Electric connector

A technology of electrical connectors and electrical connections, applied in connection, fixed connection, circuits, etc., can solve problems such as high generation, accumulated heat, and abnormal operation of the central processing unit 21, so as to improve performance and facilitate heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

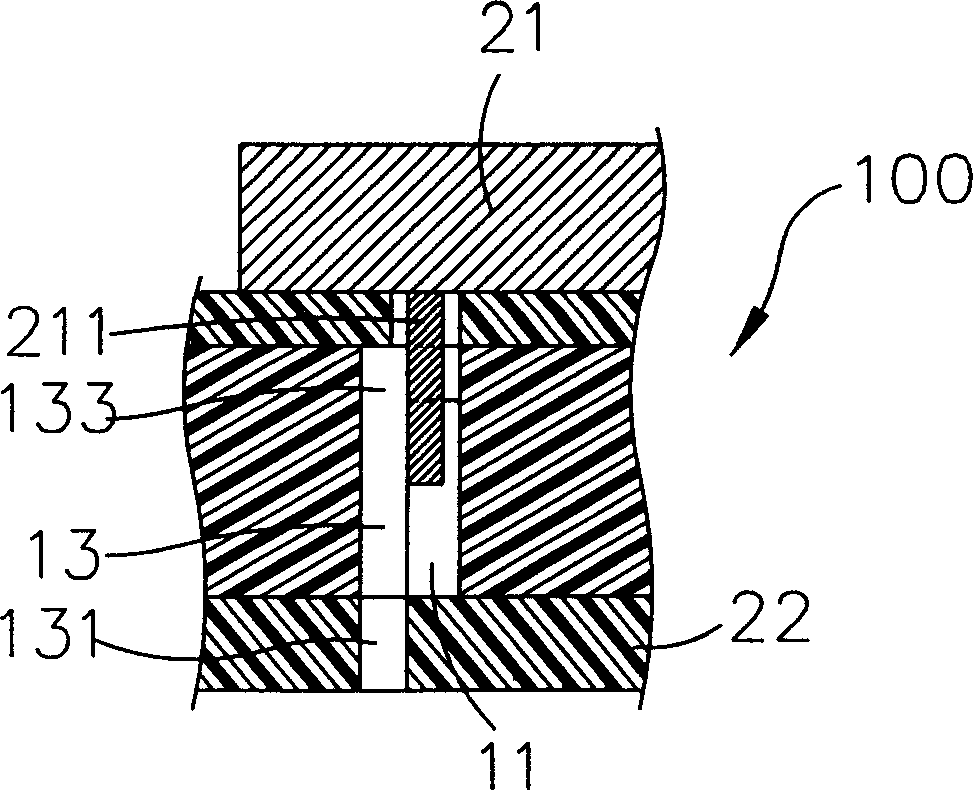

[0022] 4 and 5 are preferred embodiments of the electrical connector of the present invention. The electrical connector 500 of this embodiment includes a base 6 , a plurality of terminals 7 and a protective body 8 .

[0023] The base 6 is a rectangular body, and has a mounting surface 601 and an opposite clamping surface 603. Two upright walls 611 extend vertically from opposite sides of the clamping surface 603. The two upright walls 611 are parallel to each other and Extend in a direction away from the mounting surface 601, and then vertically extend a transverse wall 612 towards each other inwardly. In this embodiment, the two transverse walls 612 are not in contact with each other and are parallel to the clamping surface 603. By The two upright walls 611 and the two transverse walls 612 form an accommodating space 605 on the clamping surface 603 .

[0024] A plurality of first through-holes 606 are penetrated on the base 6, and a second through-hole 607 is respectively pen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com