Swinging discharge device of industrial furnace

A technology of discharging device and industrial furnace, applied in furnaces, furnace components, lighting and heating equipment, etc., can solve the problems of high equipment failure rate, high energy consumption, low calcination efficiency, etc., and achieve high combustion efficiency and energy saving. , the effect of temperature stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the present invention will be further described in conjunction with the accompanying drawings. This embodiment is used to illustrate the present invention, but not to limit the present invention in any way.

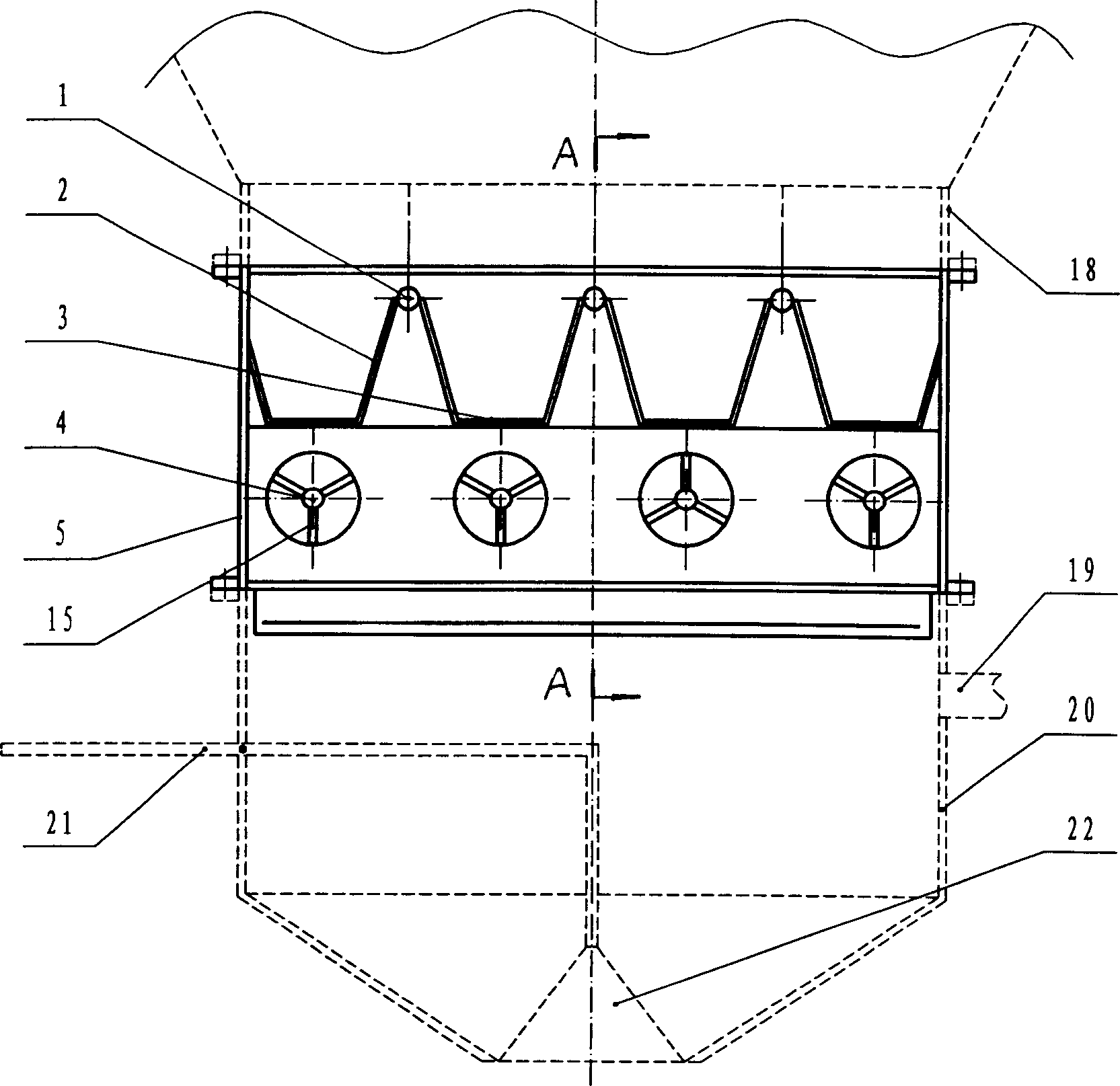

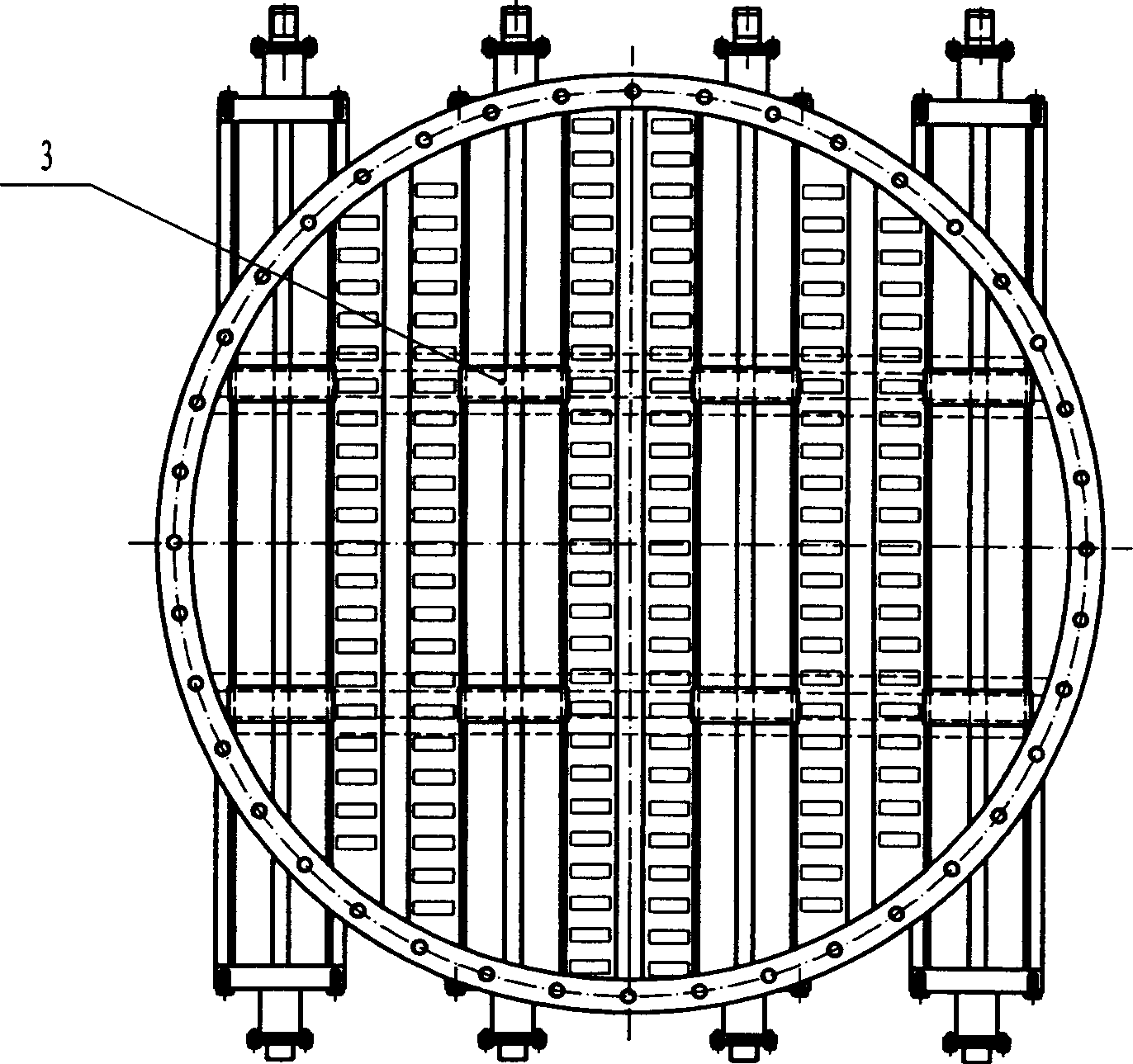

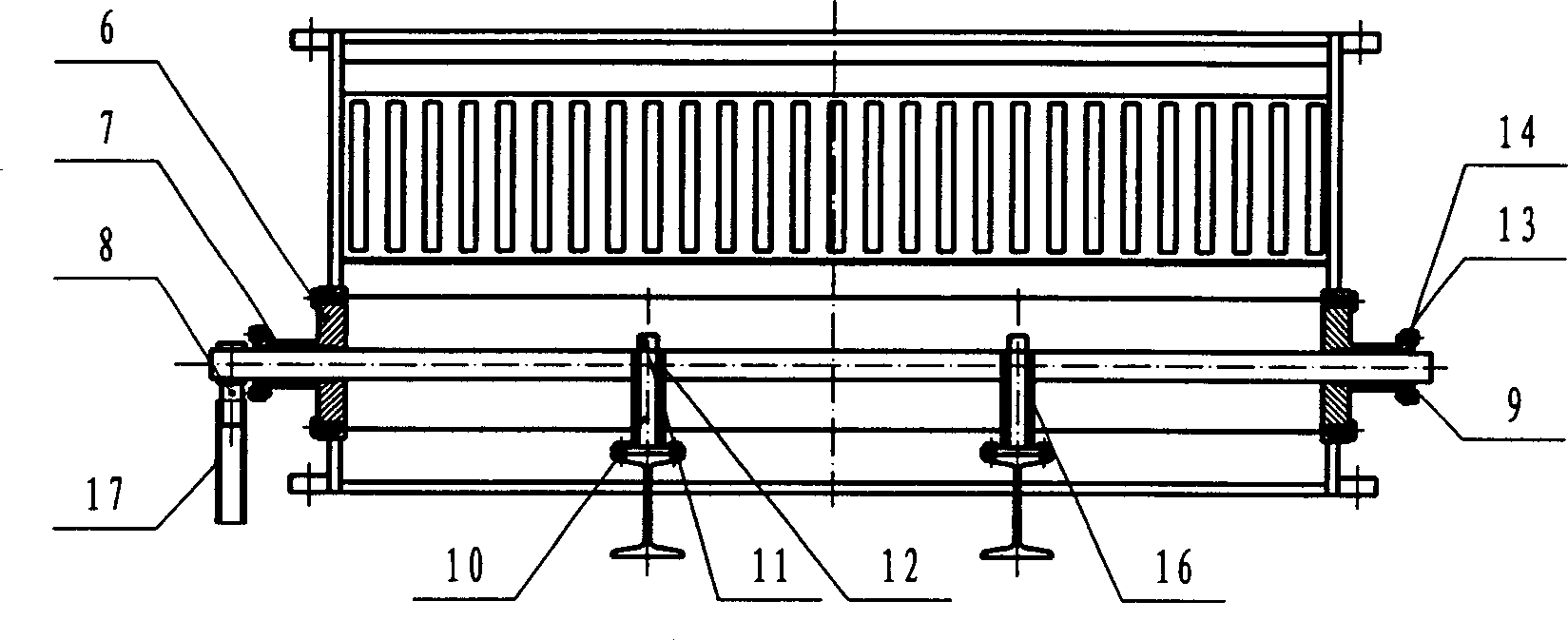

[0017] Swing-type industrial furnace discharge device, including the upper part connected with the furnace body 18, the lower part connected with the bell-shaped hopper 20 shell 5, the shell 5 is equipped with a combination of porous air distribution board 2, fixed distance partition 3 connected cloth The lower end of wind plate 2. At least one group of air distribution plates 2 is arranged in the shell 5, the cross section of the combination of air distribution plates 2 is inverted trapezoidal, and the upper ends of adjacent combined air distribution plates 2 are welded and fixedly connected by round steel 1. The number of spacer partitions 3 is at least two, and each spacer partition 3 is spaced apart from each other. The round steel 1 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com