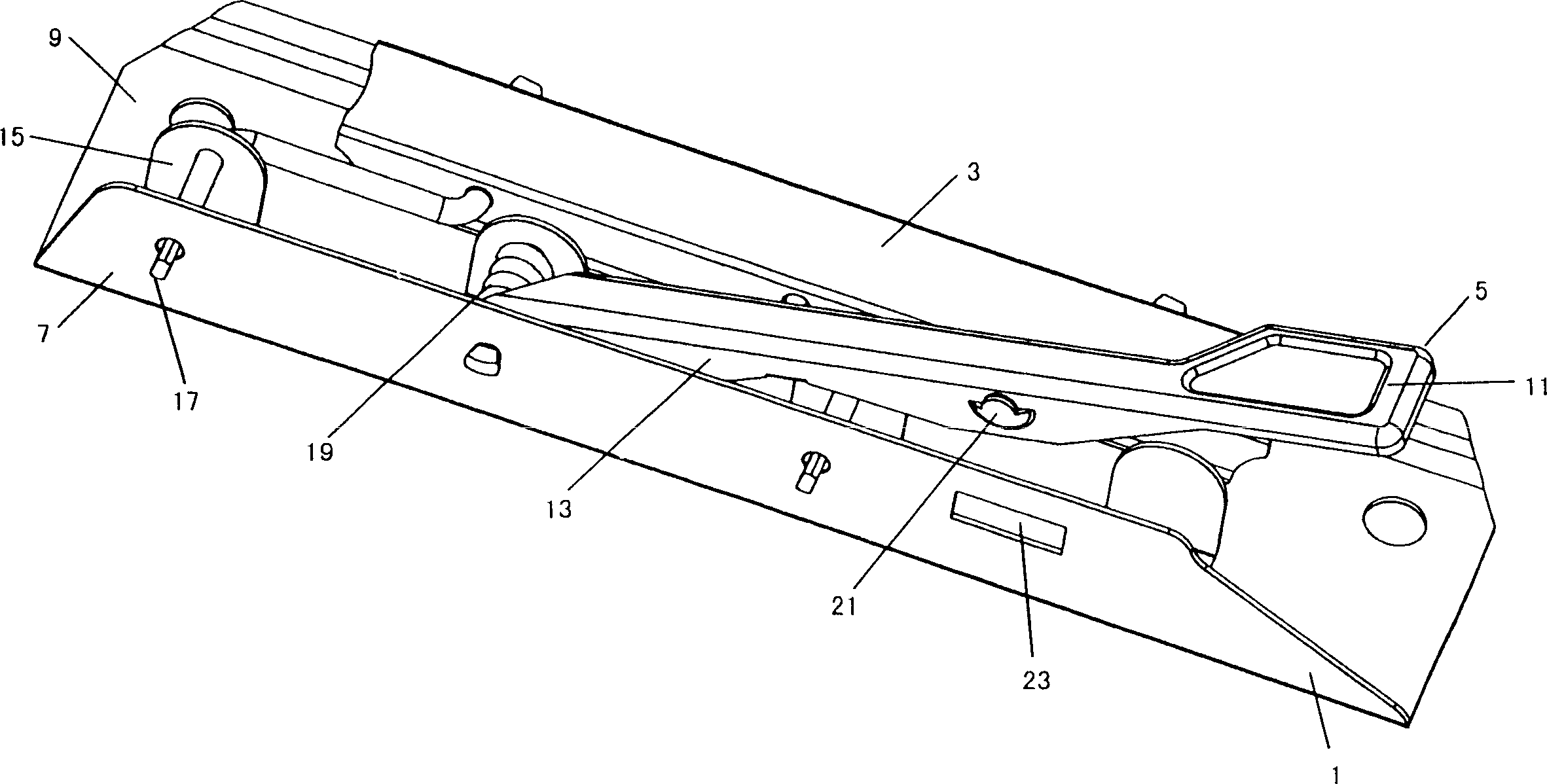

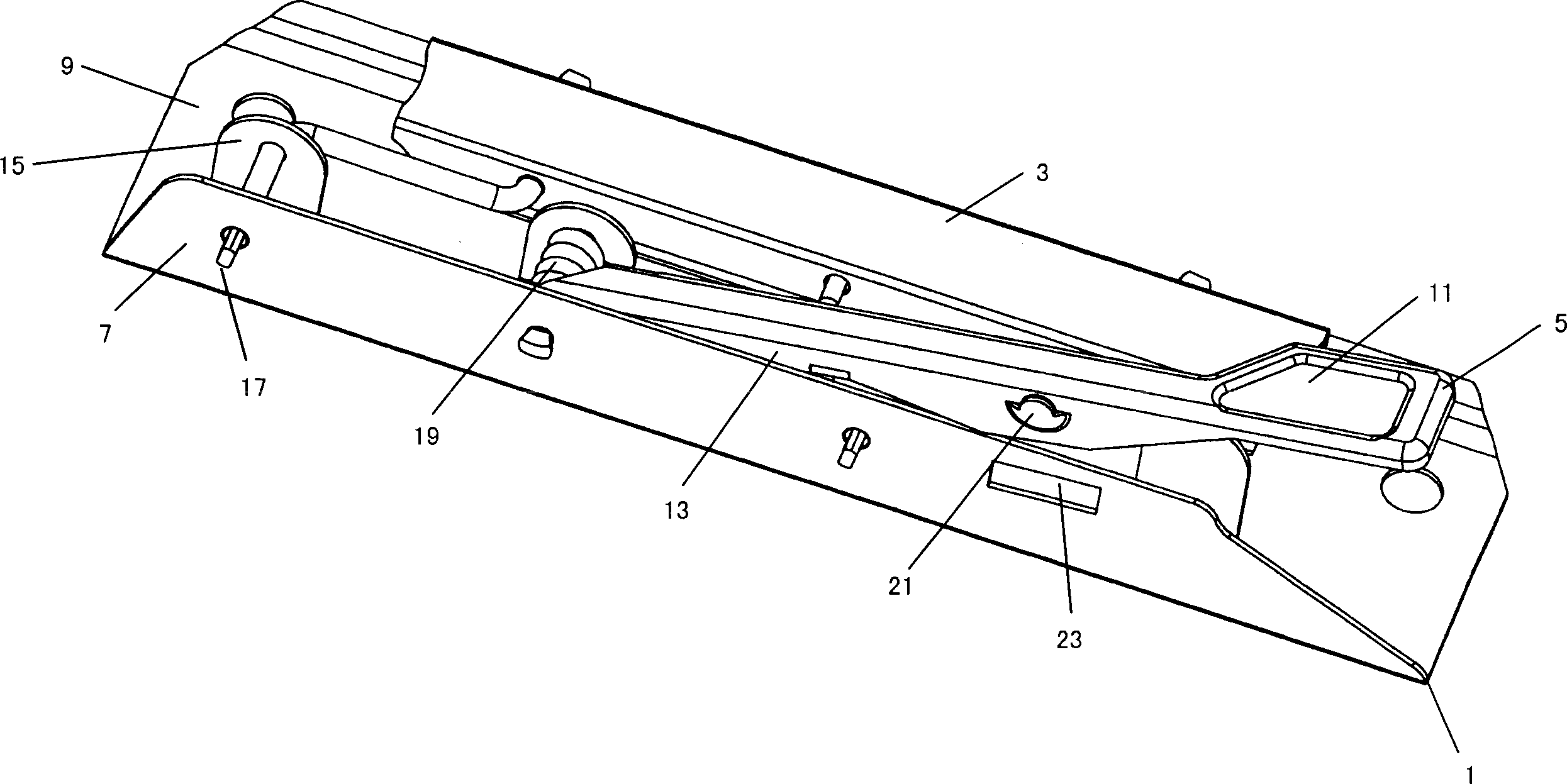

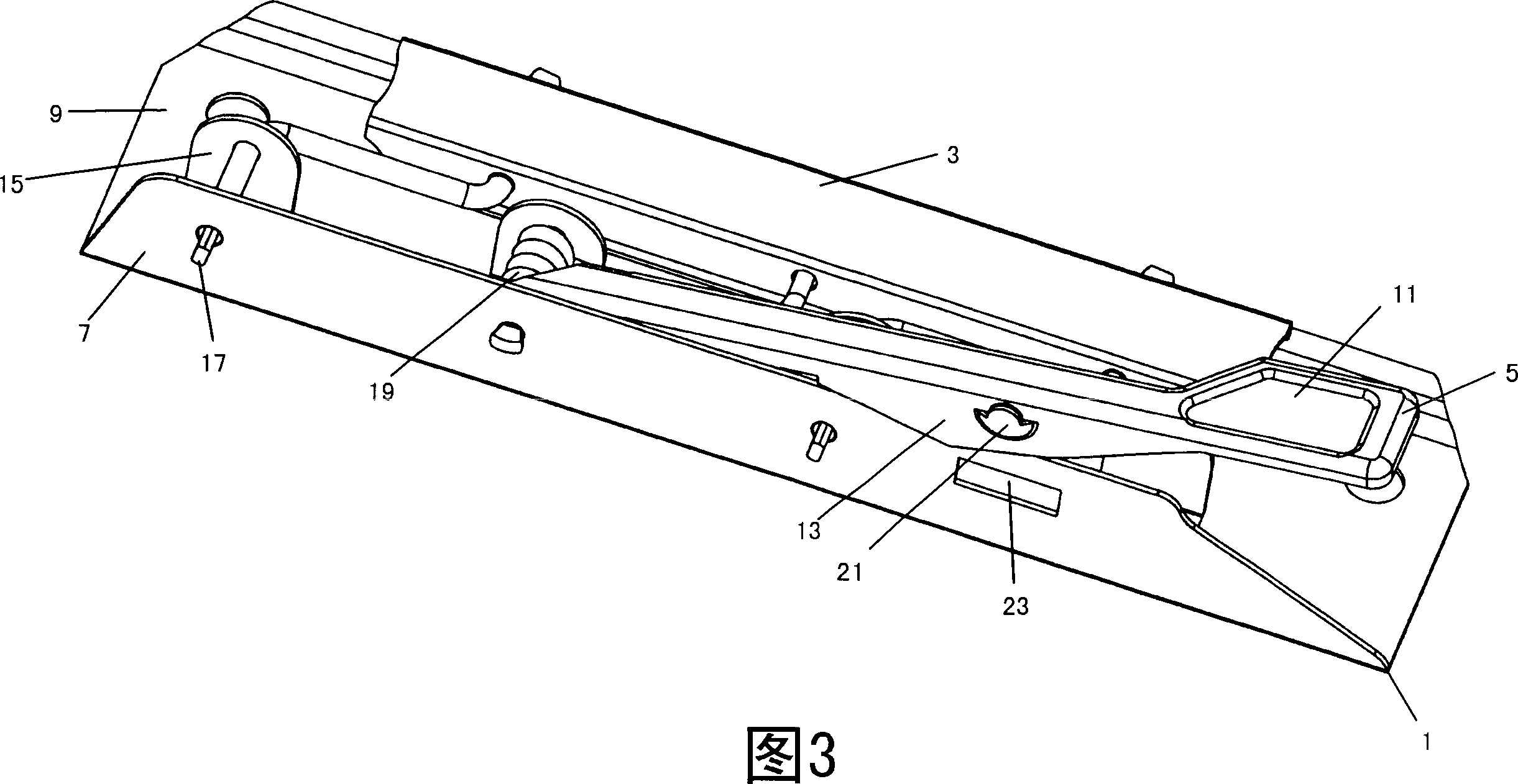

[0024] Such as Figure 4 - As shown in 6 and 11 , the handle clip according to the present invention generally includes a base 1 , a pressing part 3 and a handle 5 . The base 1 is bent at about 90 degrees to form upward standing side walls 7 and a horizontal bottom wall 9 . The pressing part 3 extends in a strip shape. The handle 5 includes a horizontal top wall 11 and a side wall 13 bent downward at about 90 degrees.

[0025] Four protruding walls 15 bent upward at approximately 90 degrees are formed on the bottom wall 9 of the base by stamping, and the number of protruding walls 15 can be more than four or less than four as required. The base 1, pressing part 3 and handle 5 are movably assembled together by means of three pivot shafts 17 and springs 19 supported by holes on the side walls of the base and the protrusion wall 15, so that the handle 5 can be wound around the support spring 19 The pivot shaft 17 is rotatably mounted on the inside of the side wall 7 of the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com