Movable contact unit and panel switch using same

A technology of moving contact and contact body, which is used in electrical switches, moving contacts, metal foil contacts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, embodiments of the present invention will be described using the drawings.

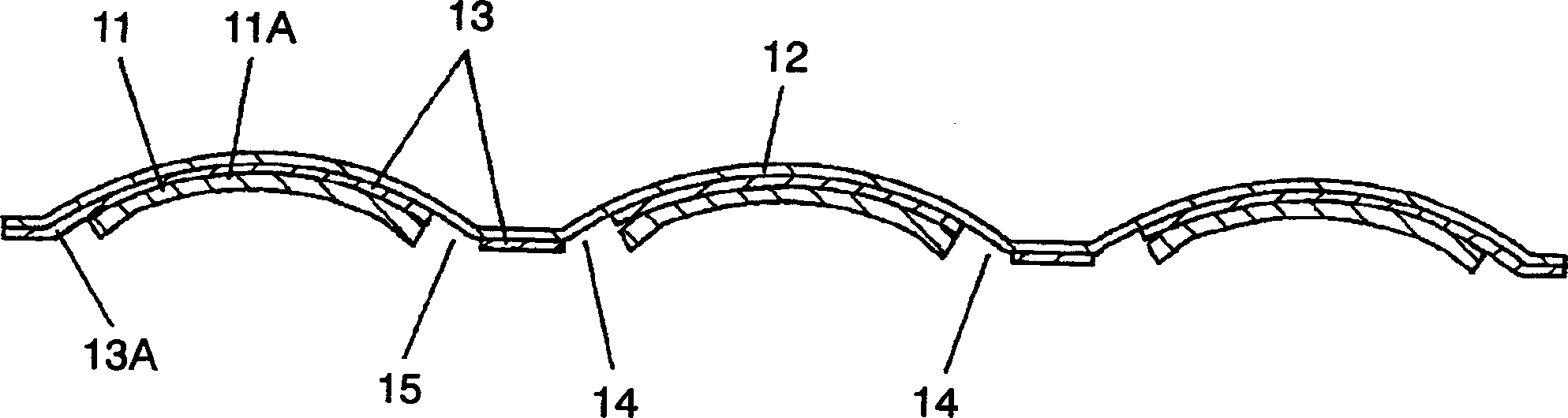

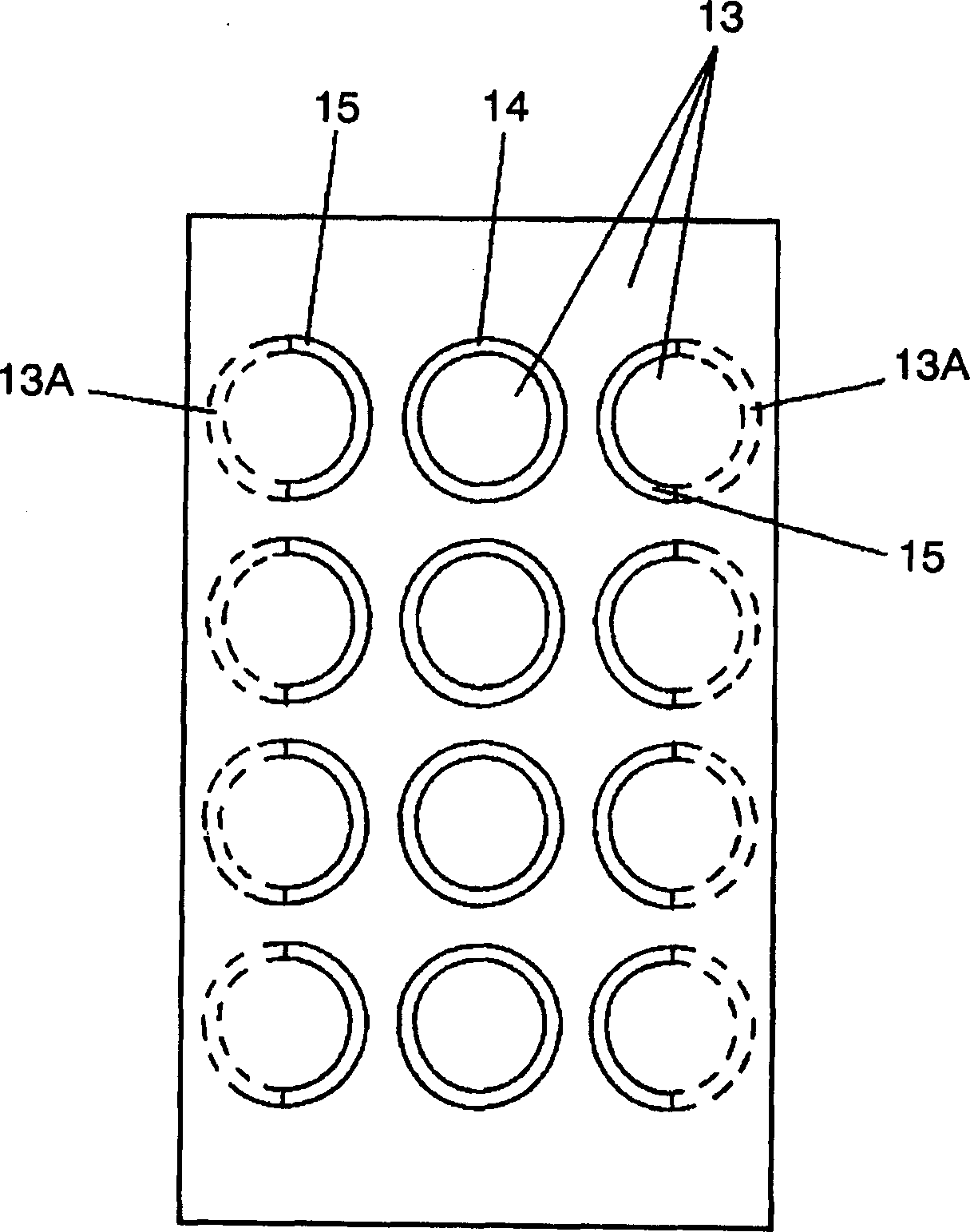

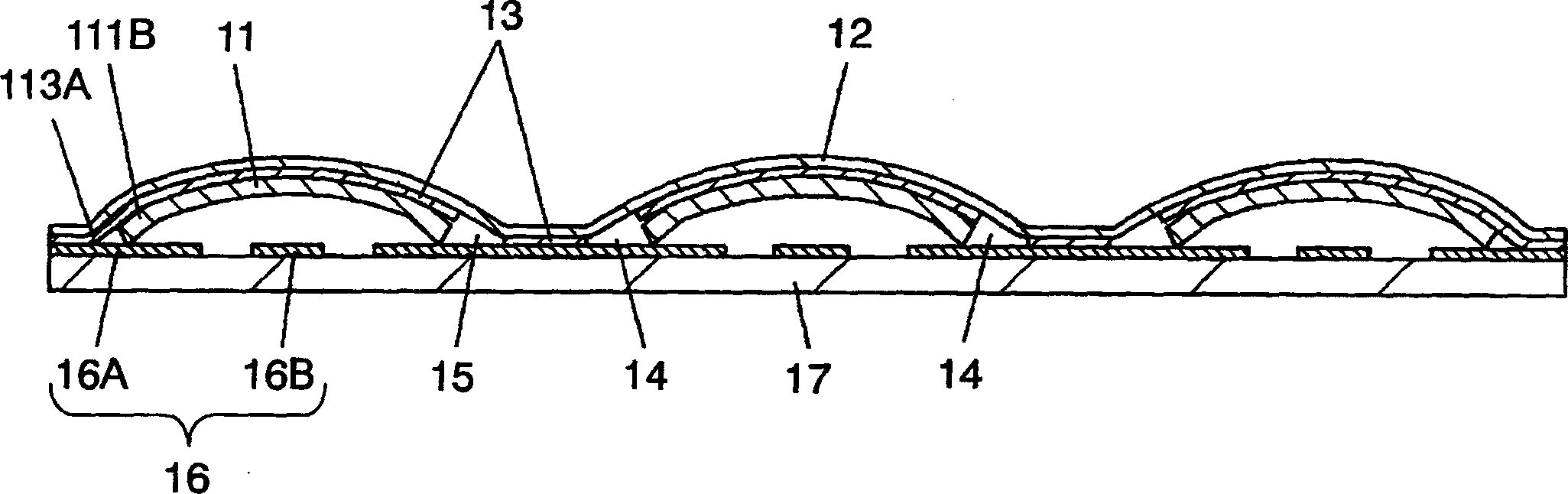

[0025] figure 1 is a sectional view of a movable contact body according to an embodiment of the present invention, figure 2 is a view of the lower surface of the substrate.

[0026] Such as figure 1 as well as figure 2 As shown, the movable contact body includes a movable contact 11 and a substrate 12 . The movable contact 11 is made of an elastic thin metal plate. The movable contact 11 is the same as the conventional structure, and its outer shape is circular, and the lower part is open, and the upper part is convex. The substrate 12 is made of an insulating film. The adhesive 13 is applied by printing on almost the entire lower surface of the substrate 12 . The upper surface of the dome-shaped apex portion 11A of each movable contact 11 is adhered and held with an adhesive 13 . A plurality of movable contacts 11 are arranged at predetermined positions on the substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com