Linear compressor

A linear compressor, linear motor technology, applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve the problems of reduced compressor efficiency, reduced compressor efficiency, reduced efficiency, etc., to maximize compression efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Next, based on the embodiments of the present invention and the accompanying drawings, it will be described that after the moving magnet linear motor is driven, the piston connected to it moves back and forth linearly inside the cylinder while sucking, compressing and discharging the refrigerant. Linear compressor. However, the rights of the present invention are not limited to the above-mentioned embodiments, but are defined by the description in the claims. Without departing from the technical scope of the present invention described in the claims, those skilled in the relevant industries can make various variations and modifications to it.

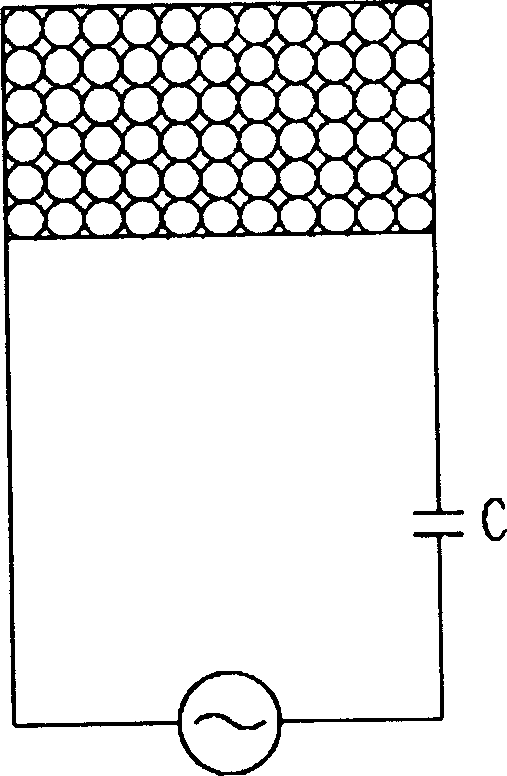

[0061] According to the linear compressor of the present invention such as image 3 As shown: one side of the airtight container 2 is provided with an inflow pipe 2a and an outflow pipe 2b for inflowing / outflowing the refrigerant; the cylinder 4 is fixedly arranged inside the airtight container 2; Refrigerant, and a piston 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com