Lower ventilating structure of elevator car

An elevator car and car technology, which is applied to elevators, transportation and packaging in buildings, can solve the problems of troublesome elevator reconstruction and high cost, and achieve the effects of convenient operation, low production cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following is based on Figure 1-Figure 3 A preferred embodiment of the present invention is given.

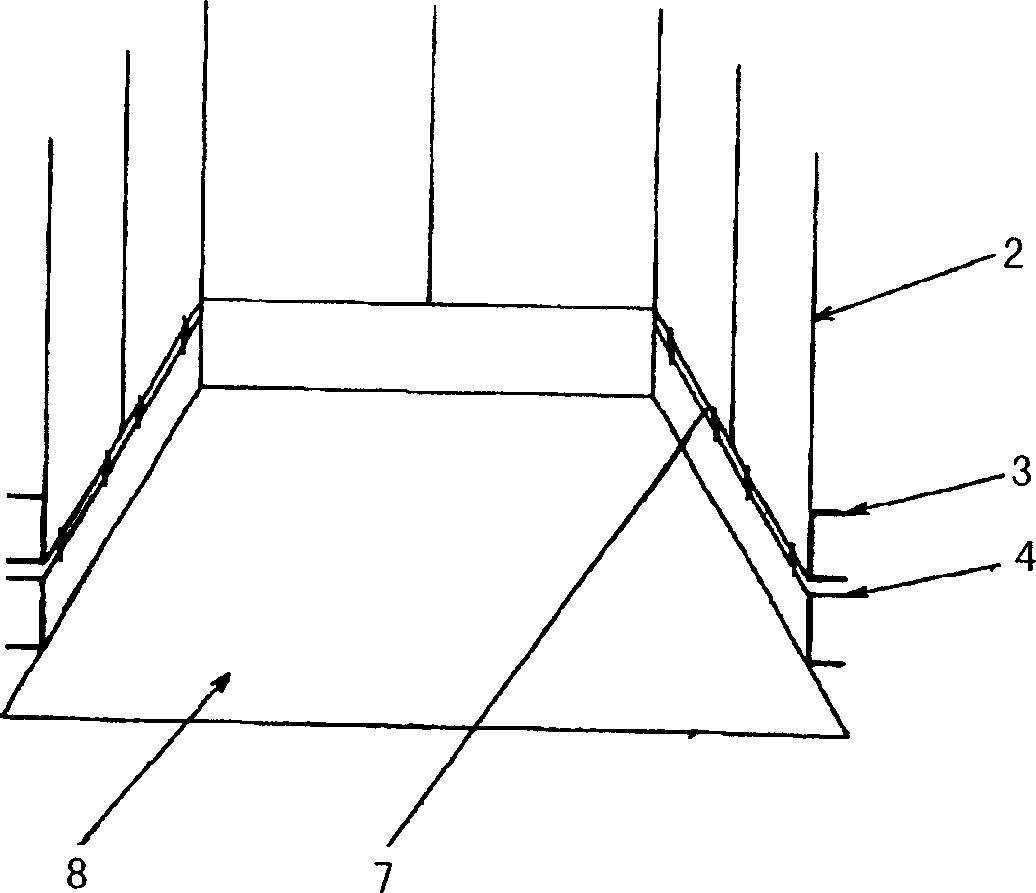

[0020] Such as figure 1 As shown, the elevator car includes: car wall panels 2 , car wall panel reinforcing ribs 3 , skirting boards 4 , ventilation slits 7 and car floor panels 8 .

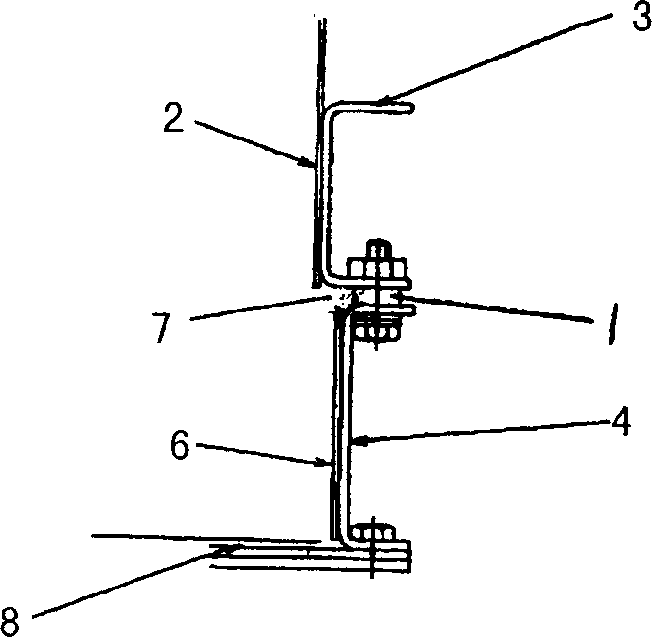

[0021] Such as figure 2 As shown, it includes: car wall plate 2; car wall plate reinforcing rib 3 installed on the back of car wall plate 2, wherein the car wall plate reinforcing rib 3 is to increase the strength of car wall plate 2, and through the car wall plate reinforcing rib 3, the skirting board 4 is arranged on the lower side of the car wall board 2, the car wall board reinforcing rib 3 and the skirting board 4 are connected by threads, and a screw thread is set between the car wall board reinforcing rib 3 and the skirting board 4 Support sleeve 1. Also by threaded connection between skirting board 4 and car bottom panel 8.

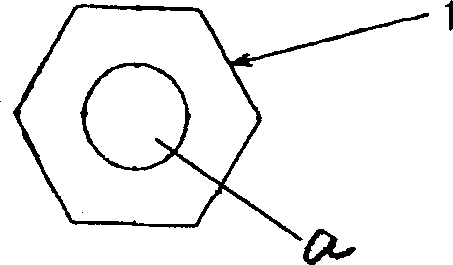

[0022] Such as image 3 As shown, there is a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com