Gray inks for ink-jet printing

A technology of inkjet printing and ink, applied in the direction of ink, printing, application, etc., can solve the problems of high ink, loss of dark area details, outflow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] ink set

Embodiment 2

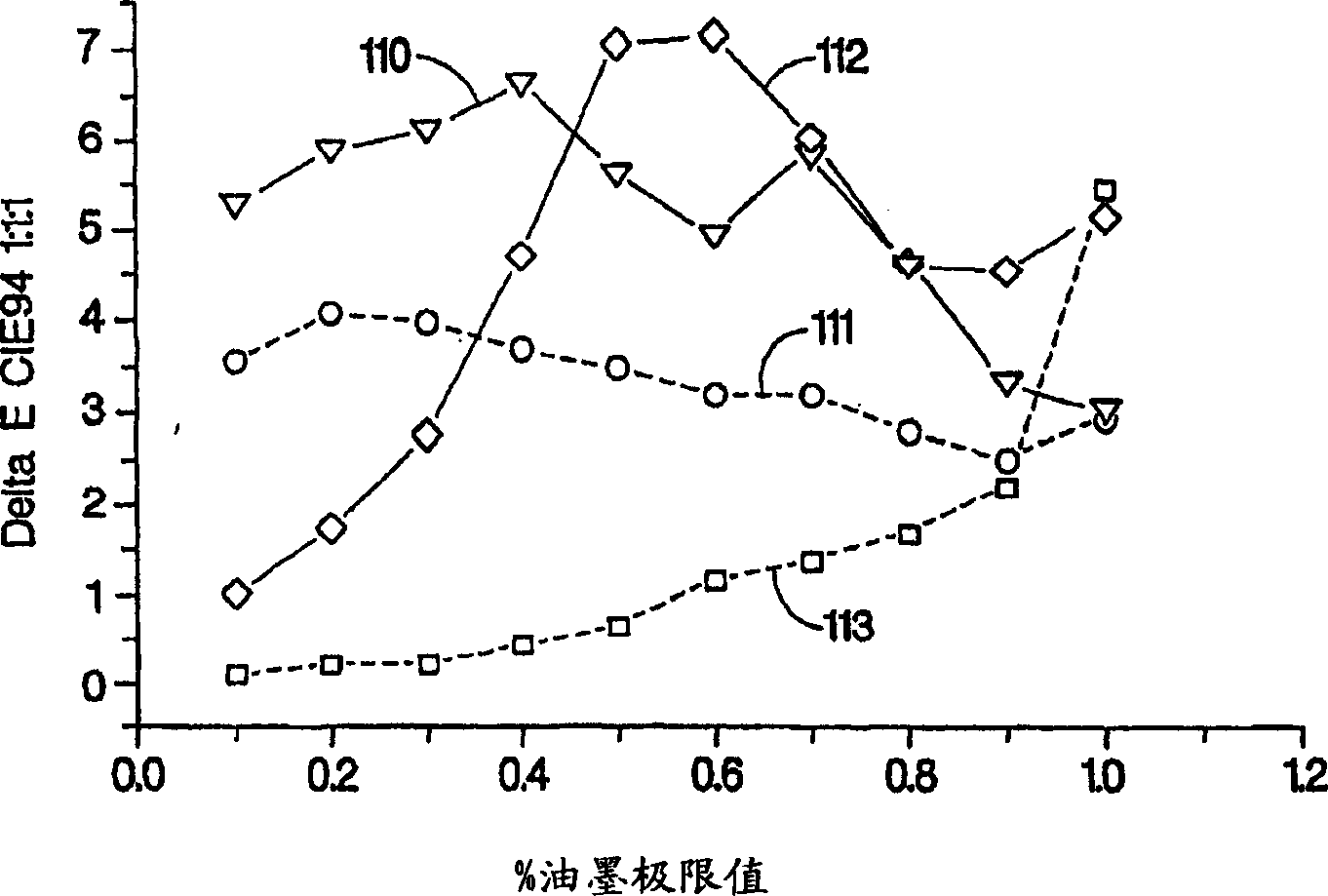

[0083] CmpK 6-ink (CMYcmK), CmpK 8-ink (CMYcmgGz), SkinTones 6-ink (CMYcmK) and Skin Tones 8-ink (CMYcmgGz) were printed on HPPremium Plus Glossy Media at 35°C and 80% relative humidity Wet hue shift was measured after 4 days. Such as figure 1 As shown, the Y-axis is Delta E CIE94 1:1:1 and the X-axis is the % ink limit value (1 is 100% ink limit value) plotted, showing curves 110 (SkinTones 6-ink), 111 (Skin Tones 8-ink), 112 (CmpK 6-ink) and 113 (CmpK 8-ink). Delta E uses the CIE94 method to measure color difference. This is a technique that simulates how human vision responds to light reflected from a smooth surface. A Delta E approximates the smallest color difference that a human can distinguish under good to ideal lighting conditions. Therefore, a change below 2 units means that color difference is difficult to perceive. This figure shows that the gray ink of the present invention prints the neutral zone (CmpK 8-ink) and the skin tone (Skin Tones 8-ink) compared to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com