Microchannel plate having microchannels with deep funneled and/or step funneled openings and method of manufacturing same

A micro-channel plate and micro-channel technology, applied in the field of micro-channel plates with micro-channels, can solve the problems of reduced collection efficiency, reduced signal-to-noise ratio, reduced performance of image intensifier tubes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

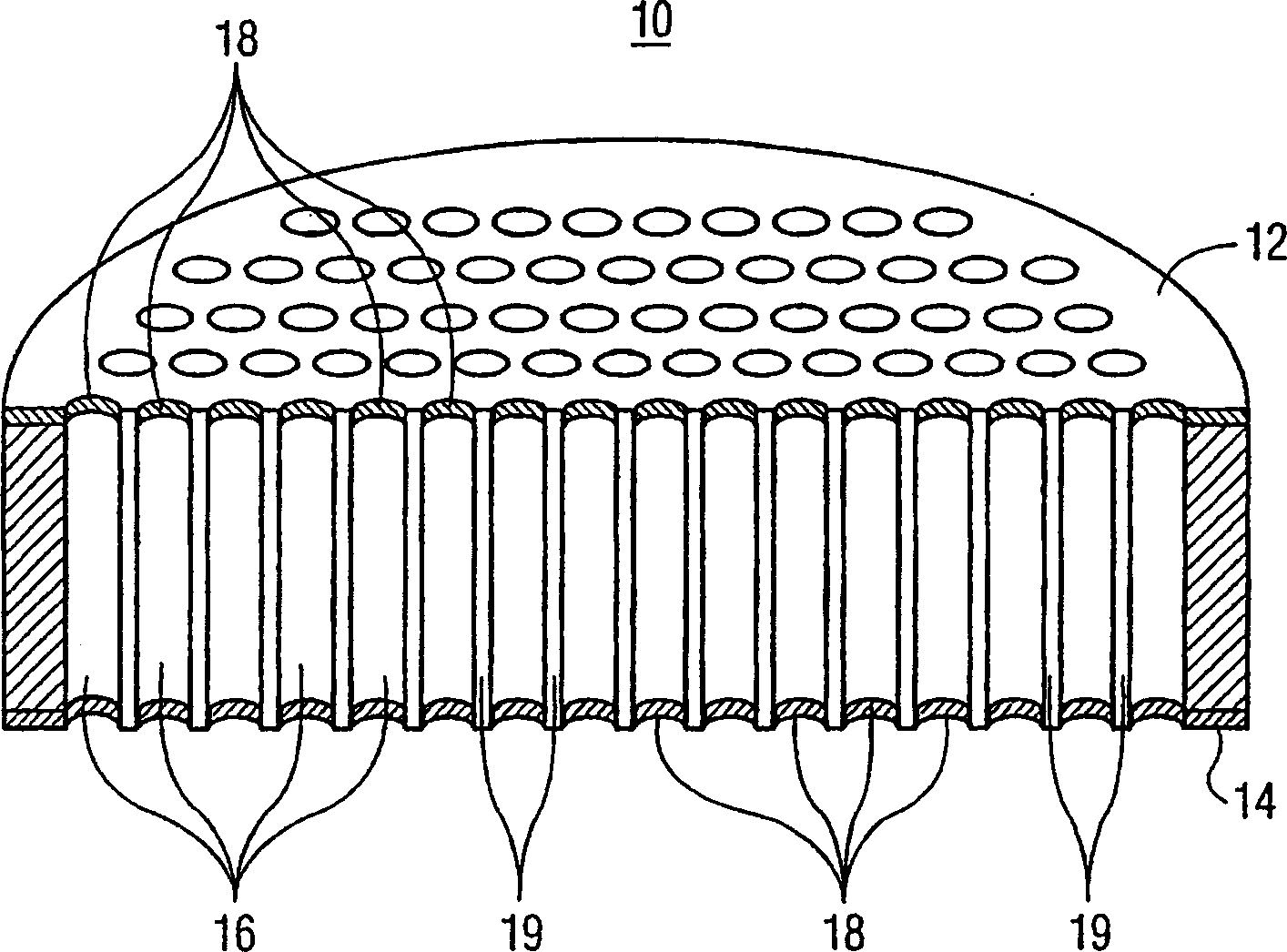

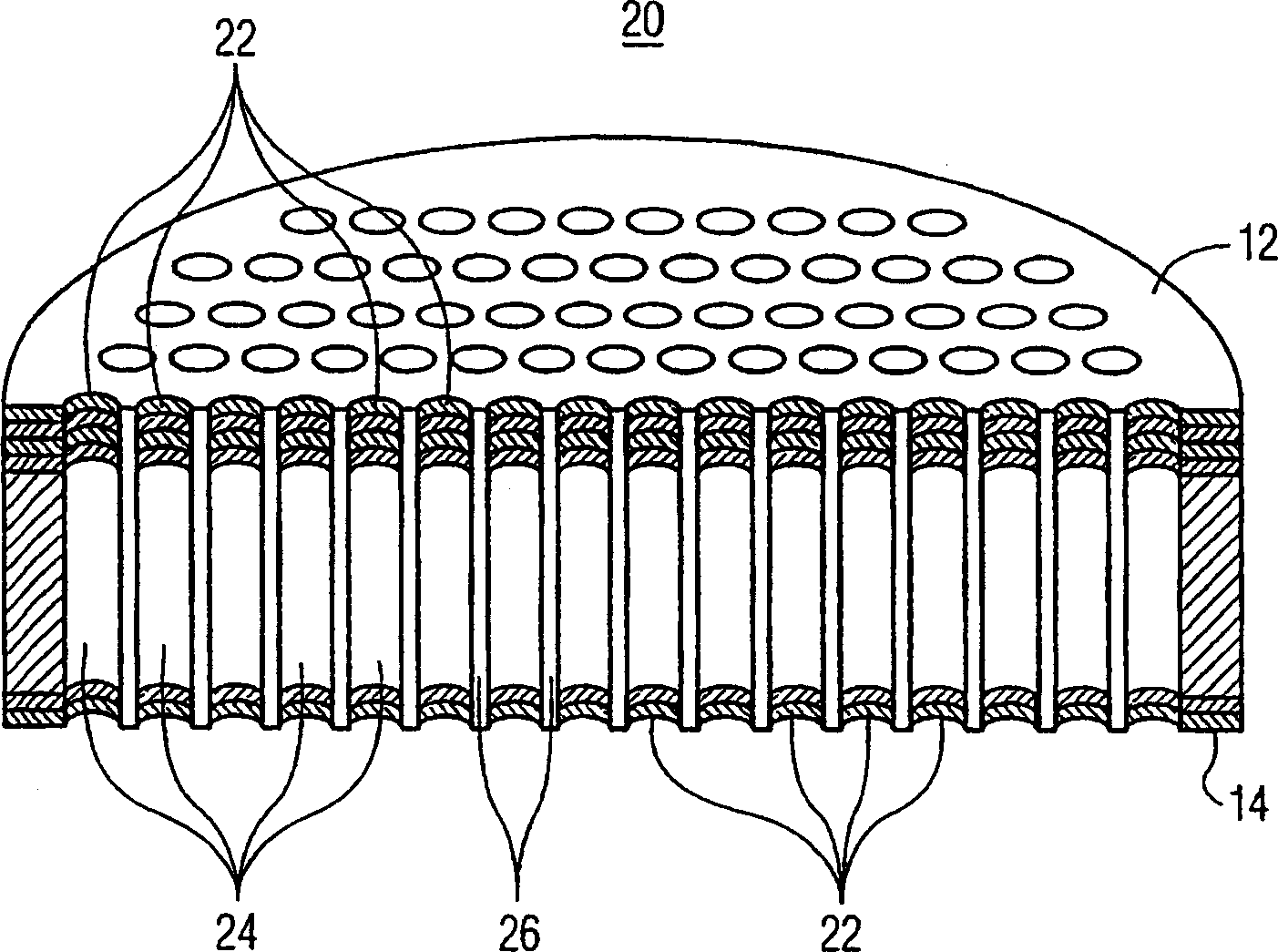

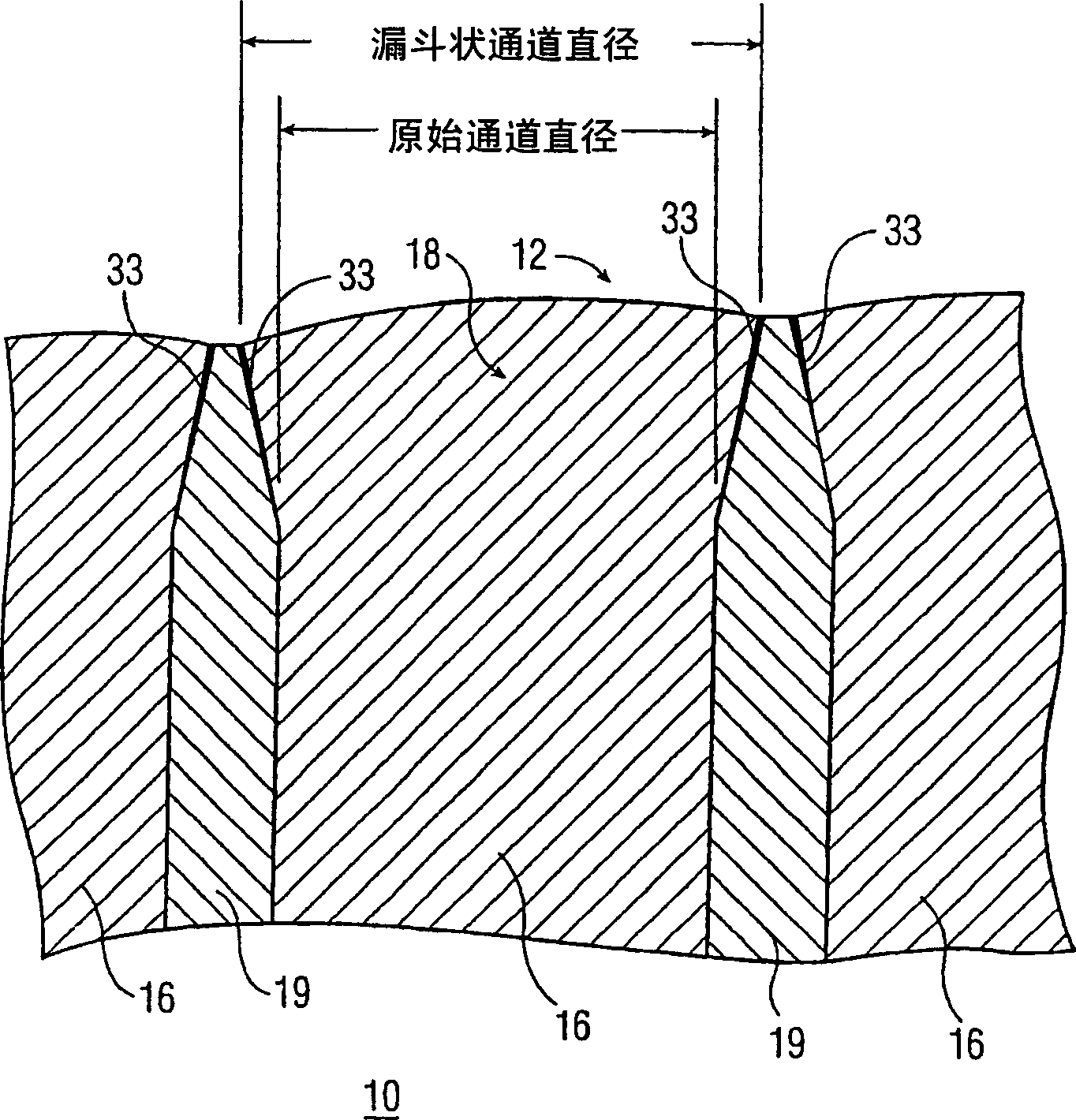

[0029] In accordance with the present invention, a microchannel plate (MCP) with deep funnel-shaped openings and / or stepped funnel-shaped openings overcomes the drawbacks due to metallization of exposed microchannels on the input side or output side. By moving the funnel deeper into the MCP microchannel (or further away from the input / output side), the performance of the MCP is improved without performance degradation due to any metallization process. Incident electrons are less prone to hitting metal coatings located in deep funnel channels, as they may be located in perfectly straight channels of the same diameter.

[0030] Additionally, while deep funnel-shaped channels have a wider diameter than non-funnel-shaped channels or substantially funnel-shaped channels (basic funnel-shaped channels as disclosed in US Pat. 90% of its length) with sufficient wall thickness and provide sufficient strength and stiffness to the MCP.

[0031] refer to Figure 1B , which shows a cross-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com