Method and device for electrostatic coating

A technology for electrostatic spraying and spraying materials, applied in the direction of liquid supply device, etc., can solve the problems of increasing the amount of conductive spraying materials, uneconomical and enlarged electrostatic spraying equipment, etc., and achieve simple treatment and installation, economical and effective electrostatic spraying treatment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

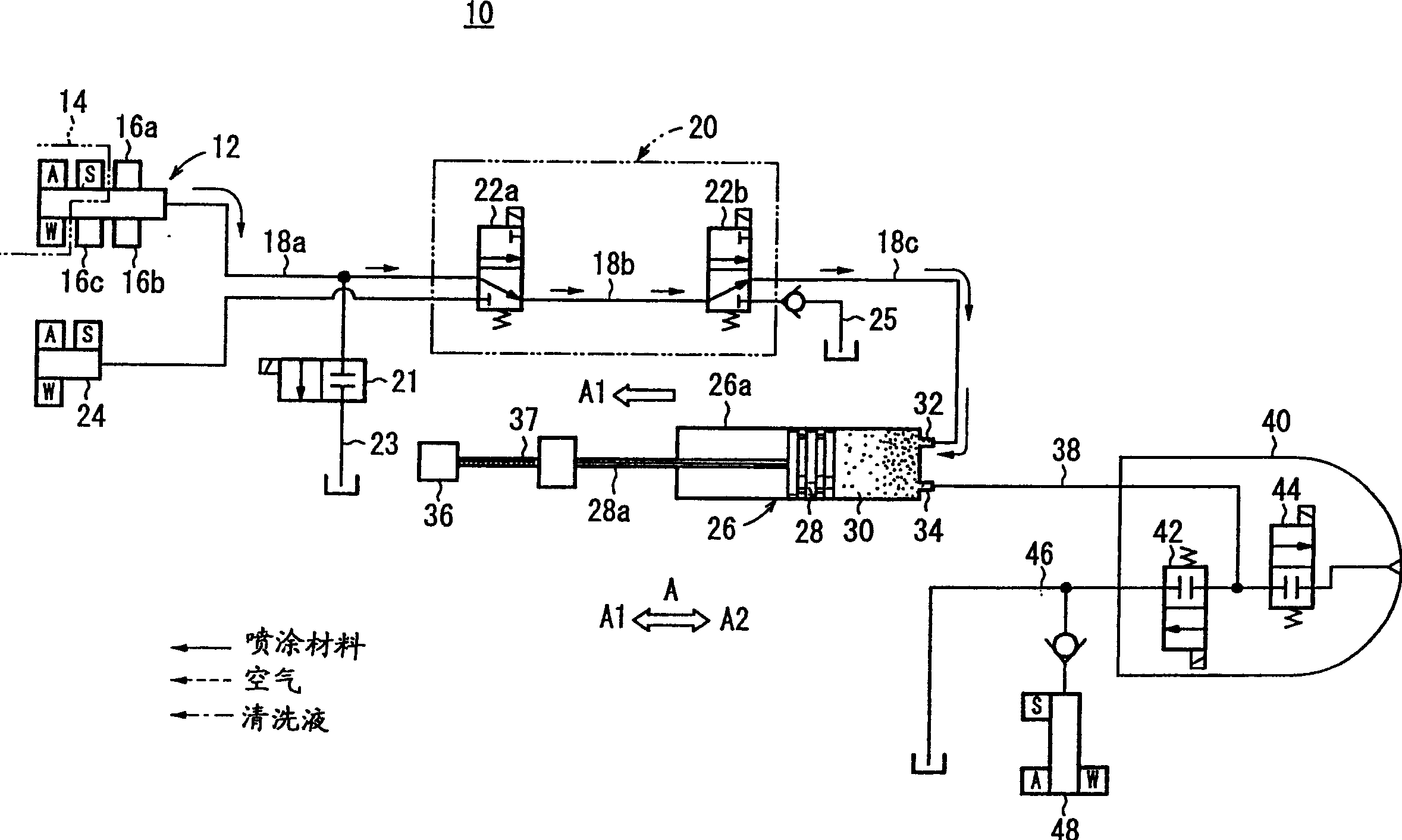

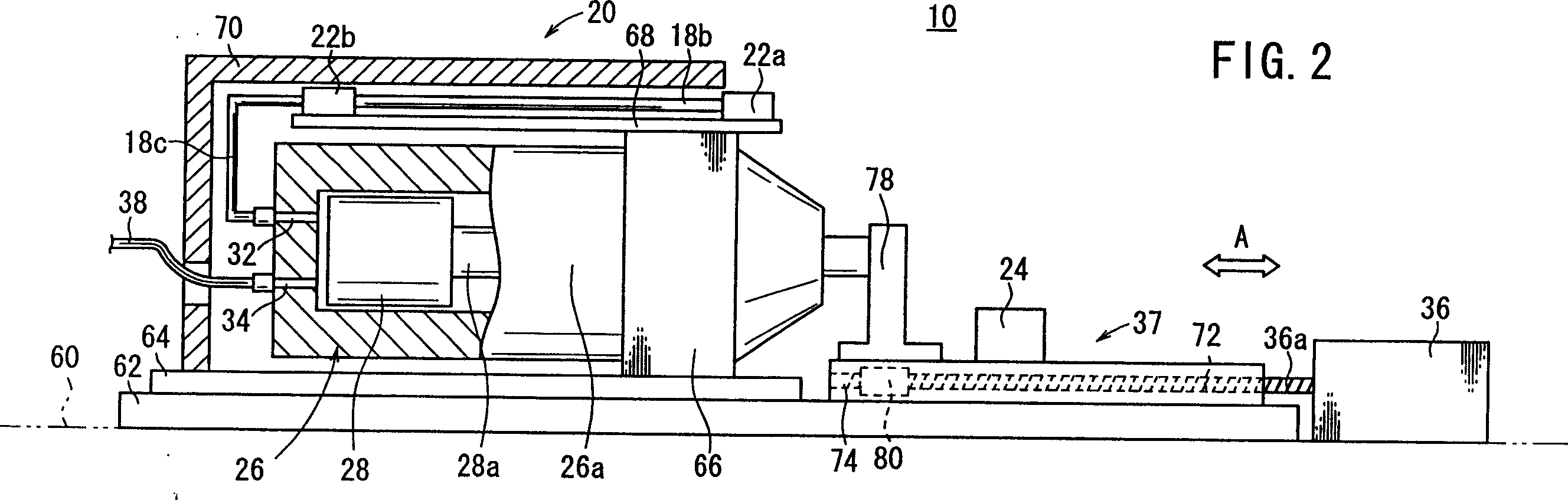

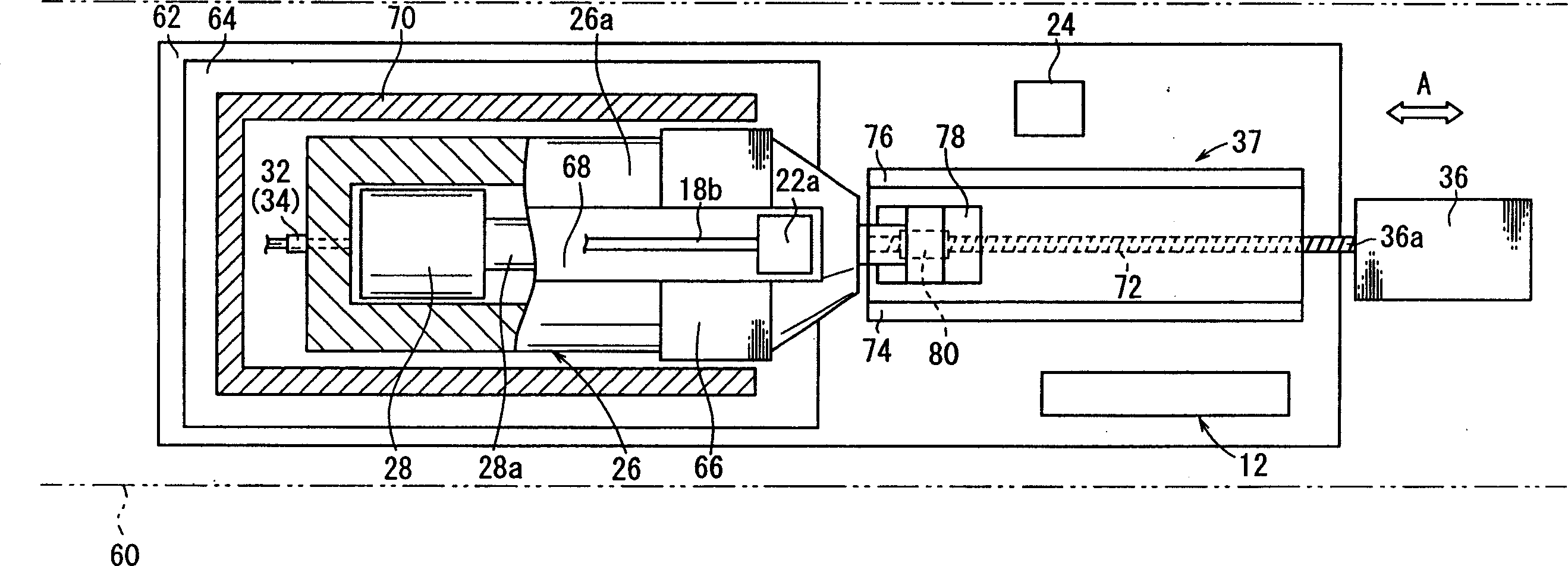

[0039] FIG. 1 is a schematic diagram of an electrostatic spraying apparatus 10 for performing an electrostatic spraying method according to the present invention.

[0040] The electrostatic spraying apparatus 10 includes a grounded color changer valve mechanism 12 with a first purge valve 14 for controlling the supply of drying air (A), water (W), cleaning solution (S) etc. A plurality of spray material valves 16a, 16b, 16c for conductive spray material. The choke valve mechanism 20 is connected to the color changer valve mechanism 12 through the supply passage 18 a, and the first discharge passage 23 is connected to the supply passage 18 a through the first damper valve 21 .

[0041] The choke valve mechanism 20 has an electrically insulating tube (supply passage) 18b made of resin and a pair of directional control valves 22a, 22b connected to respective opposite ends of the electrically insulating tube 18b. The directional control valve 22a on the inlet side selects one of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com