Compressors muffler

A muffler and compressor technology, applied in the field of compressors, can solve the problems of cost increase, large impact noise, etc., and achieve the effect of cost reduction and avoid impact noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

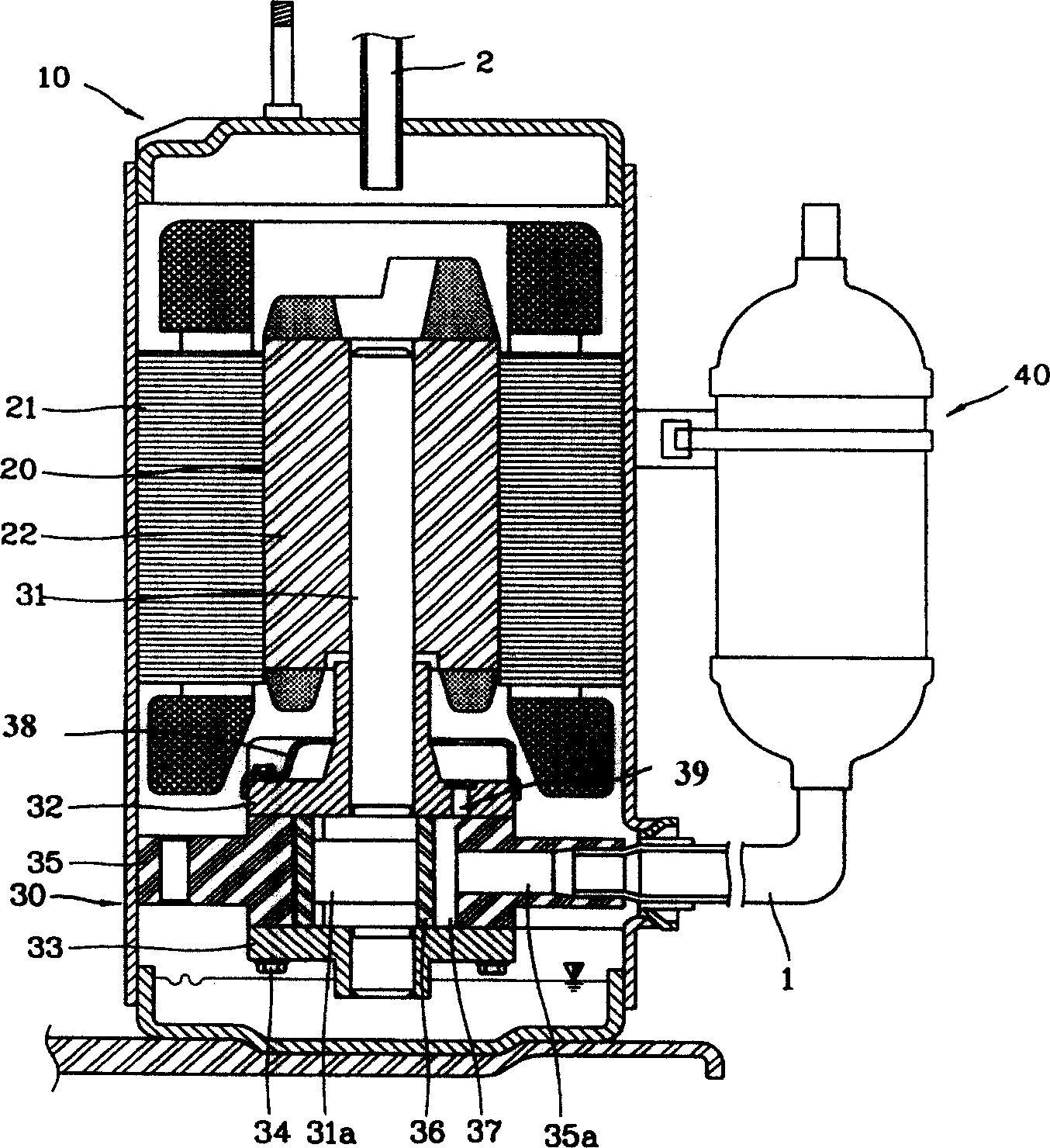

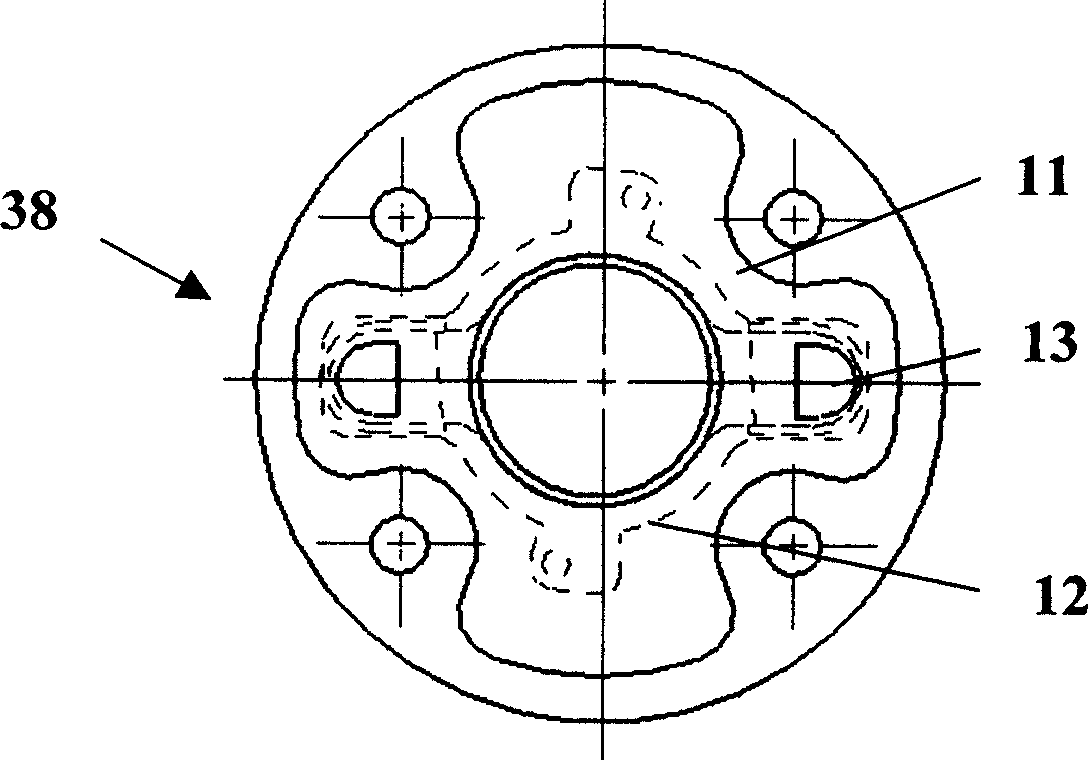

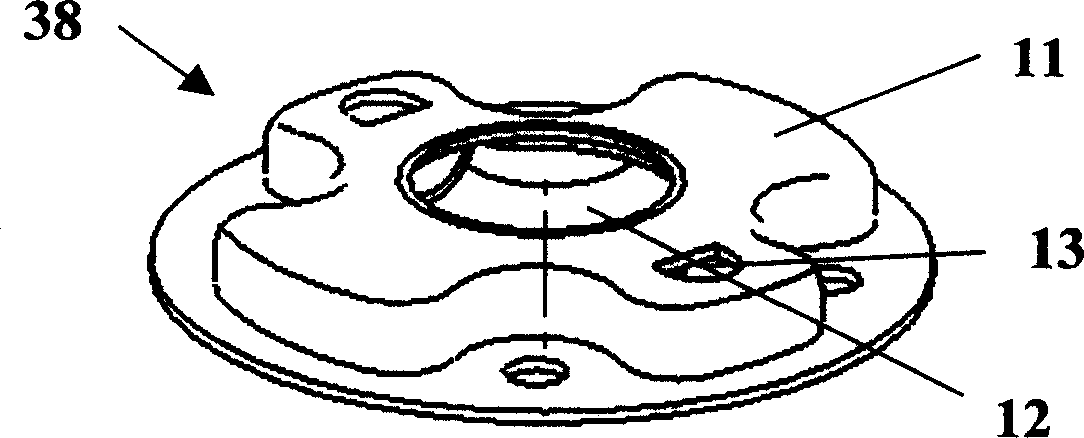

[0011] Such as Figure 4 As shown, the compressor muffler 50 provided by the present invention consists of a cross-shaped protrusion 52 with a crankshaft through hole 51 formed in the center and a chassis 53 formed by extending outward from the lower end of the protrusion 52 in a horizontal direction and having a circular outer periphery. Composition; The two ends of the cross-shaped protrusion 52 are respectively provided with a discharge hole 54 penetrating in the radial direction and penetrating through the chassis 53 . When the compressor is running, the compression mechanical part 30 can compress the low-temperature and low-pressure gaseous refrigerant sucked from the liquid storage tank 40 through the suction pipe 1 into a high-temperature and high-pressure gaseous refrigerant, and then discharge the compressed refrigerant from the discharge port 39 on the upper bearing 32 into the muffler 38. The refrigerant entering the interior of the muffler 38 will flow in the hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com