Measurer and pip displacement processing program

A technology for measuring instruments and marking points, which is applied in the field of electronic total stations, and can solve problems such as troubles, inability to set up laser plumb instruments, and reduced accuracy of shifting points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

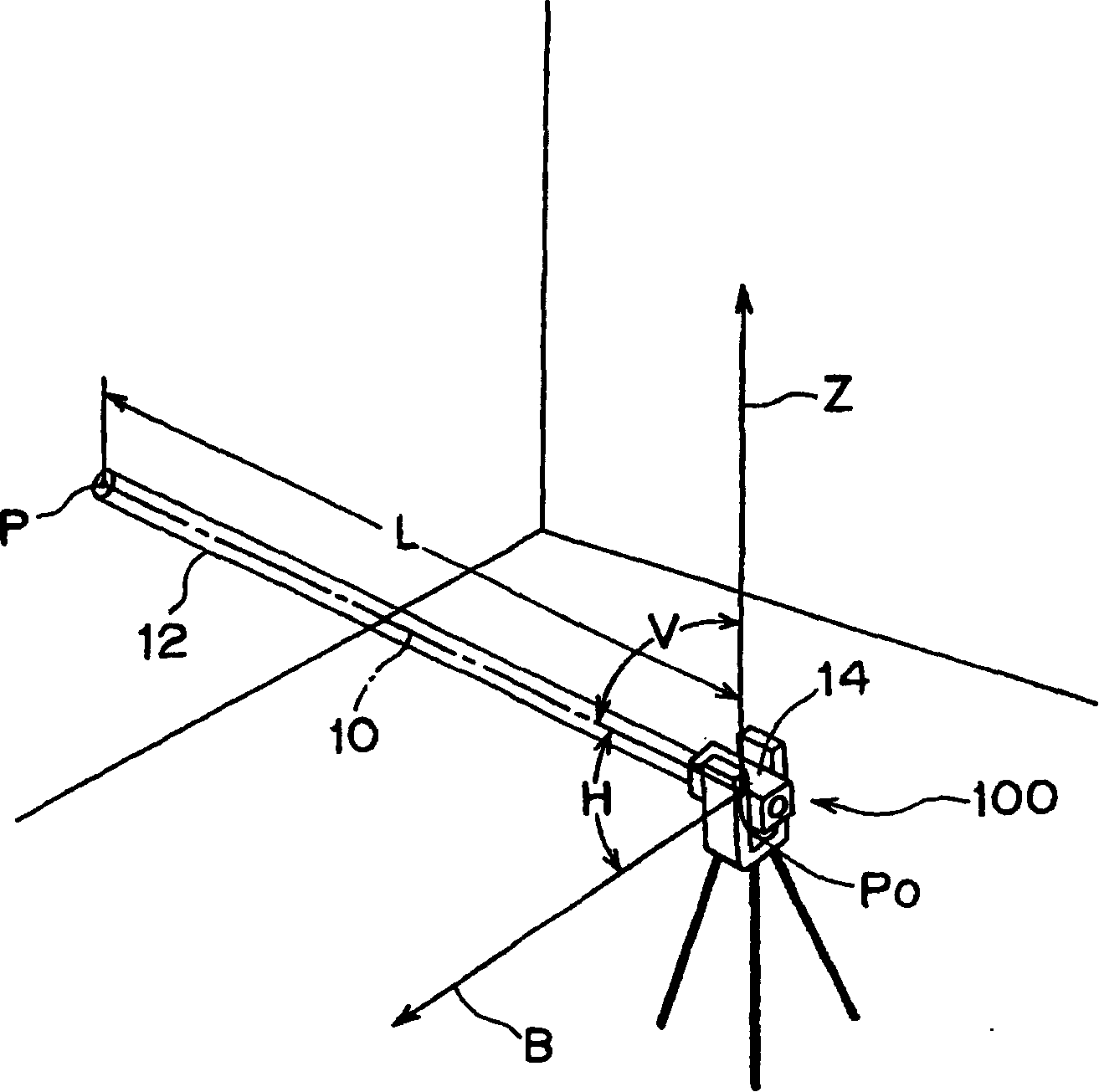

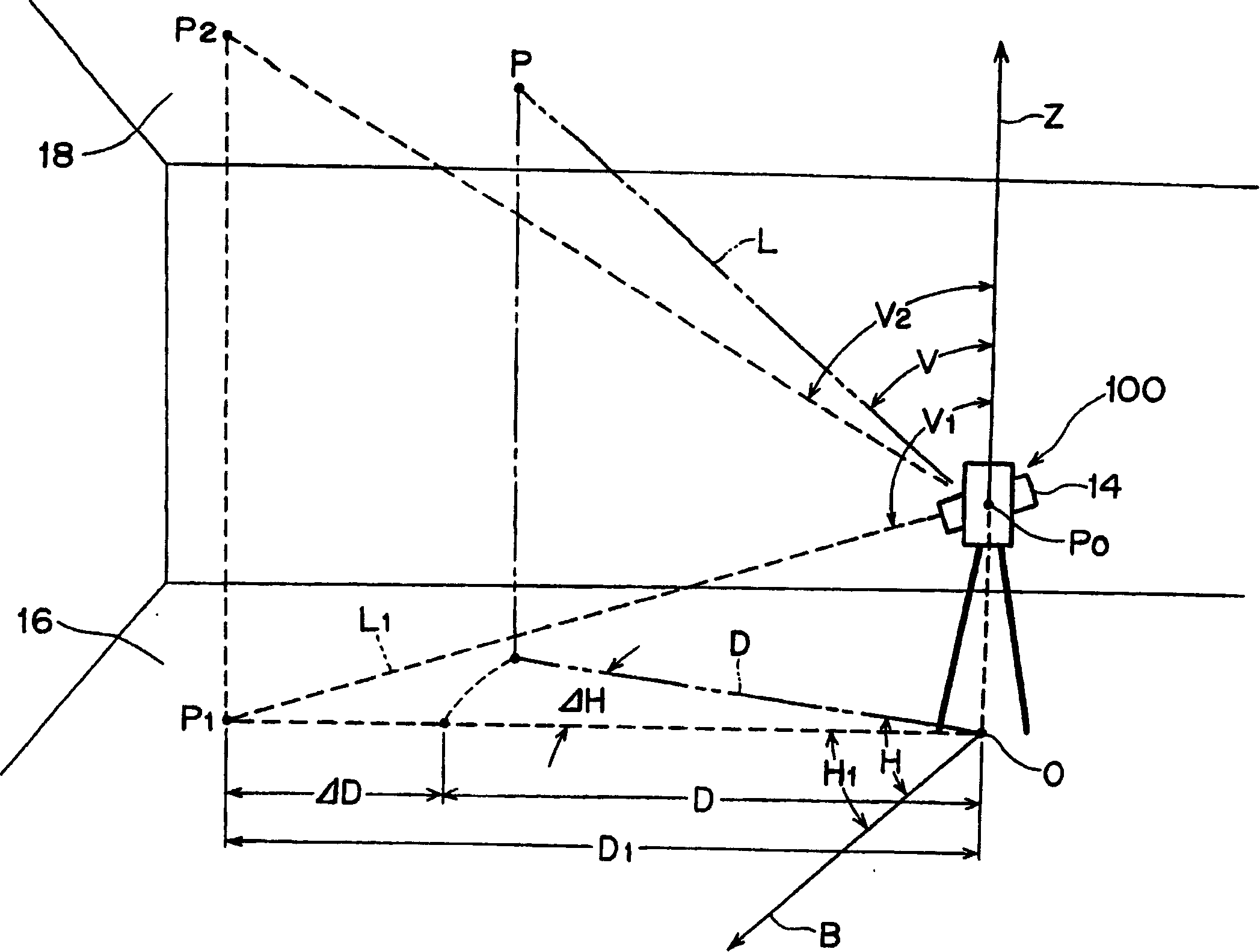

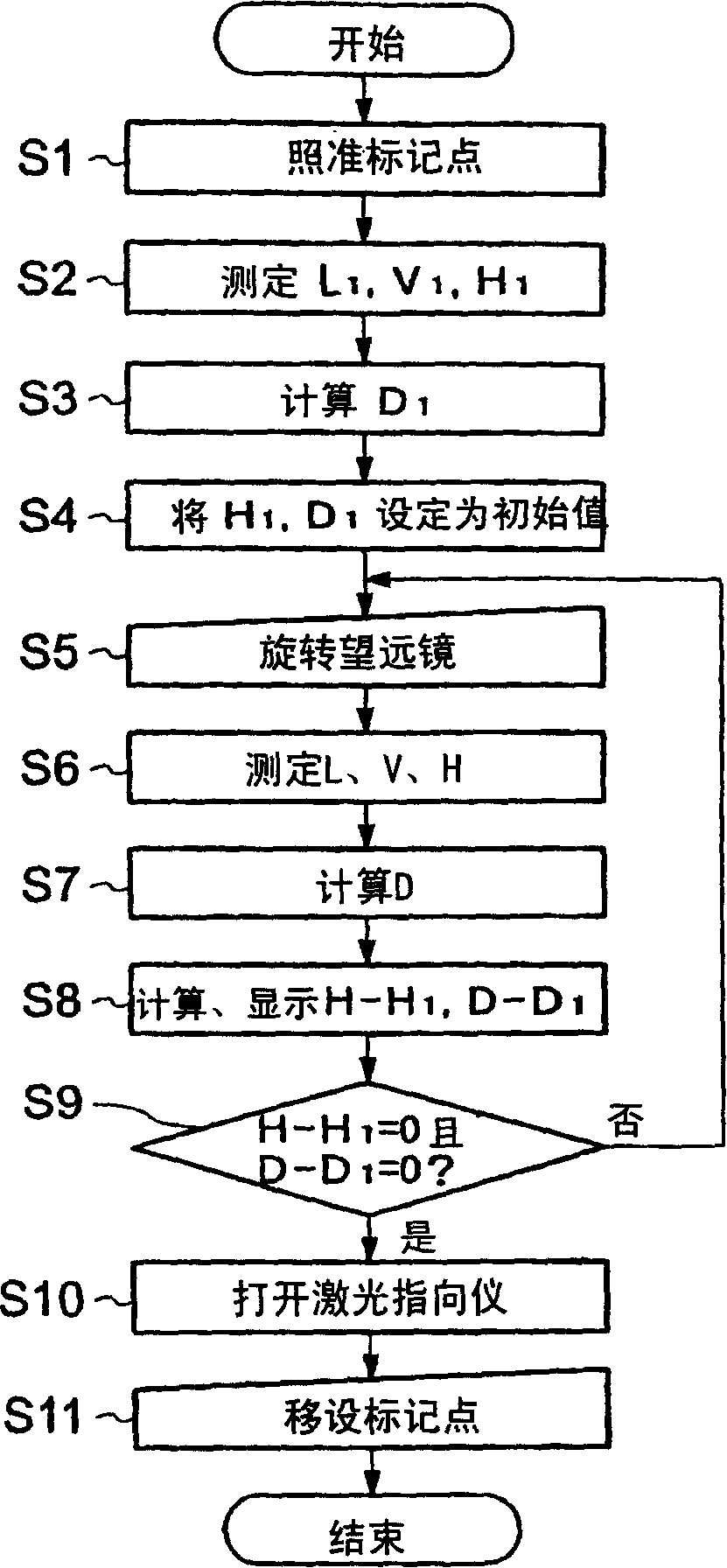

[0033] The present invention uses one measuring instrument including a laser pointer that emits visible laser light coaxially with the collimating axis, and it is possible to set a floor mark, transfer a floor mark to a ceiling, and the like without moving the measuring instrument. Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings.

[0034] figure 1 It is a figure explaining the outline|summary of the measuring instrument of one embodiment of this invention. figure 2 It is a figure explaining how to transfer the ground mark to the ceiling using this measuring instrument. image 3 It is a flowchart explaining the procedure for transferring a marker point to a ceiling using this measuring instrument. Fig. 4 is a diagram explaining a method of relocating a ground mark on the ground using the measuring instrument. Figure 5 It is a flowchart explaining a marker point setting procedure for moving a ground mark...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com