3D packaging material for automatic packaging, cigarette case and manufacturing method thereof

A packaging material and manufacturing method technology, applied in chemical instruments and methods, rigid/semi-rigid container manufacturing, packaging, etc., can solve the problems of poor heat resistance of the surface of the grating material and the inability to apply in the field of automated packaging, and achieve no impact The effect of mechanical strength, material cost saving and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

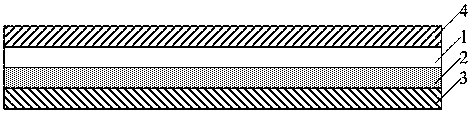

[0052] Such as figure 1 As shown, the 3D packaging material for automatic packaging in this embodiment includes a grating material layer 1, a pattern layer 2 arranged on the bottom surface of the grating material layer 1; a wear-resistant layer 3 arranged on the bottom surface of the pattern layer 2; and setting A heat-resistant layer 4 on top of the grating material layer 1 .

[0053] Wherein, the grating material layer 1 may be a grating plate of polystyrene (PET), polypropylene (PP) or polyvinyl chloride (PVC). The pattern layer 2 can be a pattern layer formed by colored ink printed on the bottom surface of the grating material 1. Wear-resistant layer 3 can be the packaging paper, cardboard, plastics, film, ink, varnish, or glass that is printed or laminated on the bottom surface of pattern layer 2, and it is used for increasing frictional force, and in mass packaging production process, The direct contact between the grating material 1 and the automatic conveying device ...

Embodiment 2

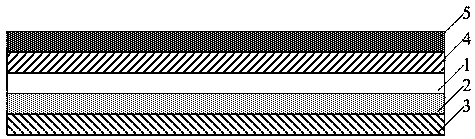

[0065] Such as figure 2 As shown, the 3D packaging material for automatic packaging in this embodiment also includes a decorative layer 5 disposed on the heat-resistant layer 4. The decorative layer 5 covers the heat-resistant layer 4 completely, that is, the setting area of the decorative layer 5 overlaps with the top surface area of the heat-resistant layer 4 completely.

[0066] Decorative layer 5 can be pasted, printed, hot stamped or adopt processes such as thermal transfer, cold transfer to be arranged on the top surface of heat-resistant layer 4, and decorative layer 5 can be anodized aluminum, printing ink, sticker or film etc. It is used to make the products more visually impactful and aesthetically pleasing, and can achieve common effects such as bronzing. All the other are identical with embodiment 1.

Embodiment 3

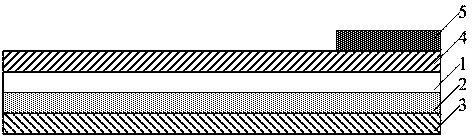

[0068] Such as image 3 As shown, the 3D packaging material for automatic packaging in this embodiment also includes a decorative layer 5 disposed on the heat-resistant layer 4. The decorative layer 5 partially covers the heat-resistant layer 4, that is, the setting area of the decorative layer 5 does not overlap with the top surface area of the heat-resistant layer 4, so that the produced product has more visual impact and aesthetics, and common effects such as bronzing can be achieved .

[0069] Decorative layer 5 can be pasted, printed, hot stamped or adopt processes such as thermal transfer, cold transfer to be arranged on the top surface of heat-resistant layer 4, and decorative layer 5 can be anodized aluminum, printing ink, sticker or film etc. All the other are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com