Method for monitoring blockage status of mechanical filter

A mechanical filter and pressure value technology, applied in chemical instruments and methods, filtration separation, separation methods, etc., can solve problems such as difficult observation and no mechanical filter found

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is further described below.

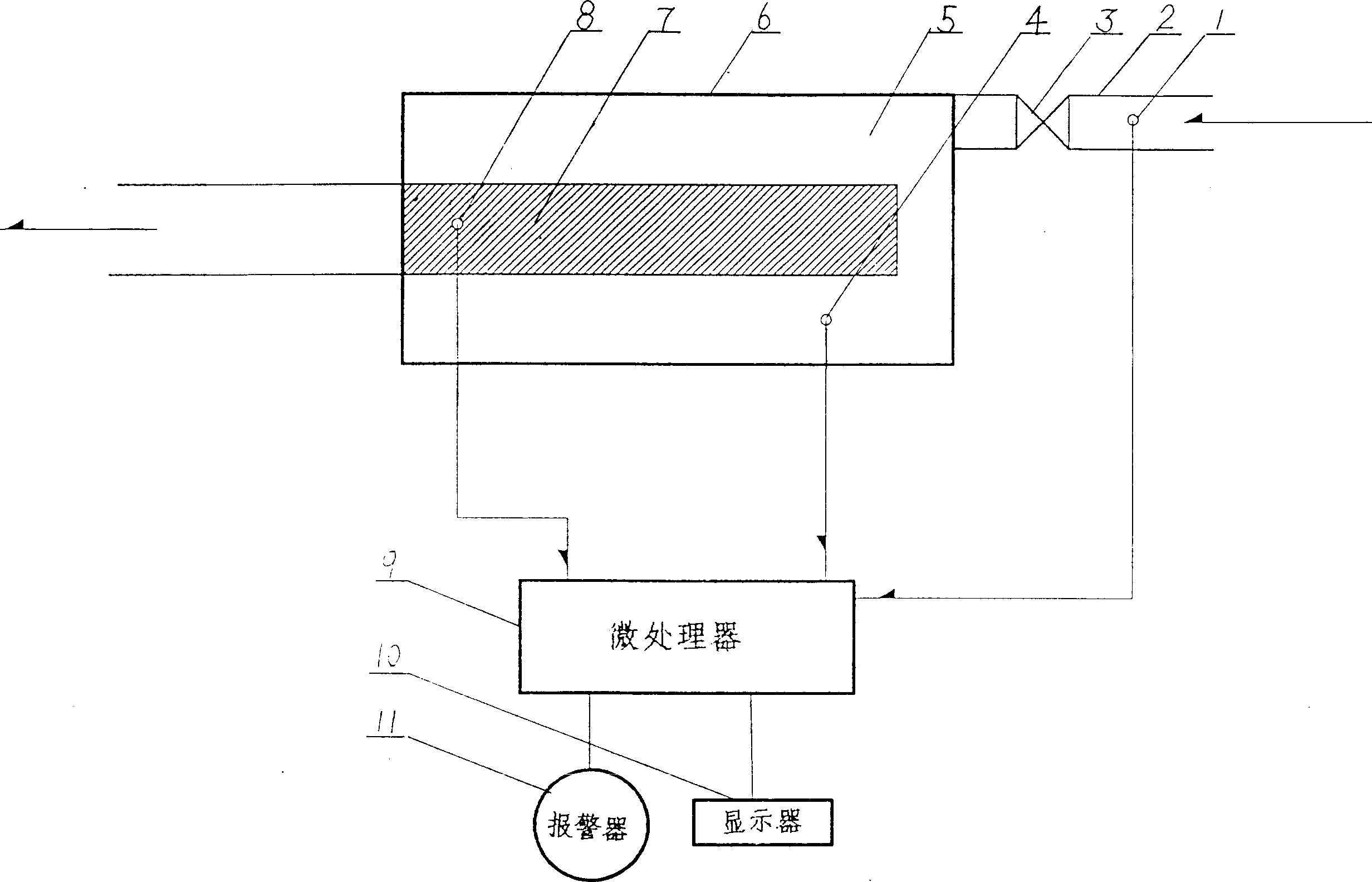

[0013] The measurement of the maximum dynamic pressure value, the static pressure value, the pressure value of the liquid inlet chamber of the mechanical filter, and the pressure value of the liquid outlet chamber of the mechanical filter is completed by a pressure sensor.

[0014] The determination of the complete blockage resistance value, actual resistance value, blockage degree value and blockage situation is completed by the microprocessor.

[0015] The working process of any mechanical filter can be simply divided into three parts: before filtration, during filtration (liquid passes through the filter medium), and after filtration. During the working process, the pressure change before and after filtration has a corresponding relationship with the degree of clogging.

[0016] When the liquid inlet valve is closed and the mechanical filter is not working, the pressure in the liquid inlet pipe is the maximum press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com