Lens assembly structure for rimless glasses

A technology for lens assembly and rimless glasses, applied in the directions of glasses/protective glasses, glasses/goggles, optics, etc., it can solve the problems of small outward pulling force, easy connection loose, and difficult to fasten, so as to resist the impact of external force , Solve the effect of loose lens and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

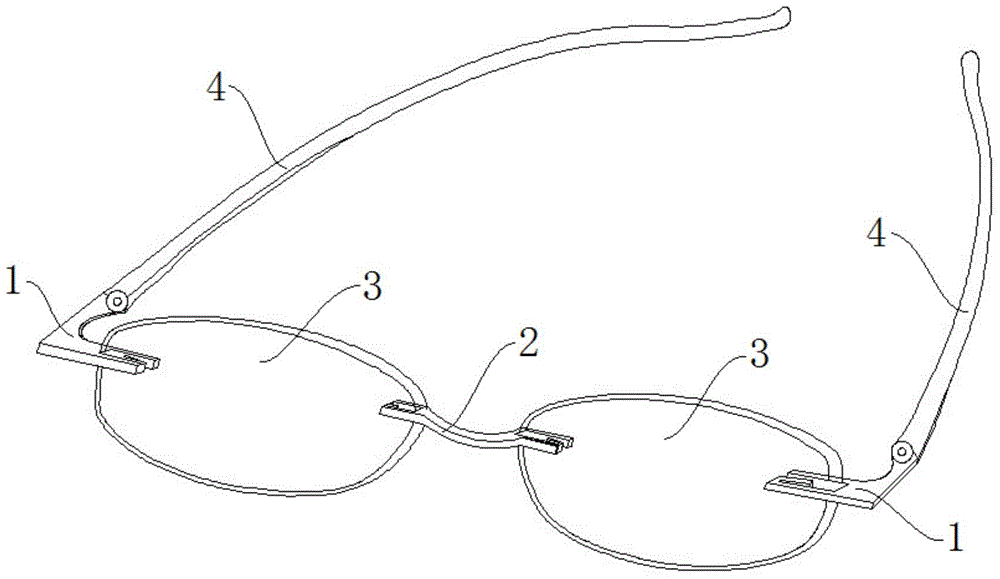

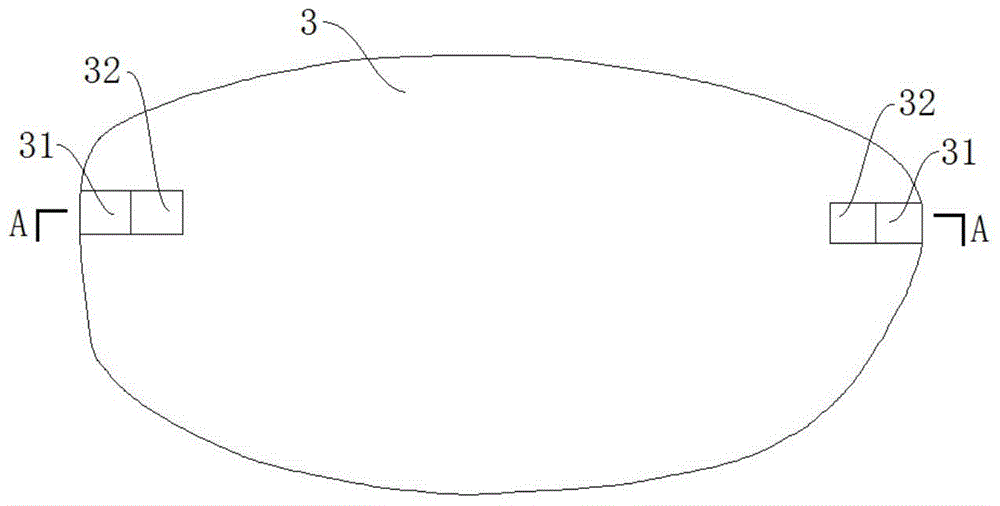

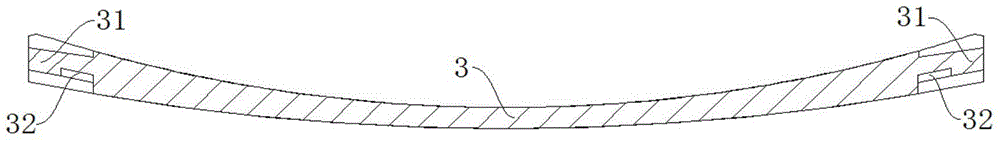

[0040] combine figure 1 , a kind of lens assembly structure of the rimless glasses of the present embodiment, comprises pile head 1, bridge of the nose 2 and lens 3, as figure 2 and image 3 As shown, the front and rear sides of the lens 3 are grooved to form two inserts 31 respectively connected to the pile head 1 and the bridge of the nose 2. The inserts 31 are provided with grooves 32 close to the inside of the lens 3, that is to say, the two sides of the lens 3 are respectively An insertion piece 31 is provided, and a groove 32 is opened on the insertion piece 31 , one insertion piece 31 is used for connecting with the pile head 1 , and the other insertion piece 31 is used for connecting with the bridge of the nose 2 . Such as Figure 4 and Figure 5 As shown, both the pile head 1 and the bridge of the nose 2 in this embodiment have a special structural design, and one end of the pile head 1 connected to the lens 3 is provided with a first pincer-shaped opening 11, and...

Embodiment 2

[0044] combine Figure 8 to Figure 11 , the basic structure of the lens assembly structure of a kind of rimless glasses of this embodiment is the same as that of Embodiment 1, the difference is that this embodiment is further improved on the basis of Embodiment 1, and the first pincer opening 11 is provided with One side jaw of the first elastic piece 12 is provided with the first boss 13, and the size between the first boss 13 and the jaw of the other side is equal to the thickness of the insertion piece 31, makes the first boss 13 and the other side The pincers clamp the inserting piece 31; the second boss 23 is arranged on the side of the second pincer-shaped opening 21 provided with the second elastic piece 22, and the second boss 23 and the other side of the pincers The size is equal to the thickness of the insertion piece 31, so that the second boss 23 and the clamp piece on the other side clamp the insertion piece 31, and the clamping effect of the first boss 13 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com