Heat sink

A heat dissipation device and fan frame technology, which is applied to pump devices, parts of pumping devices for elastic fluids, non-variable pumps, etc., can solve the problem that the fluid performance of the blower has no substantial effect, and the ribs cannot provide flow guide Problems such as function or anti-backflow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

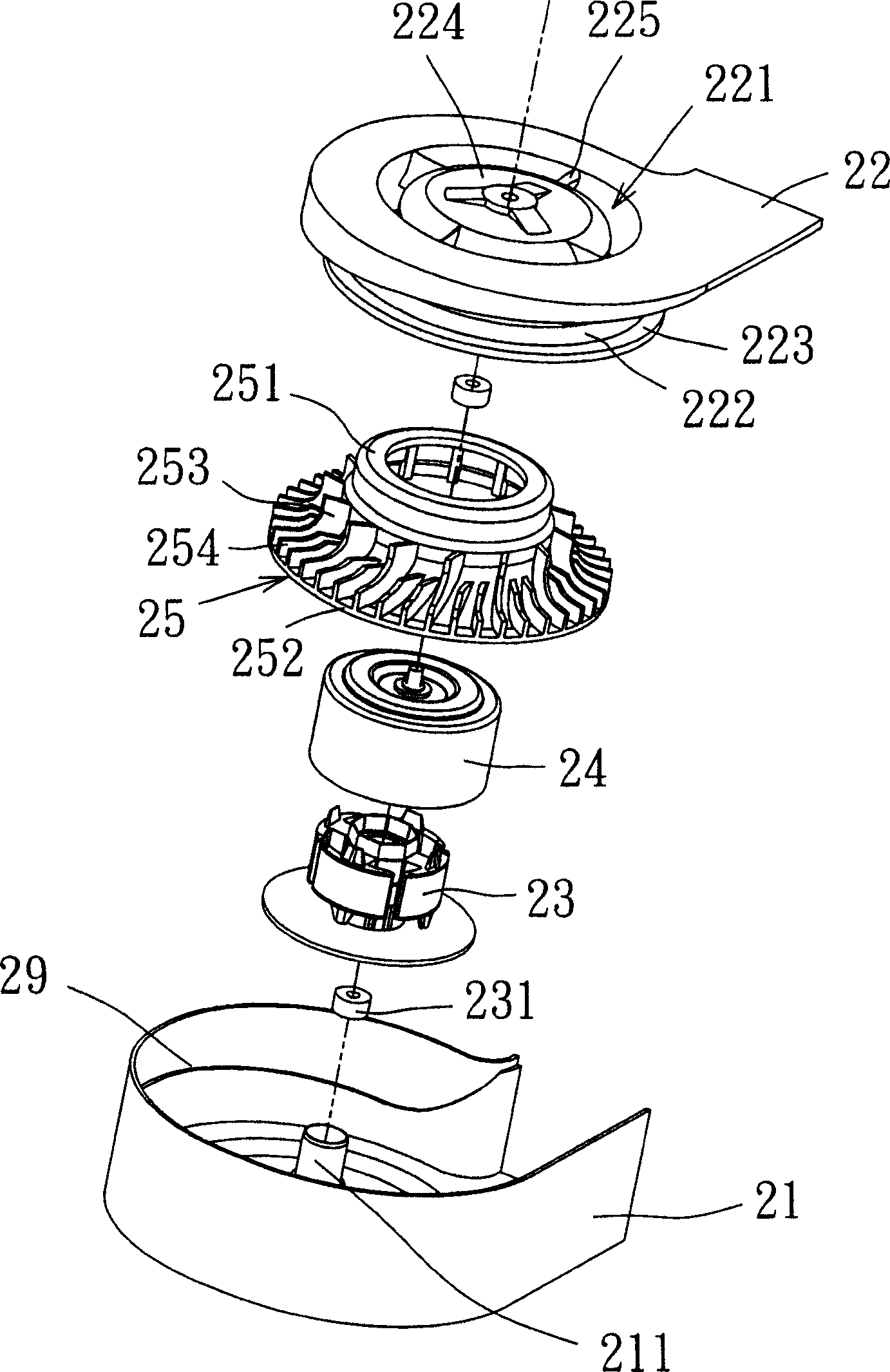

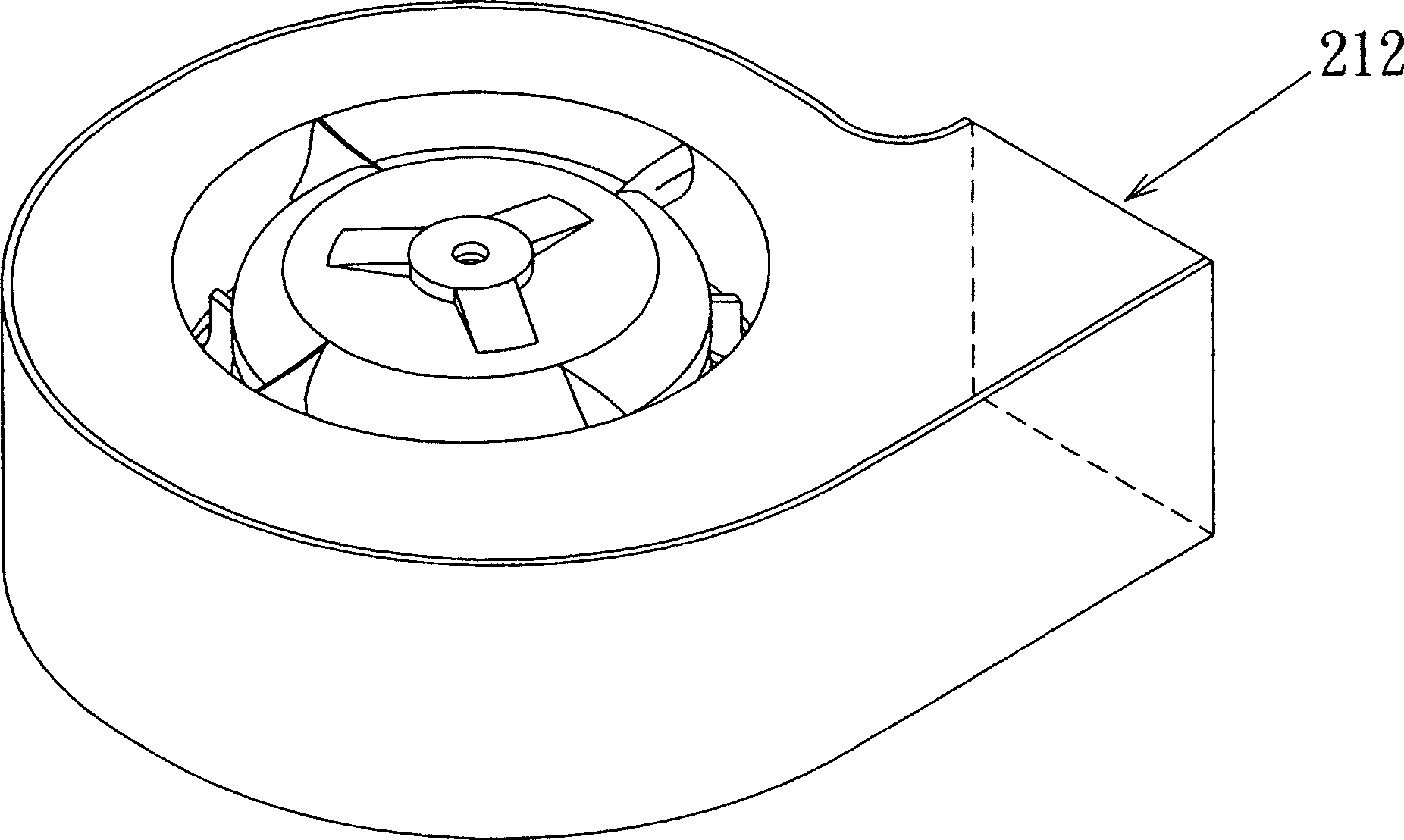

[0029] see Figure 2A to Figure 2C , which shows the first preferred embodiment of the heat sink of the present invention. In this embodiment, a centrifugal fan is taken as an example, but the design method can also be applied to an axial fan. The centrifugal fan is a one-way blower, which mainly includes a first frame 21 , a second frame 22 , a driving device 23 , an iron shell 24 and a rotor blade 25 . The first frame 21 has a socket seat 211 on which the driving device 23 can be placed, and a bearing 231 is placed in the socket seat 211 to support the rotating shaft 27 of the rotor blade portion 25 . The second frame 22 has an air inlet 221 and a wall 222 extending downward from the inner edge of the air inlet. When the second frame 22 is combined with the first frame 21, the second frame 22 The space formed after being combined with the first frame 21 is separated to define an air collecting channel 26 and a space for accommodating the rotor blade 25 , and also forms an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com