Shaft drive for a mechanical weaving loom

A drive and heald frame technology, applied in textile, heald, dobby and other directions, to achieve the effect of good sealing function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

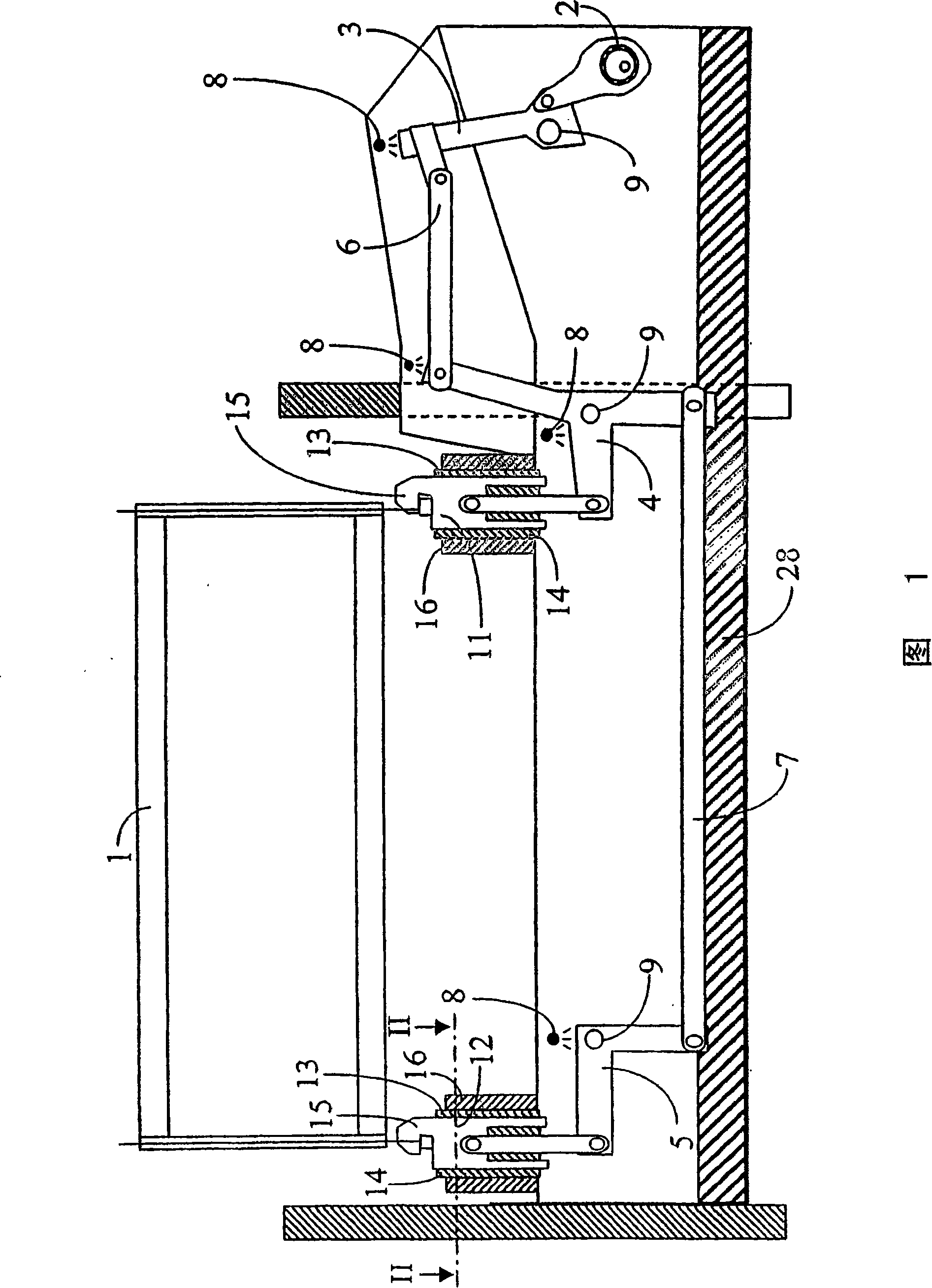

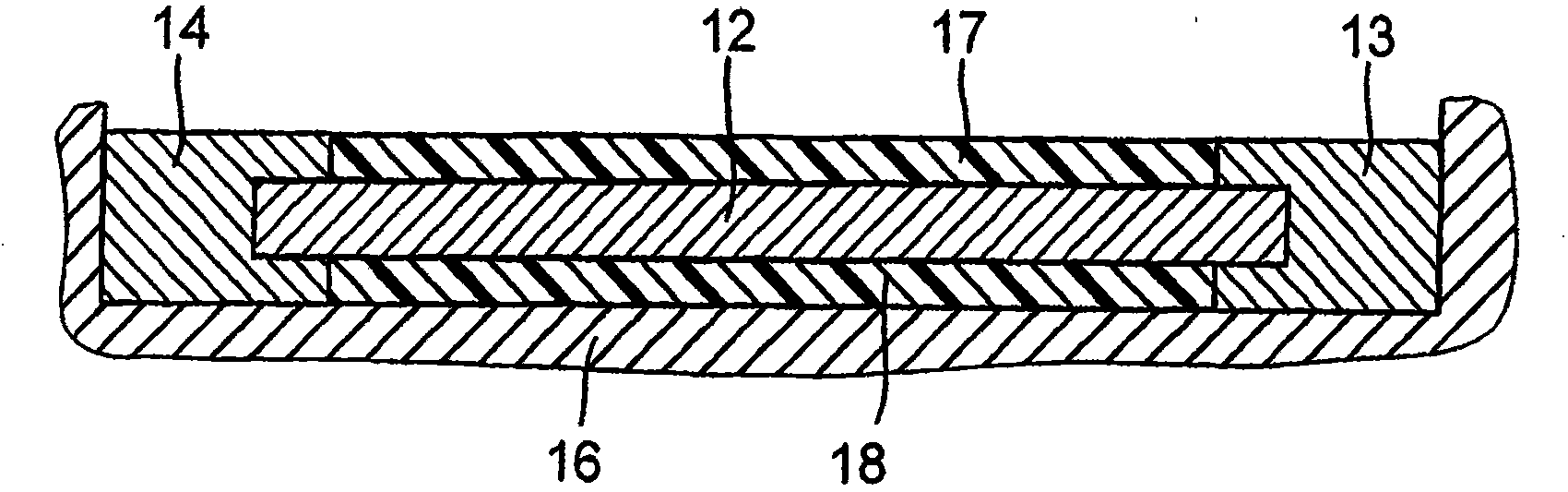

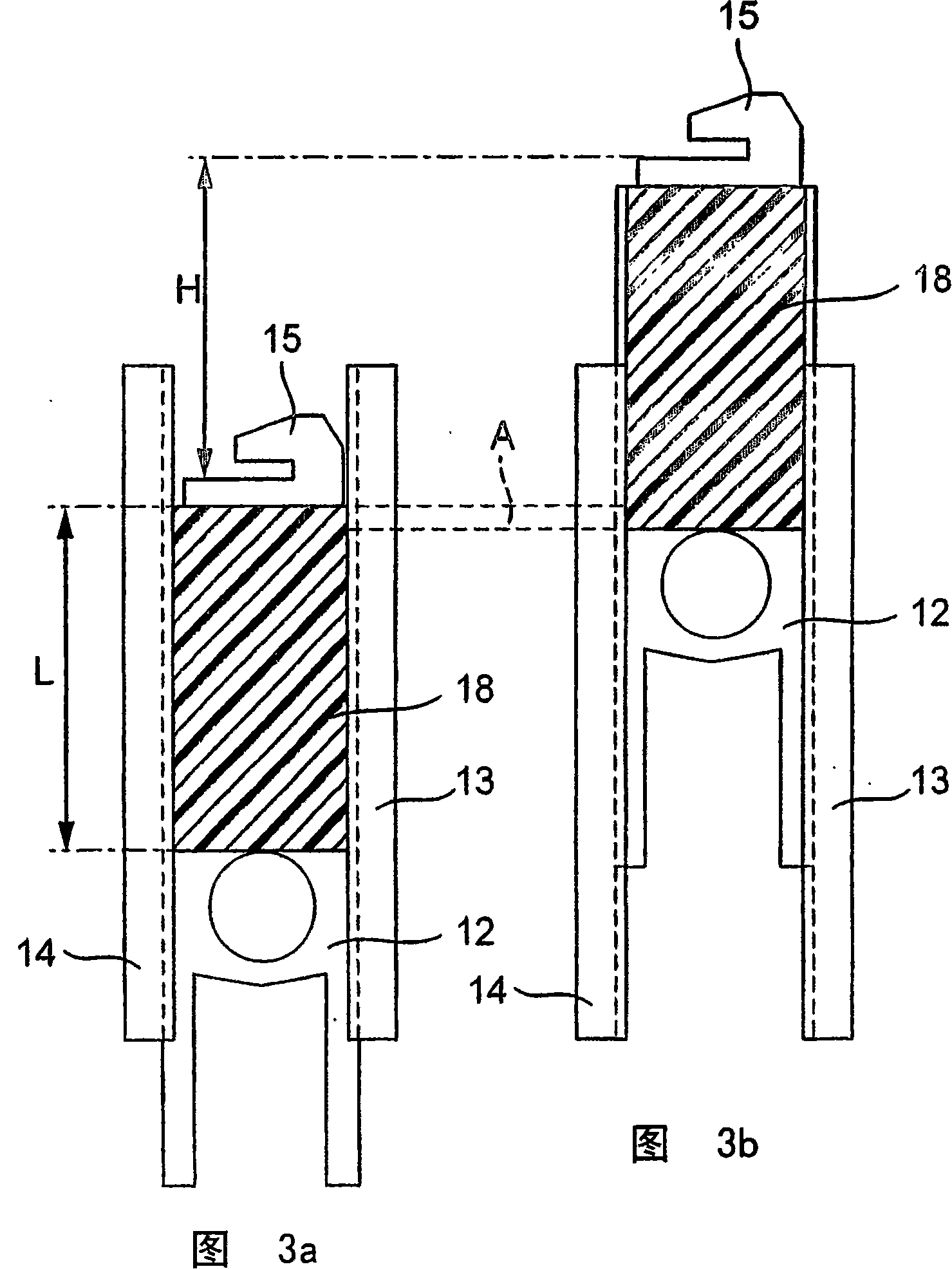

[0032] exist figure 1 The illustrated heald frame drive for a weaving machine has a longitudinally extending, for example rectangular in cross section, housing 10 which is arranged in the lower region of the heald frame 1 within the weaving machine. Drive elements 2 , 3 , 4 , 5 , 6 and 7 are located inside the housing, and they are driven by a driver, not shown, which is arranged outside the housing 10 in a slightly elevated position at the figure 1 center on the right. The drive mechanism drives transmission elements 11 and 12 , which are guided in linear guides 13 , 14 . The transfer elements 11 , 12 are provided at their ends with hooks 15 which serve as connection means for receiving parts of the heald frame, as is known from EP 0520540 B1. In the exemplary embodiment, two transfer elements 11 , 12 are provided. However, for larger weaving widths, three or more such transmission elements can also be provided, that is to say, additionally for the two transmission element...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com