Backlight module

A technology of backlight module and light guide plate, applied in optics, nonlinear optics, instruments, etc., can solve the problems of high manufacturing difficulty, uneven brightness, and high cost, achieve uniform brightness, improve brightness uniformity, reduce manufacturing costs and The effect of making difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

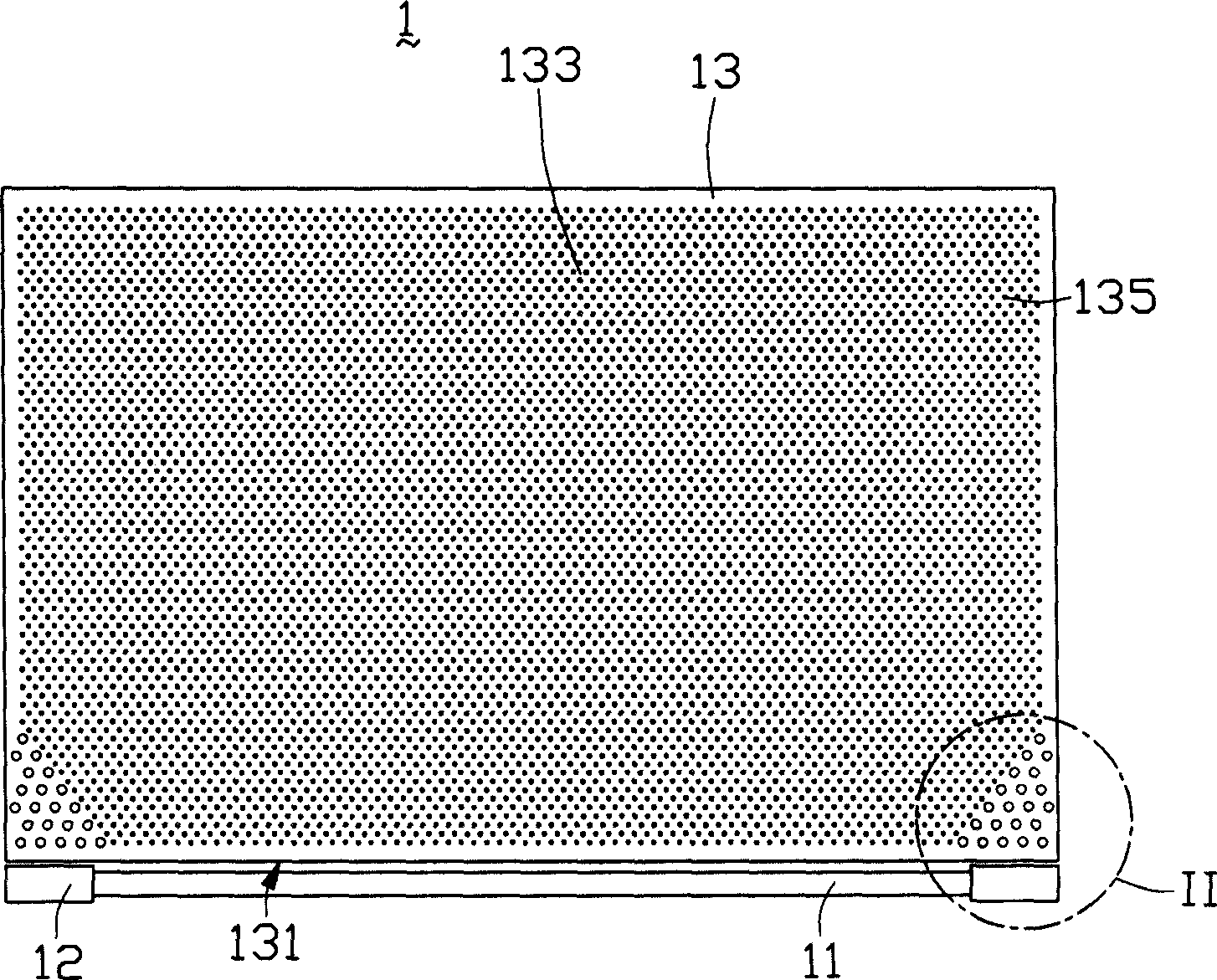

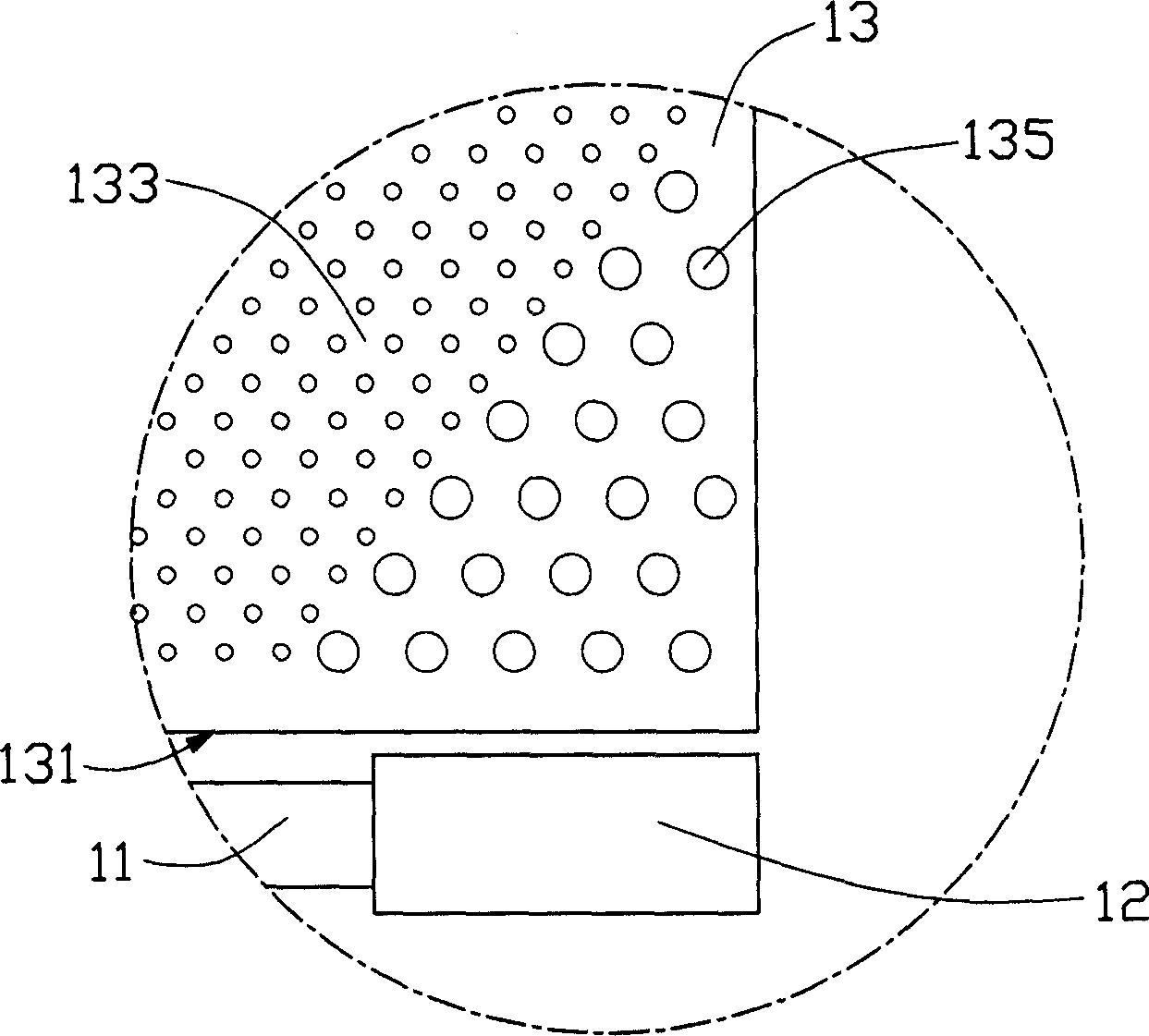

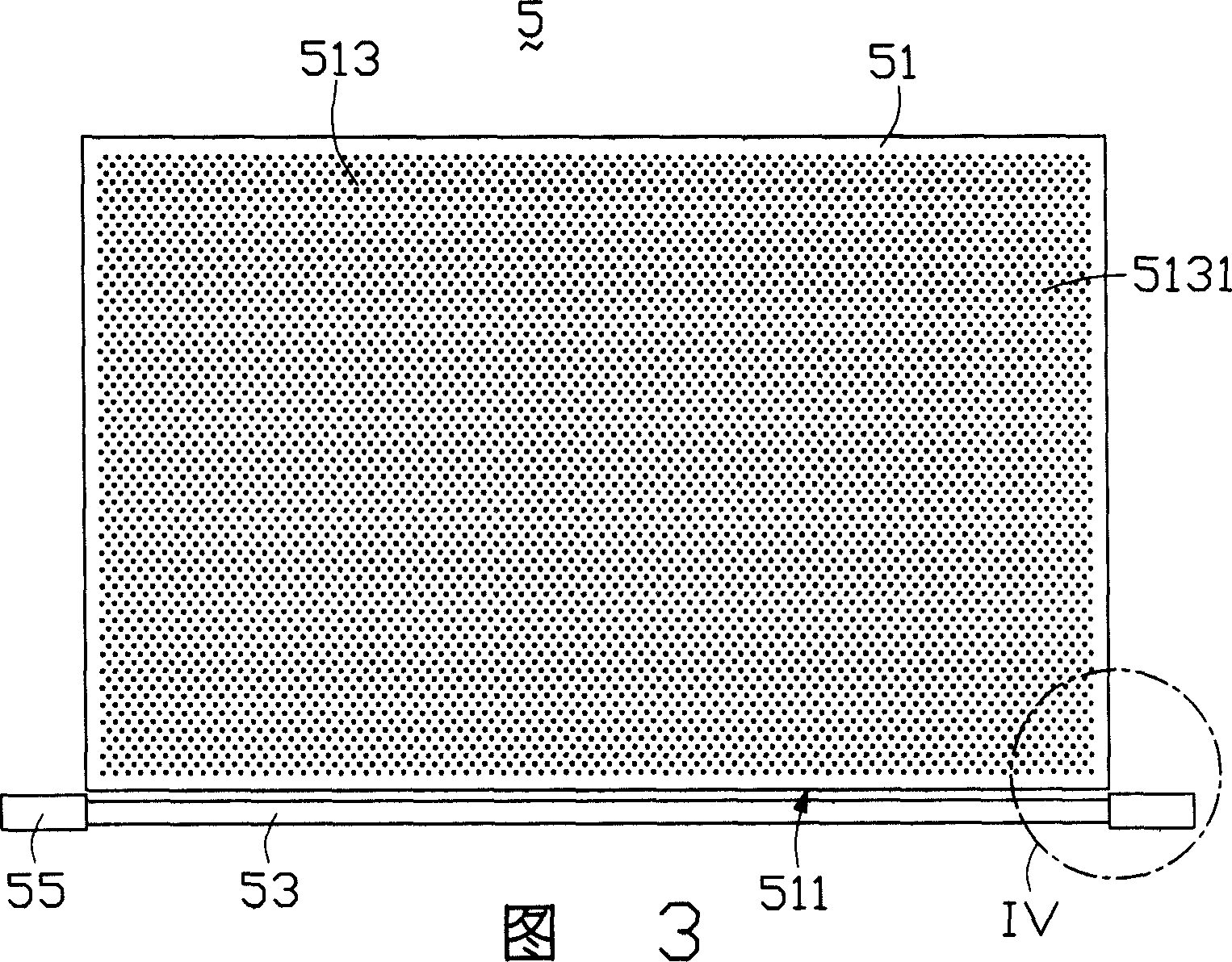

[0018] See Figure 3 and Figure 4 , is a plan view and a partially enlarged view of the first embodiment of the backlight module of the present invention. The backlight module 5 of the first embodiment includes a light guide plate 51 and a light tube 53 . Both ends of the lamp tube 53 are provided with power connection portions 55 for connecting to a power source. The light guide plate 51 is square in shape and includes a light incident surface 511 , a light exit surface 513 and a bottom surface (not shown) opposite to the light exit surface 513 . The surface of the light-emitting surface 511 of the light guide plate 51 is provided with grid dots 5131 for diffusing light beams, and the grid dots 5131 are evenly divided into the light-emitting surface 513 of the light guide plate 51 .

[0019] The light tube 53 is disposed on the light incident surface 511 side of the light guide plate 51 to provide light beams for the light guide plate 51 . Two ends of the lamp tube 53 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com