Paper machine control method, control device, program and storage medium

A control method and technology of a control device, which are applied in paper machine, wet end of paper machine, ratio control, etc., can solve problems such as mutual interference, reduction of stability, and change of ash content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

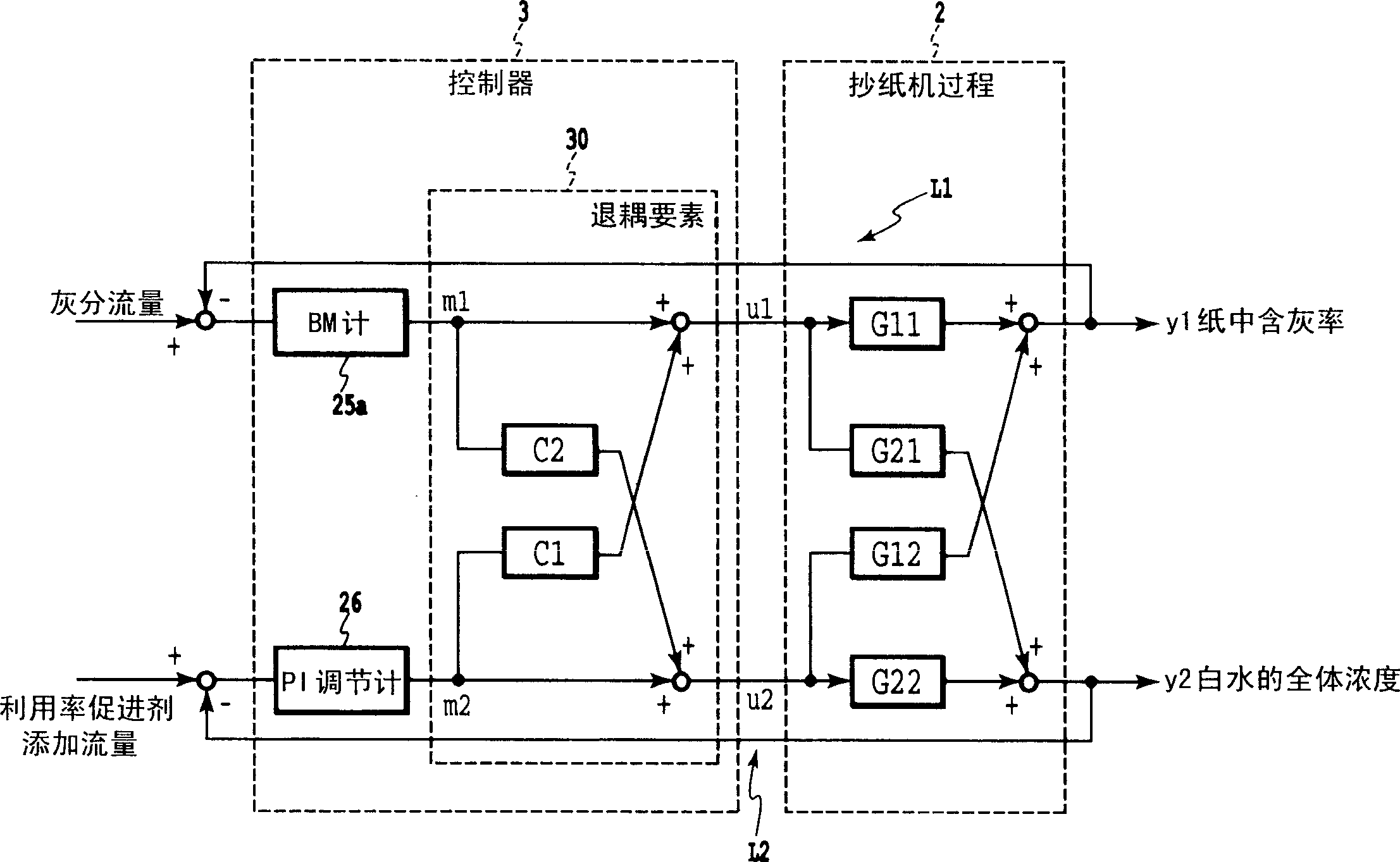

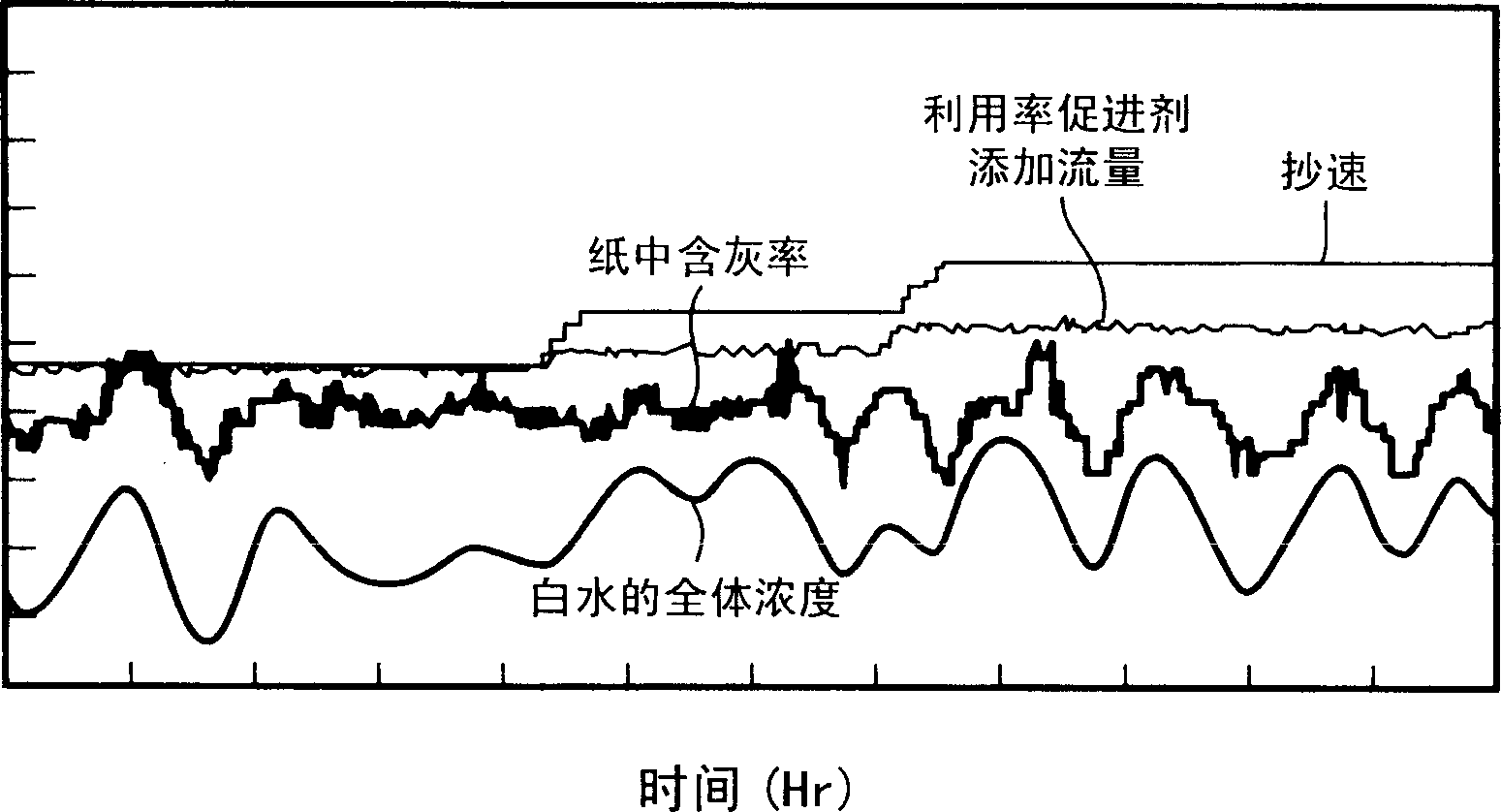

[0050] Embodiments of the present invention will be described below with reference to the drawings.

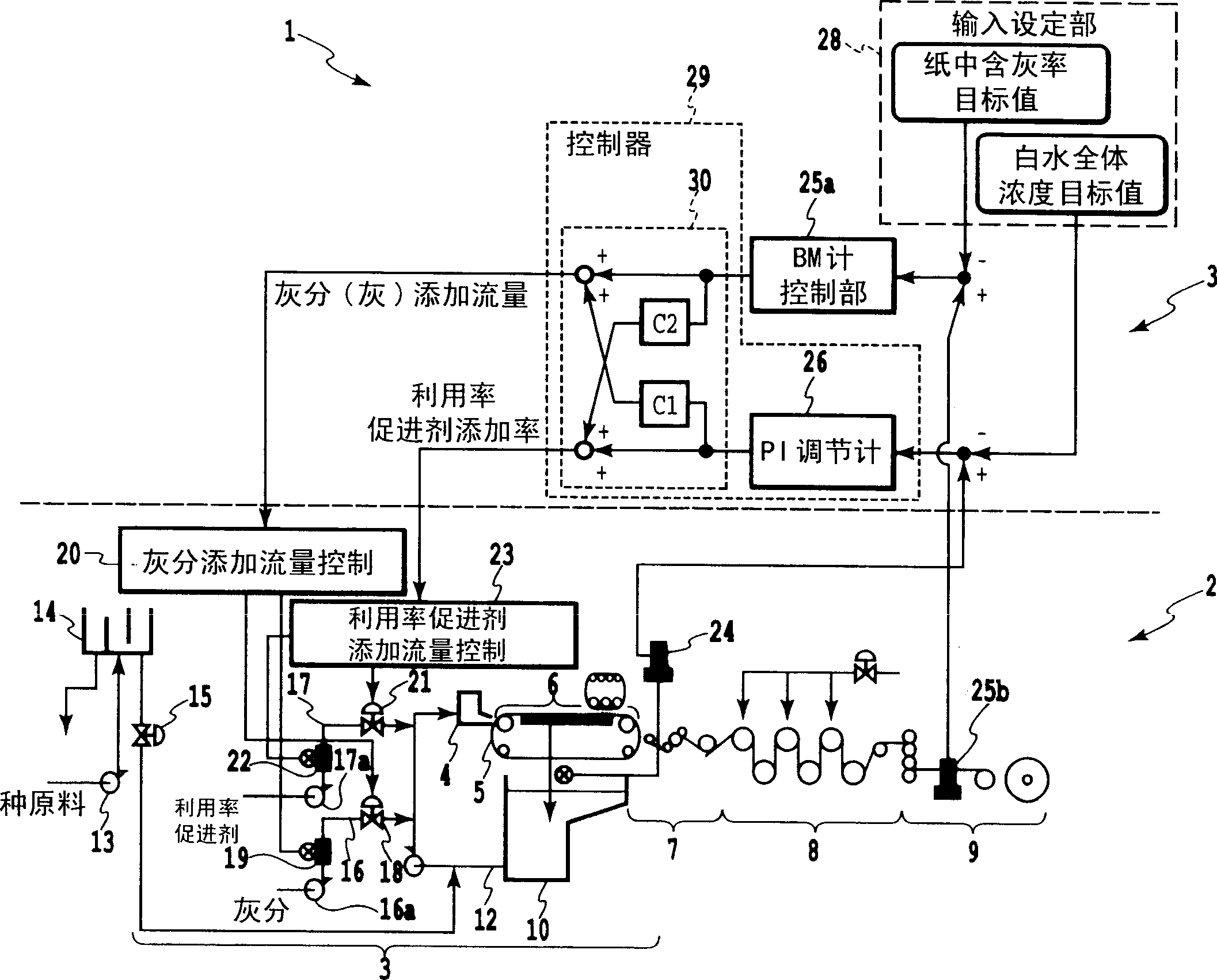

[0051] figure 1 It is a figure which schematically shows the whole structure of the paper machine used in one Embodiment of this invention.

[0052] As shown in the figure, the paper machine 1 shown here is composed of a paper machine process 2 that executes a papermaking process described later, and a control system 3 that controls the paper machine process 2 .

[0053] Here, first, the configuration of the paper machine process 2 will be described.

[0054] In the wet part 2a of the paper machine process 2, after the low-concentration seed material ejected from the head box 4 is dehydrated by the wire part 6 equipped with a continuously rotating wire 5, etc., the seed material remaining on the wire The pulp mat (pulp mat) on 5 is transported to the extrusion part 7 of the subsequent stage, where it is dewatered again. In addition, the pulp mat dehydrated by the pressing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com