Device for measuring slurry spraying intensity of wet desulfurization tower, and measuring method

A technology of wet desulfurization and tower slurry, applied in the direction of measuring devices, separation methods, chemical instruments and methods, etc., can solve problems such as low visibility, high cost, and unrealistic configuration of flowmeters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

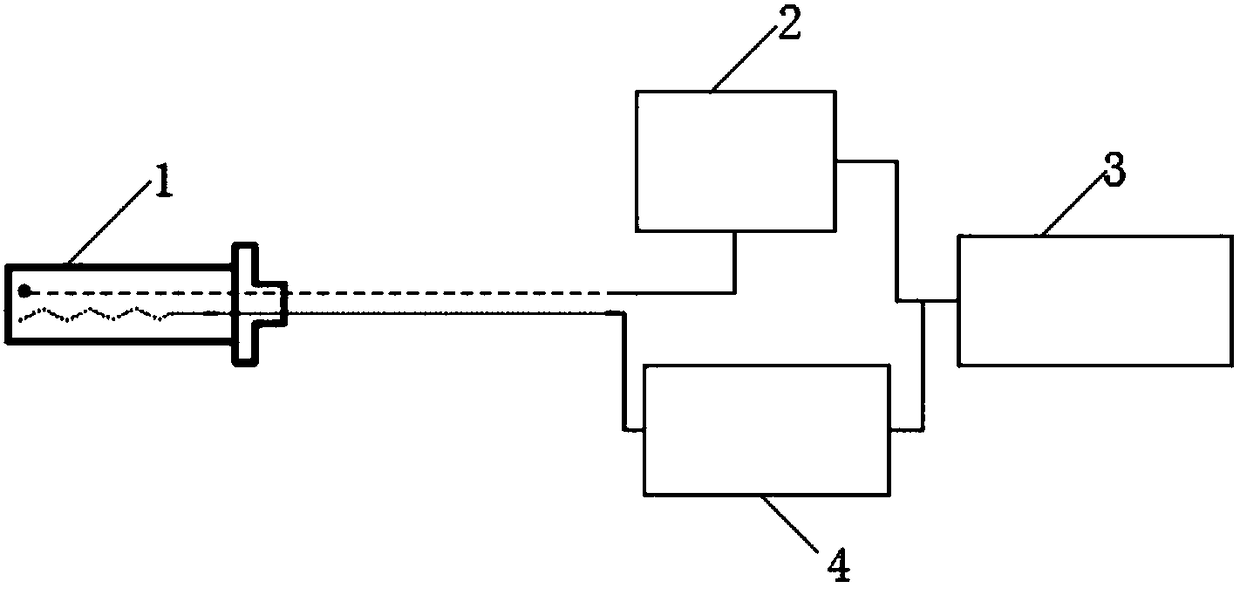

[0034] Such as Figure 1-6 As shown, what is described in the embodiment of the present invention is a device for measuring the spray intensity of slurry in a wet desulfurization tower, which includes:

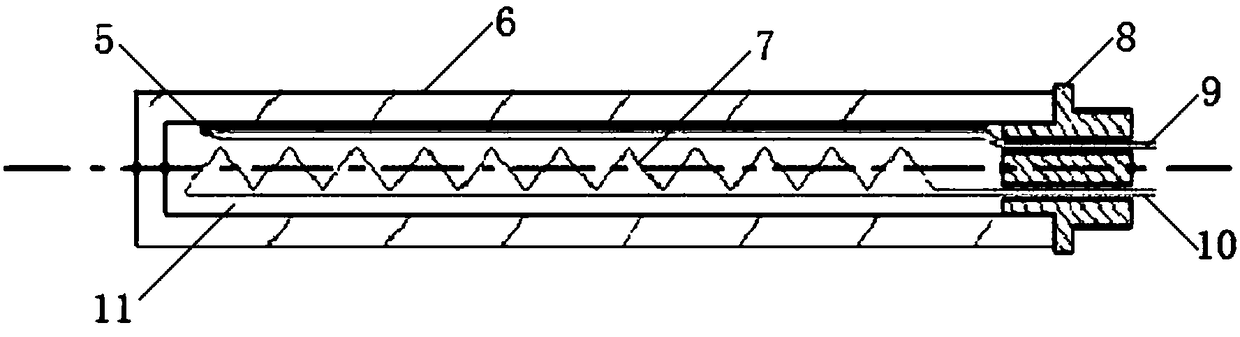

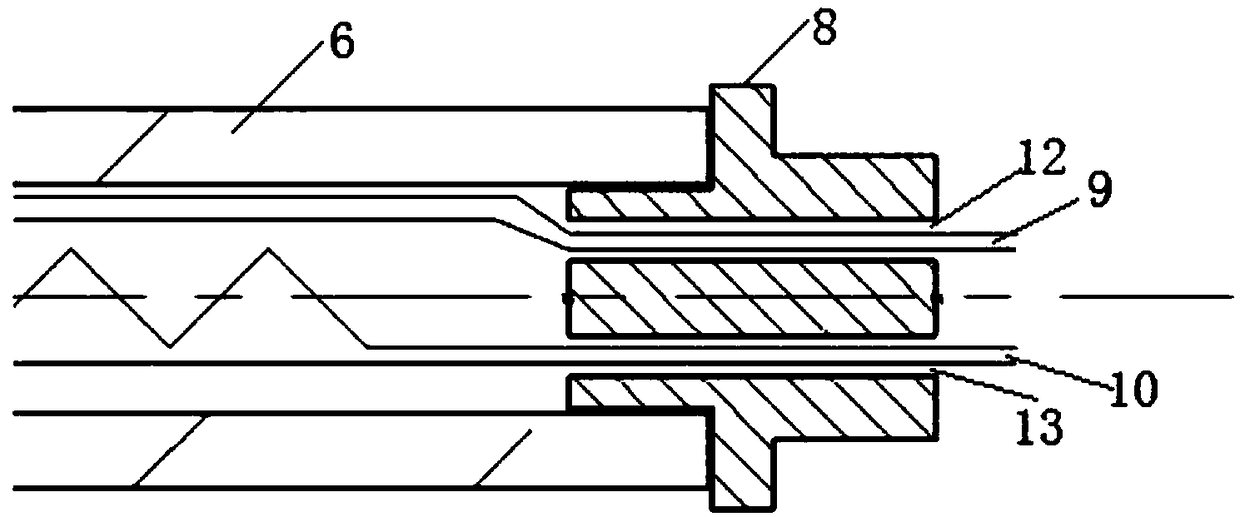

[0035] The spray intensity probe 1 is a hollow structure with an opening at one end, preferably a hollow cylinder in this embodiment; the outermost side of the spray intensity probe 1 is provided with a spray probe housing 6, which protects internal components and transmission The effect of heat; the spray intensity probe 1 is provided with a hollow cavity 11, and the opening at one end of the spray intensity probe 1 is provided with a tail end cover 8, and the spray probe shell 6 and the tail end cover 8 make the hollow cavity 11 form a closed space; The hollow cavity 11 is provided with a temperature measuring element 5, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com