Antifalse packaging bottle

A technology for anti-counterfeiting packaging and bottle caps, which is applied in the directions of packaging, transportation and packaging, and devices for preventing repeated loading of containers, etc., which can solve the problem that the anti-counterfeiting effect is not ideal, and achieve the effect of good anti-counterfeiting performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

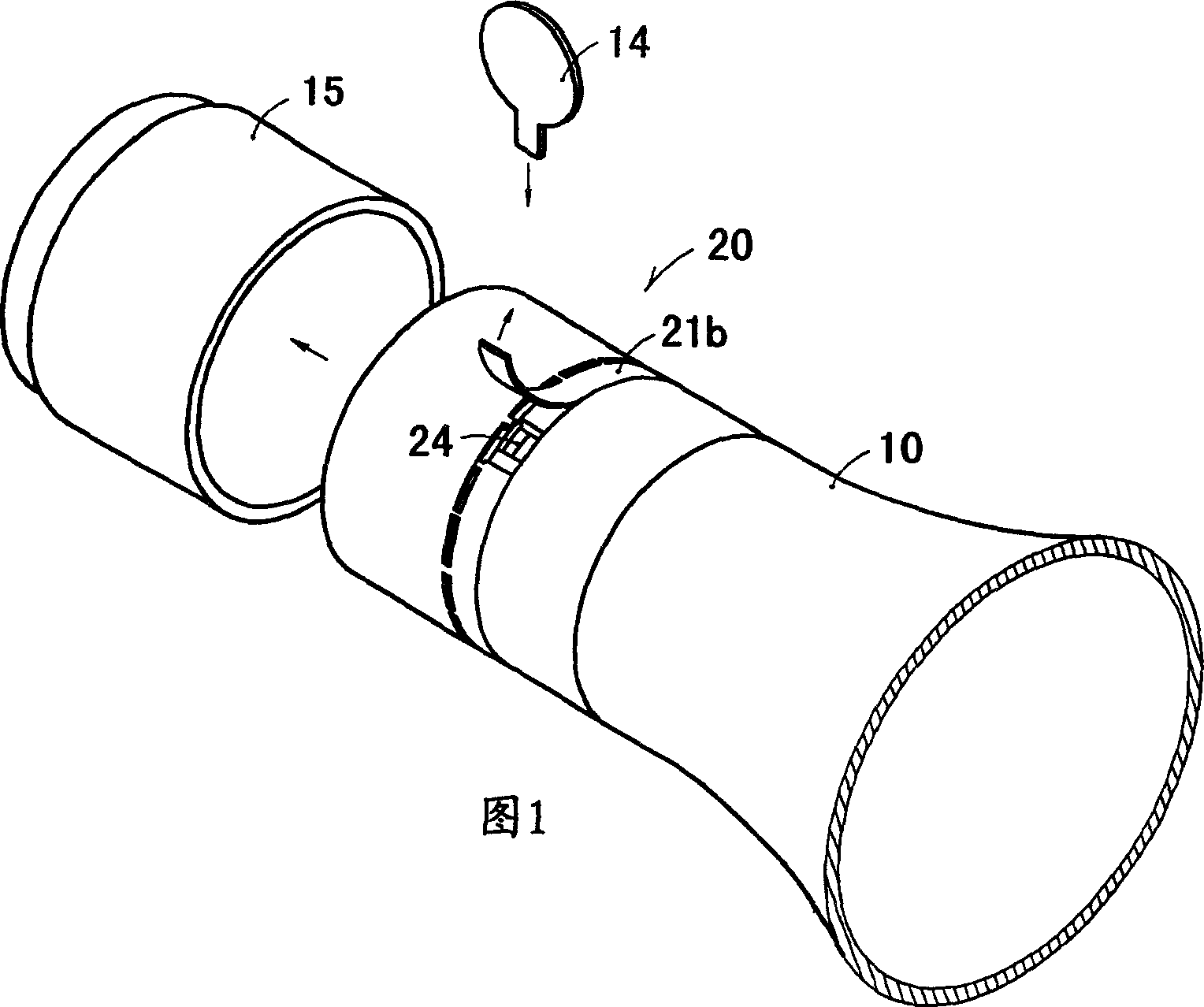

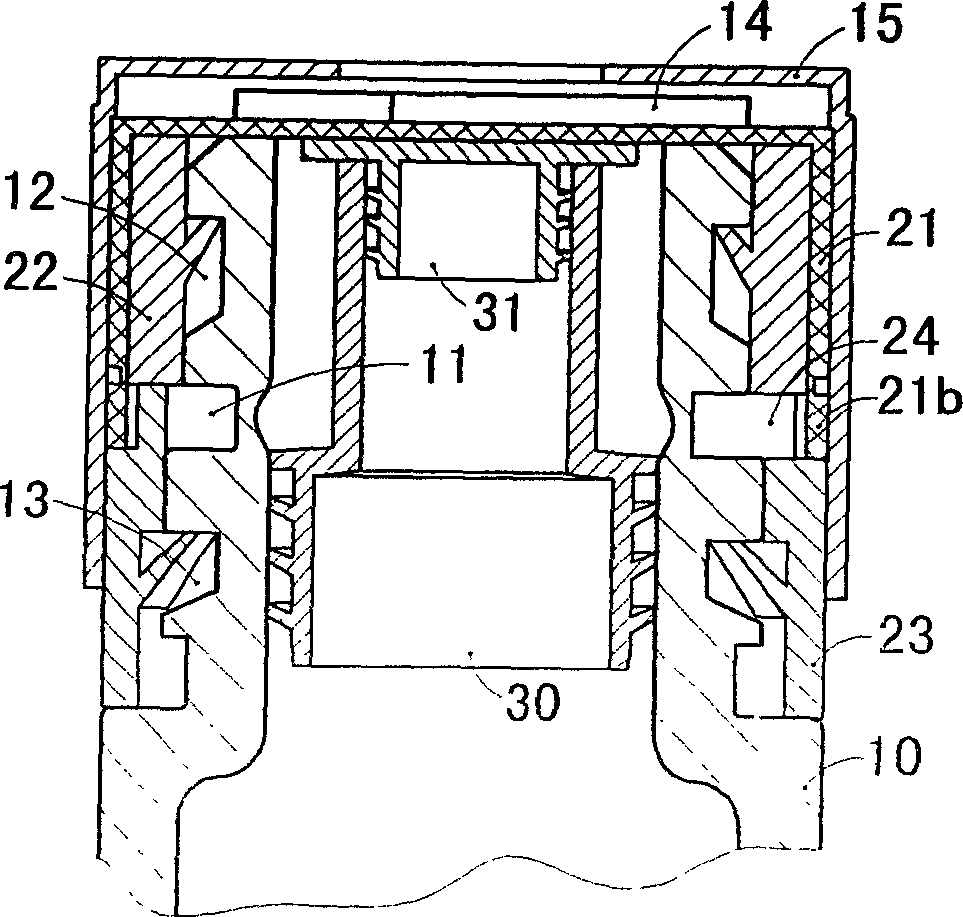

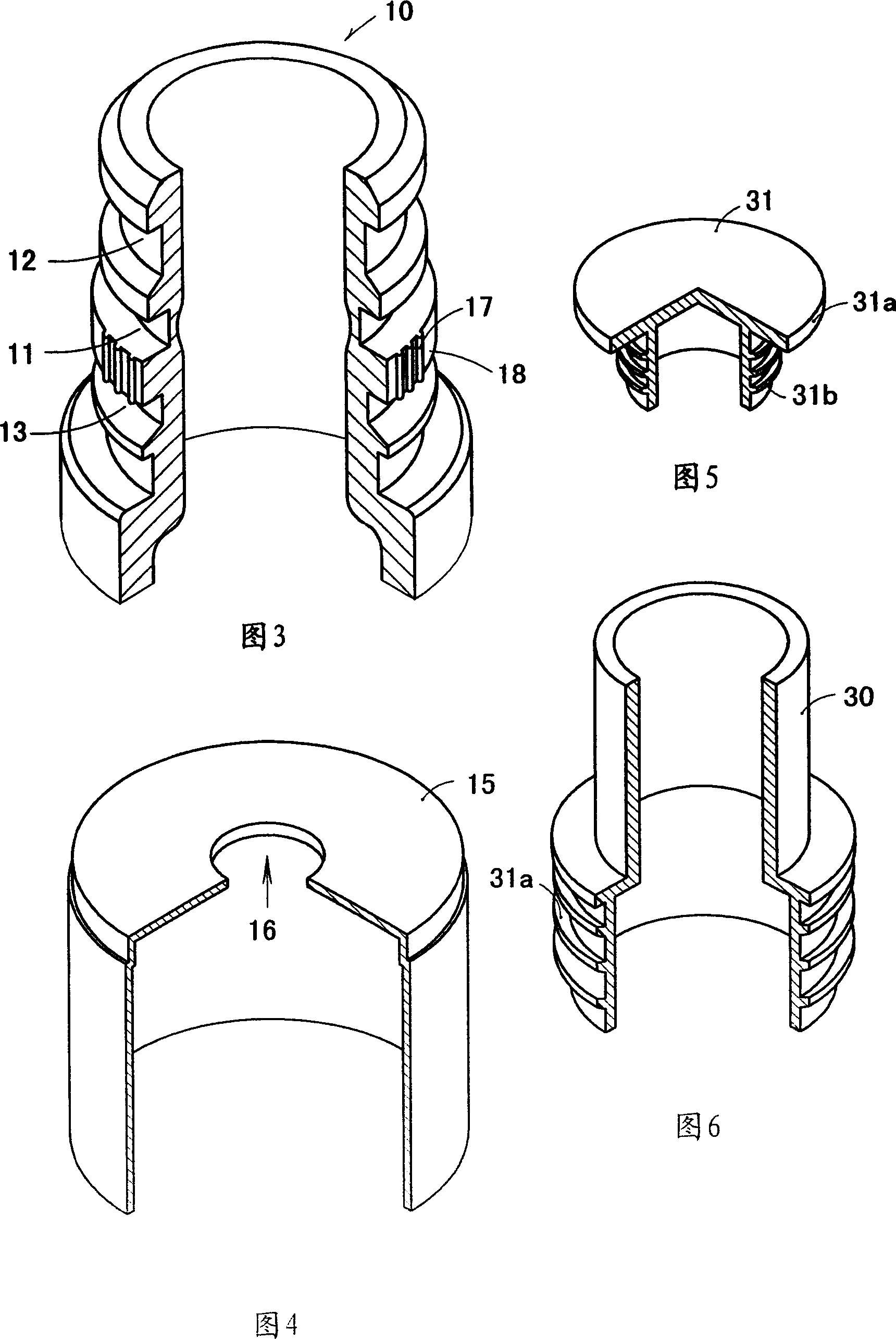

[0026] As shown in FIG. 1 , the anti-counterfeit packaging bottle of the present invention includes a bottle body and a bottle cap 20 , and the bottle cap 20 is plugged and fixed on the neck 10 of the bottle body. As shown in FIG. 3 , a thinning groove 11 is opened on the bottleneck 10 . Figure 1, figure 2 As shown, the bottle cap 20 is provided with at least one opening gap 24 opposite to the thinning groove 11 , and the bottle cap 20 is composed of an upper part and a lower part which are detachably butted along the circumferential direction of the thinning groove 11 . The bottle neck 10 can be easily broken off from the thinning groove 11 by the opening device 14, so that the bottleneck part is broken and separated from the bottle body, and the packaging bottle can only be opened after this part is broken off, so that the bottle body can only be use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com