Single mold form fryer with product centering elements

A fryer, food technology, applied in the field of forming fryer device for manufacturing snack food, can solve the problem that it is difficult to provide bottom conveyor belt for cooked products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

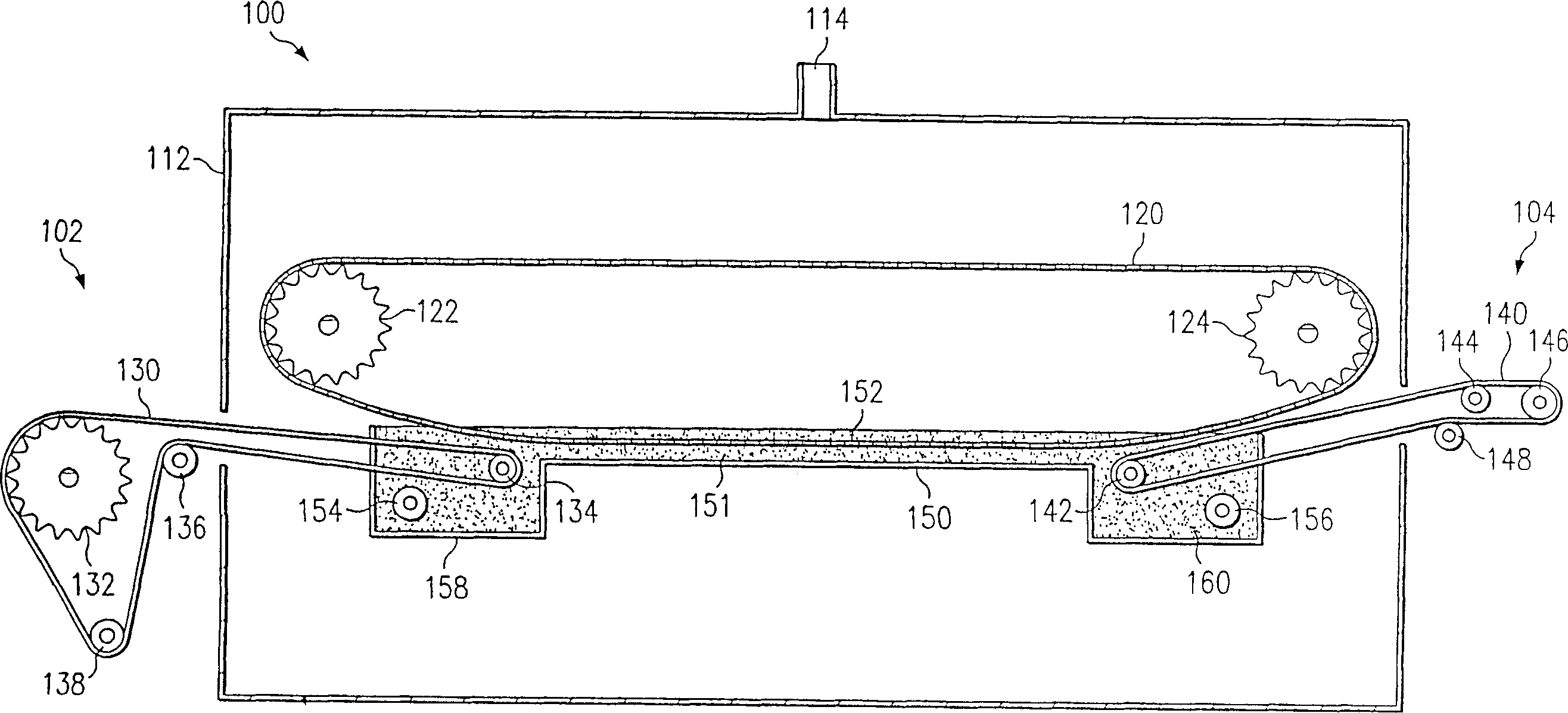

[0038] The formed fryer for frying snack products according to one embodiment of the present invention is figure 2 shown in . Fryer apparatus 100 receives snack products to be fried at input area 102 . The snack product exits the fryer device 100 at an output area 104 after frying. Between the input area 102 and the output area 104 is a fryer housing 112 having a port 114 for controlling the fryer environment for cooking snack products. Although a single port is shown in the figure, the port 114 is only a representative of multiple ports, and these ports can be provided as required to realize other embodiments. As shown, the fryer apparatus 100 may be used to cook snack chips made primarily of potatoes, such as a dough comprising thinly sliced dehydrated potatoes. However, snack chips formed using the present invention may optionally consist of a starch-containing mixture.

[0039] The dough intended to be used to form the desired snack chips is formed and cut into pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com