Apparatus for changing capacity of multi-stage rotary compressor

A compressor capacity, compression chamber technology, applied in the direction of rotary piston machinery, pumping device components for elastic fluid, pump combination for elastic fluid rotary piston type/swing piston type, etc., can solve the installation space Not ideal, increased number of manufacturing processes, reduced reliability of compression units, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Reference will now be made in detail to the preferred embodiments of the present invention, examples of which are illustrated in the accompanying drawings. The same reference numerals refer to the same components as in the conventional art.

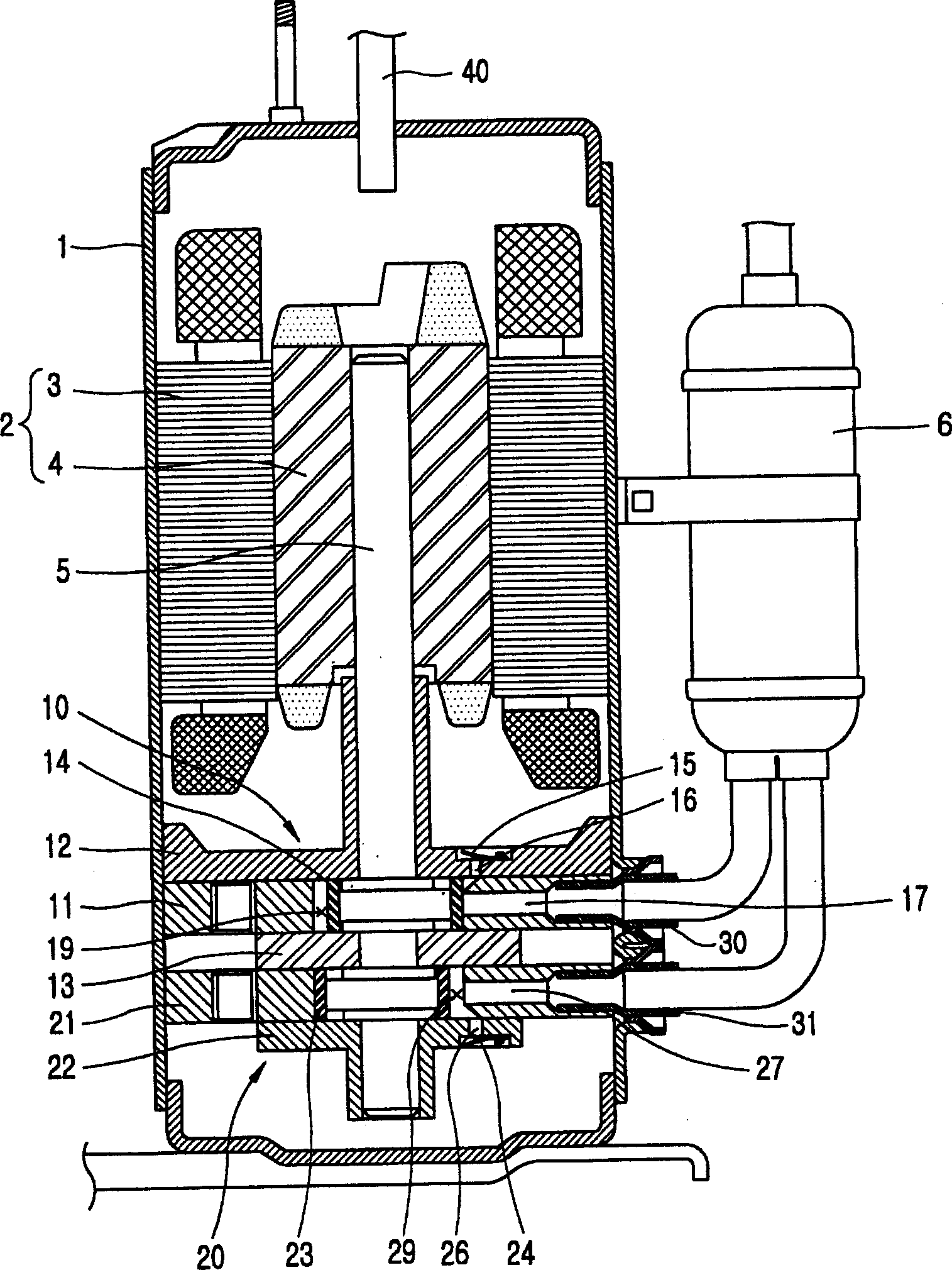

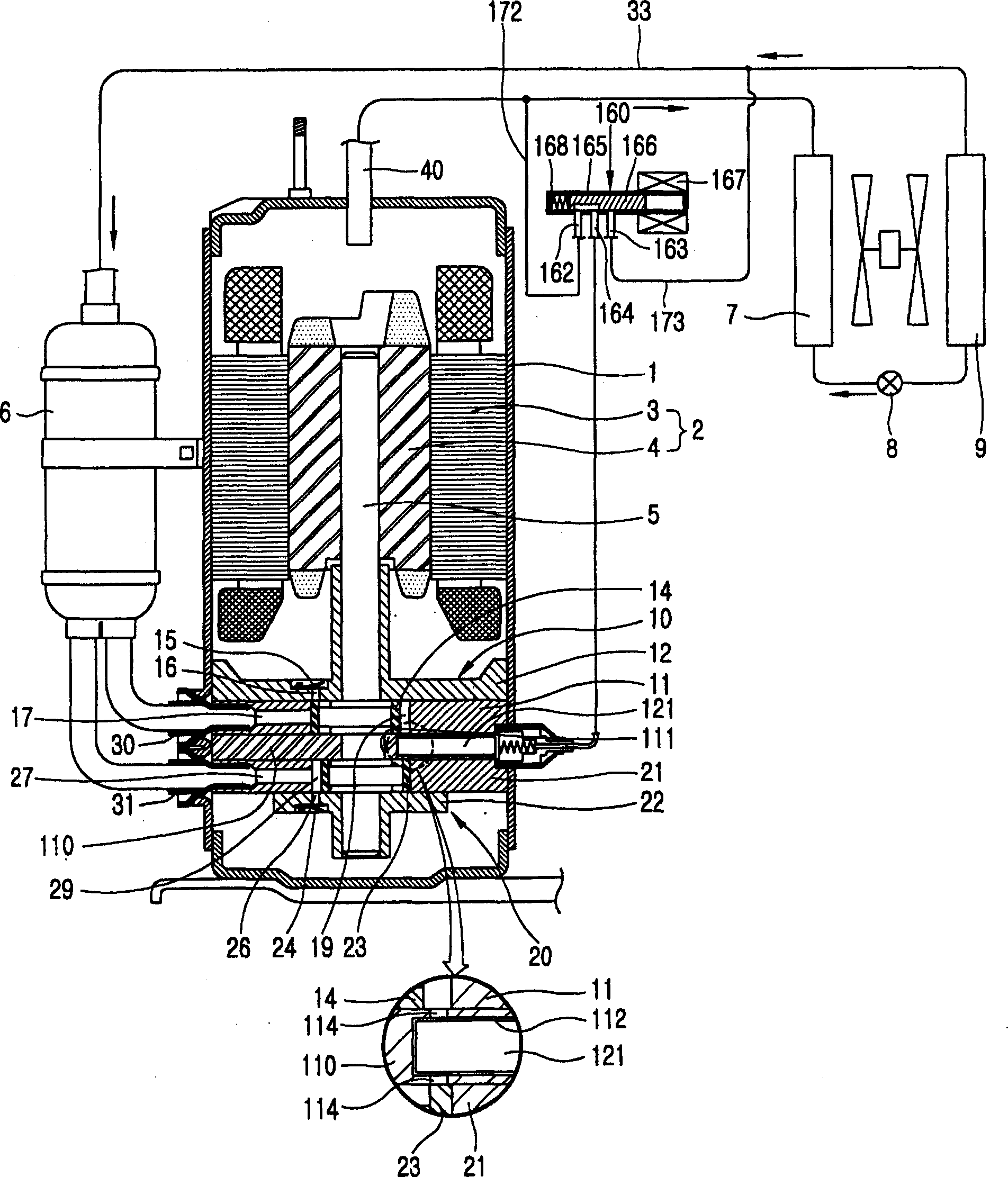

[0035] figure 2 A cross-sectional view of a multi-stage rotary compressor according to a first embodiment of the present invention is shown.

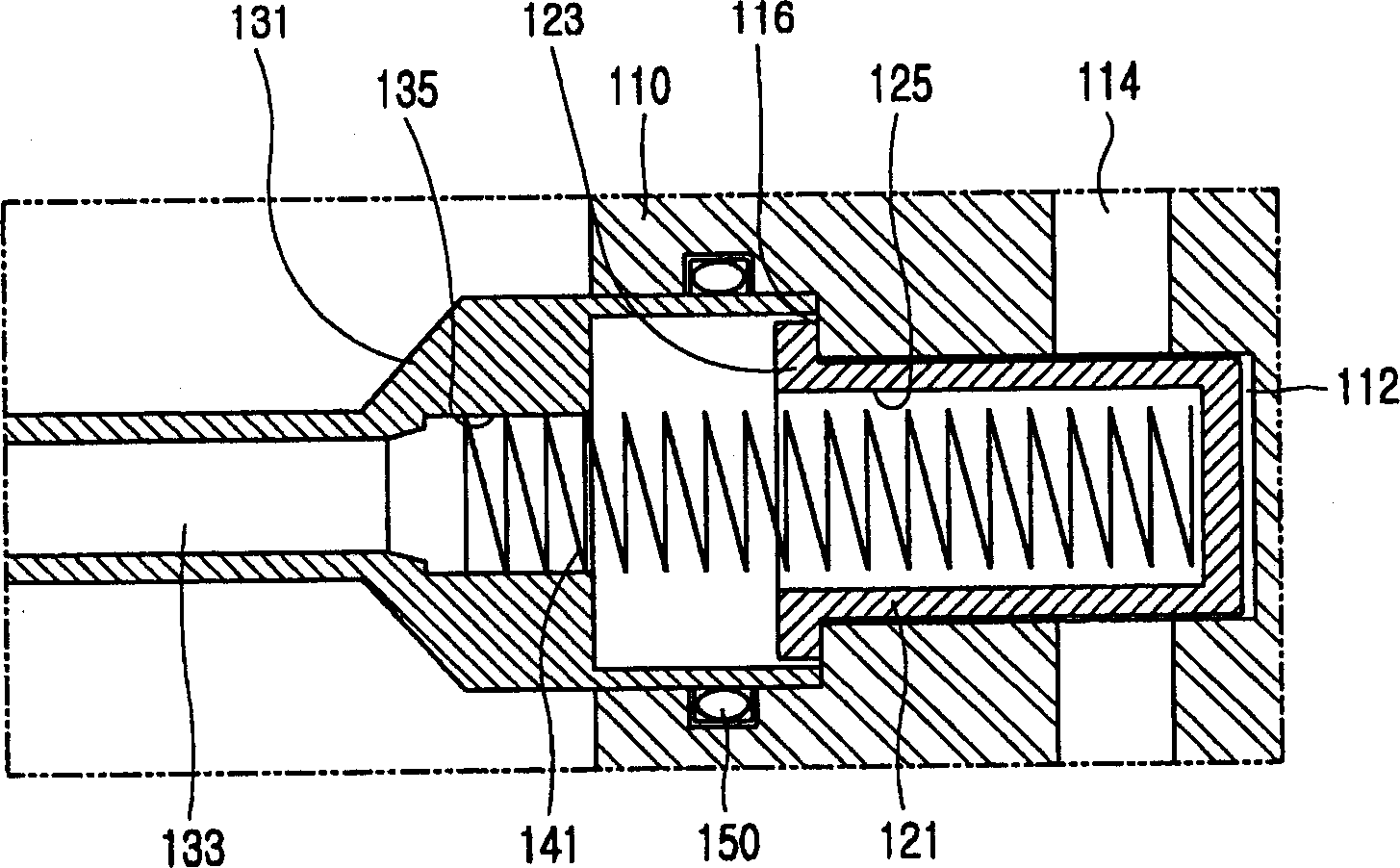

[0036] As shown in the figure, the multi-stage rotary compressor according to the present invention includes: a casing 1 equipped with a plurality of suction pipes 30 and 31 communicating with each other and a discharge pipe 40; A motor unit 2 generating a rotational force; a first compression unit 10 and a second compression unit 20 mounted on the lower side of the housing 1 in a multi-stage manner, for receiving the rotational force generated by the motor unit 2 through the rotating shaft 5 respectively compressing refrigerant; a first slide valve 121 selectively communicating with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com