Steel band reinforced plastic drainpipe and method and apparatus for manufacturing the same

A technology of reinforced plastics and drainage pipes, applied in water supply devices, sewer pipe systems, waterway systems, etc., to achieve the effect of saving raw materials, saving transportation costs, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Step 1 of the method of the present invention includes two ways of one-step compounding and two-step compounding.

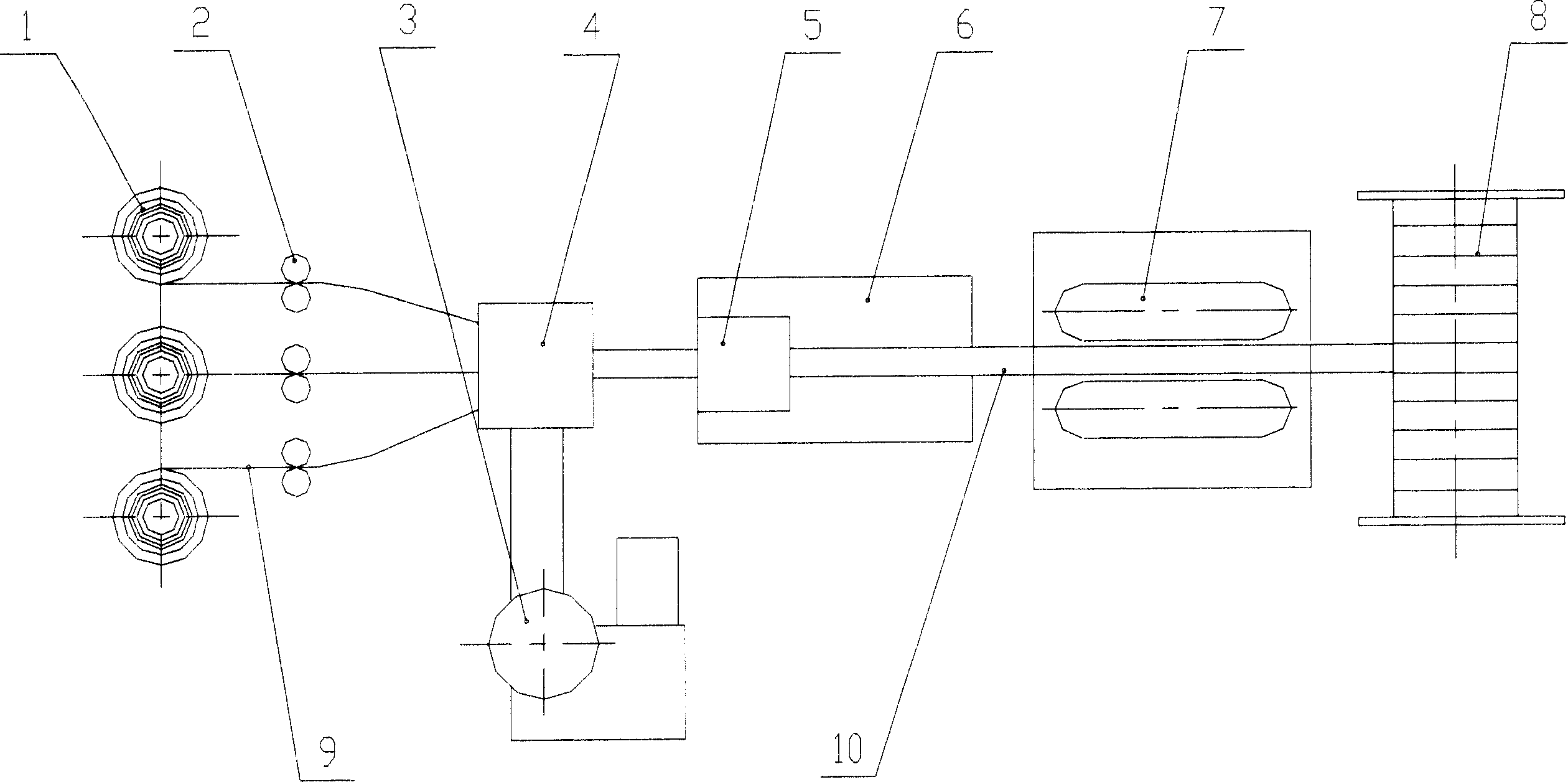

[0019] Combine below figure 1 Describe the one-step composite approach.

[0020] figure 1 It includes steel strip unwinding device 1, guide roller 2, extruder 3, composite machine head 4, calibrator 5, cooling water tank 6, tractor 7, winder 8, steel strip 9, and compound special-shaped strip 10.

[0021] exist figure 1 In the process, the steel strip 9 from the unwinding device 1 is first pulled by the tractor 7, so that the steel strip 9 enters the compound head 4, the key component of extrusion compounding, under the guidance of the guide roller 2, and the compound head 4 and the extruder 3 are connected at right angles, and its internal cavity has a shape corresponding to the compound special-shaped strip 10. When the steel strip 9 passes through the compound head 4, the plastic extruder 3 squeezes molten plastic into the compound head 4. The plast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com