Partition plate structure for closed compressor

A technology of dividing plates and compressors, applied in rotary piston machinery, rotary piston/swing piston pump parts, mechanical equipment, etc., can solve the problems of fluid leakage, impact noise, wear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The structure of the partition plate of the hermetic compressor of the present invention is specifically described below in conjunction with the accompanying drawings and embodiments:

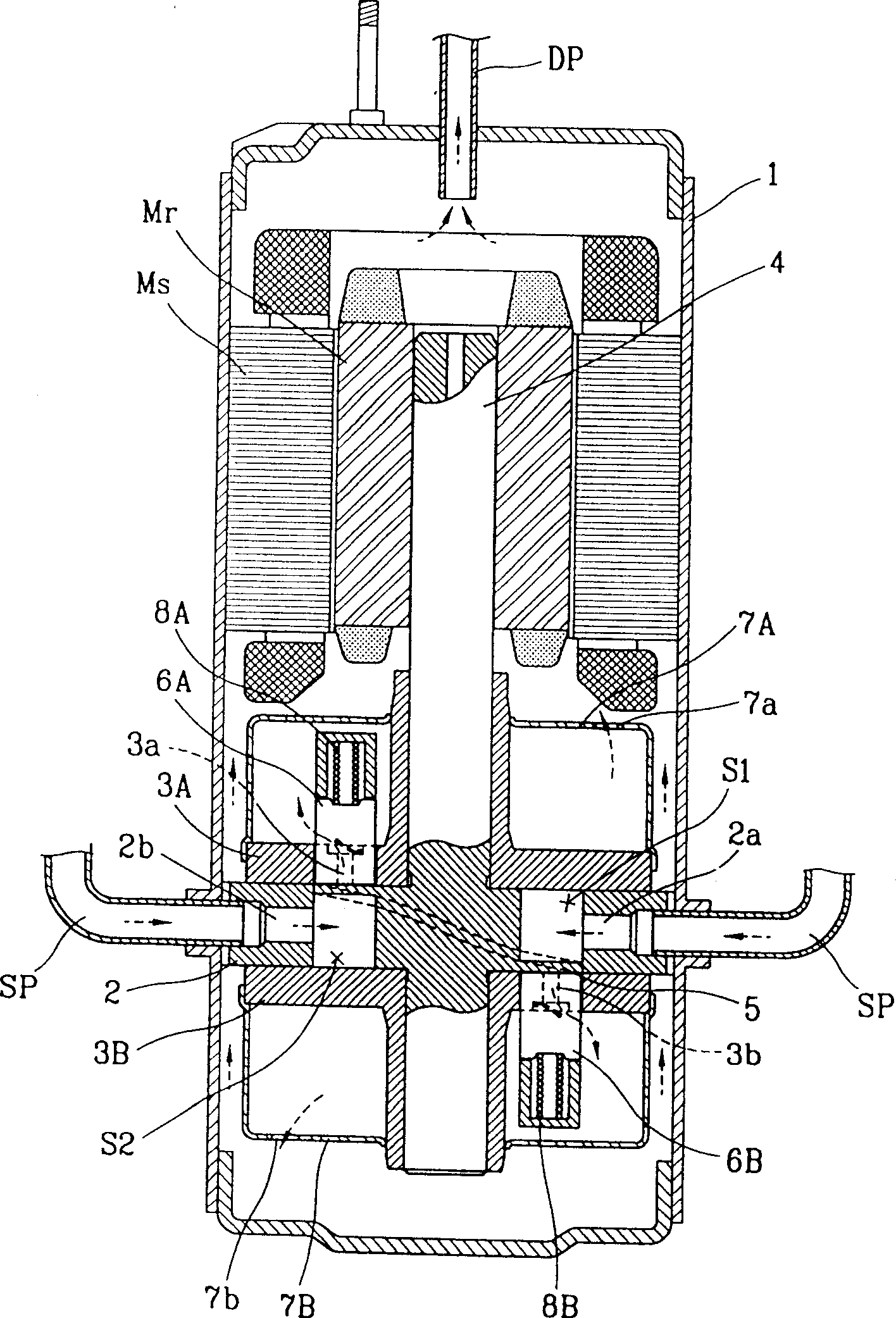

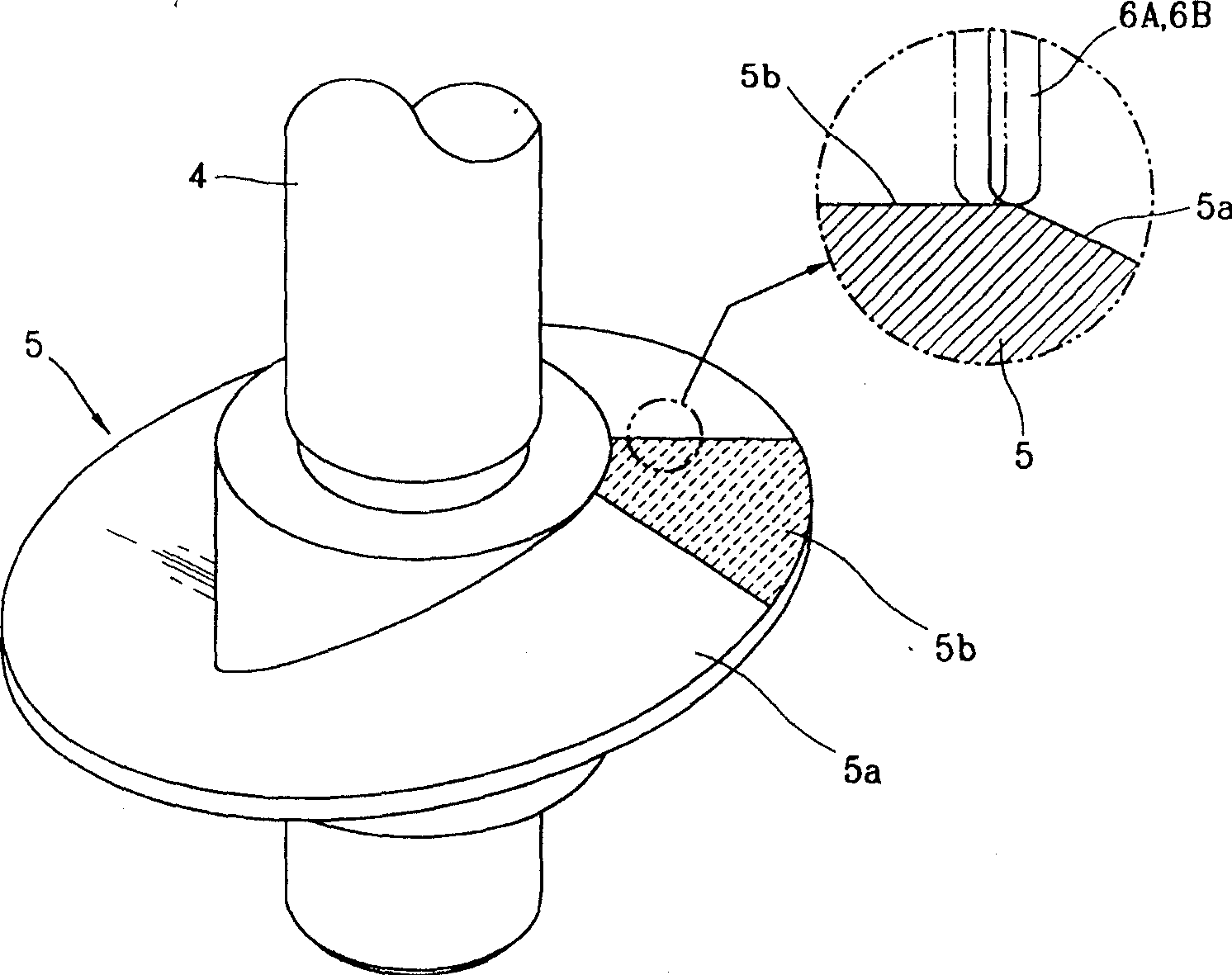

[0018] Such as figure 1 , 4 , 5, the partition plate structure of the hermetic compressor of the present invention includes the cylinder 2, the first support plate 3A, the second support plate 3B, the rotating shaft 4, the partition plate 10, the first sliding plate 6A and the second Slider 6B. Among them, the cylinder 2 is connected to one side of the motor assembly and fixed in the lower half of the casing 1; the first support plate 3A and the second support plate 3B are respectively fixed on the upper and lower sides of the cylinder 2 to form the inner space of the cylinder 2 together; The rotating shaft 4 is connected to the motor assembly, and at the same time passes through and combines with the support plates 3A, 3B to transmit the power of the motor assembly to the compressor a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com