Variable focal lens

一种变焦透镜、透镜的技术,应用在变焦透镜领域,能够解决不会提供、不能确信使用者等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

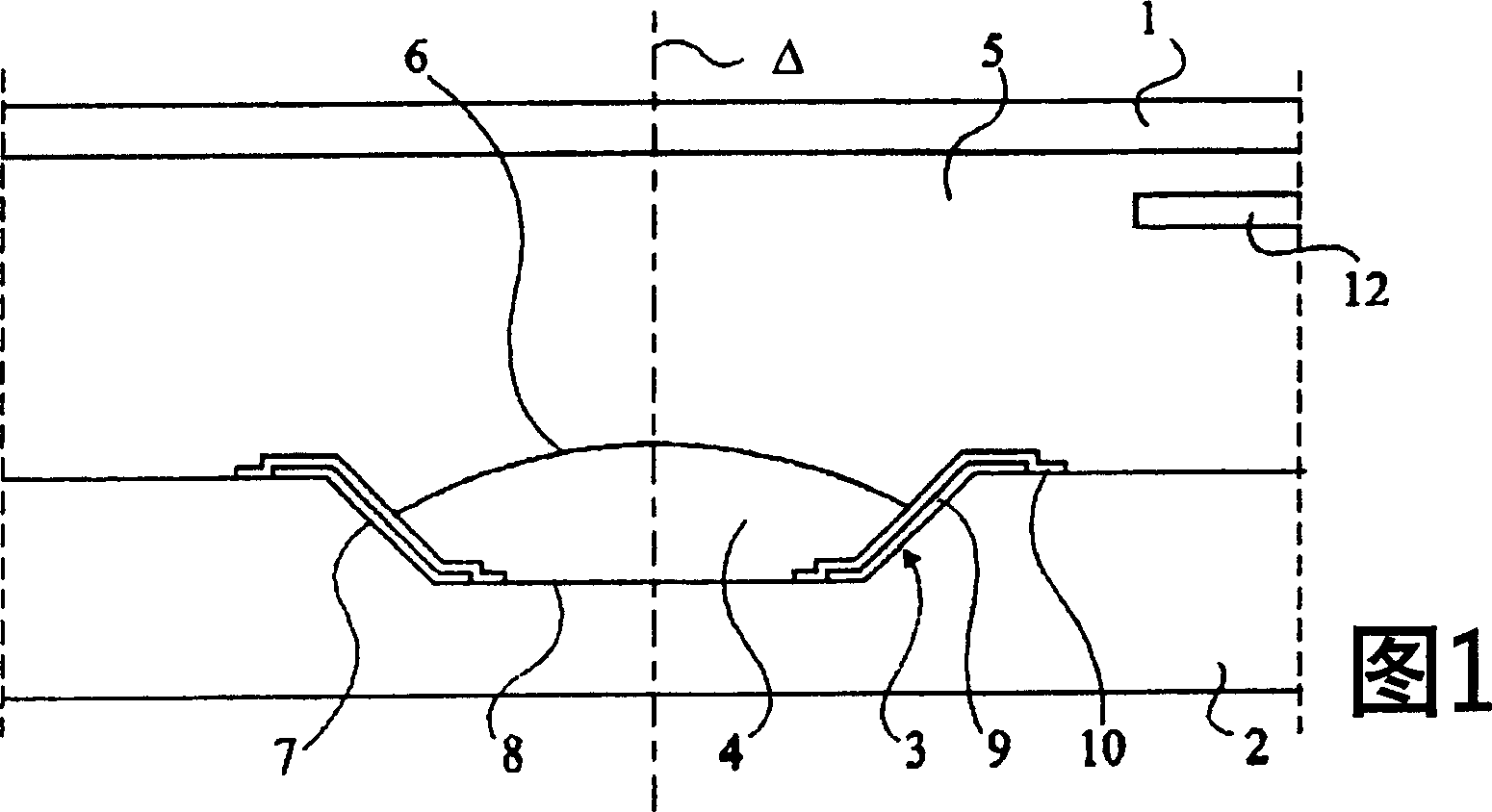

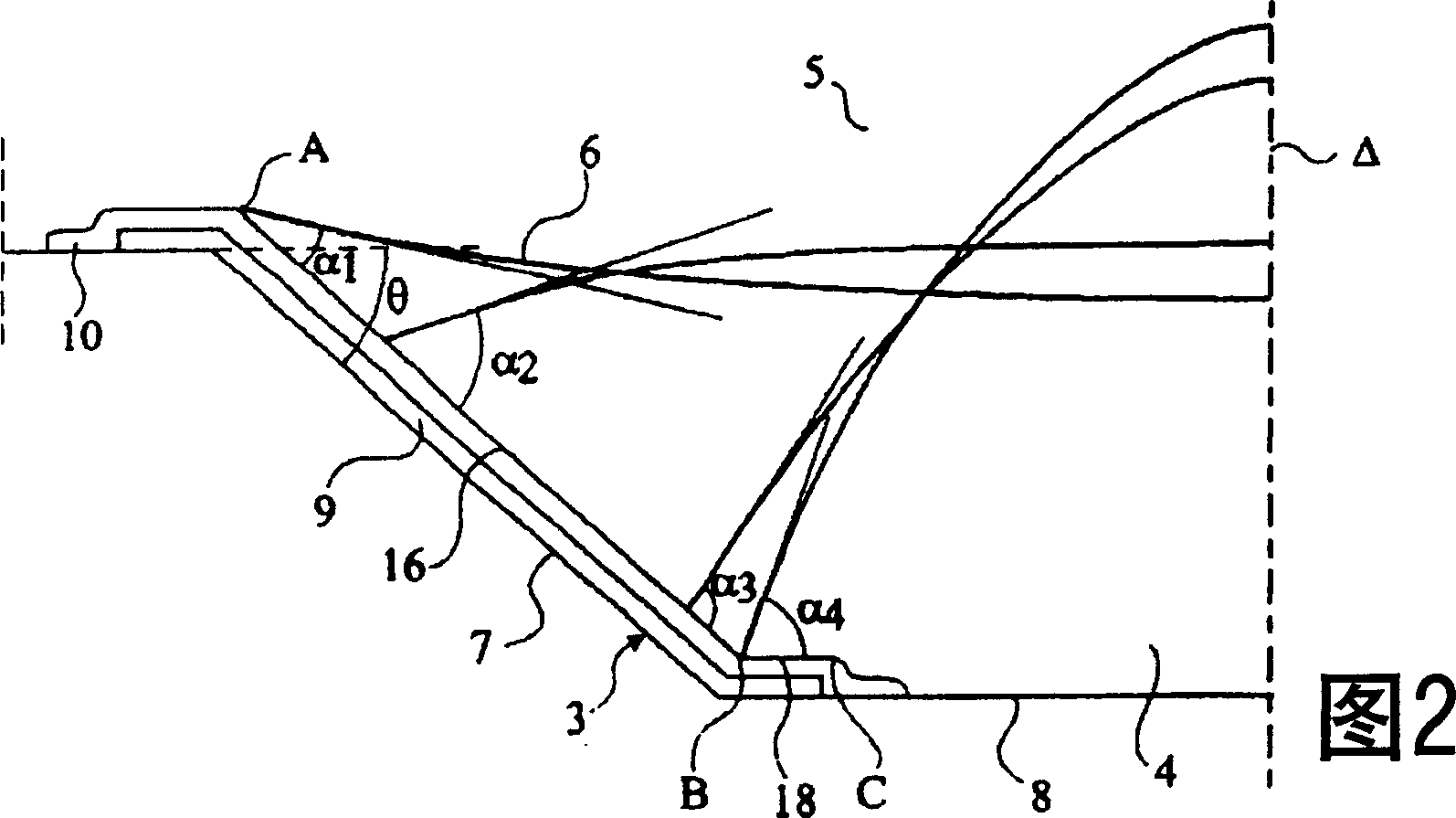

[0035]The invention consists in providing an intermediate surface between the conical surface 7 and the base 8 of the recess 3, wherein, in a plane containing the optical axis Δ of the lens, at the connection zone between the conical surface and the intermediate surface, perpendicular to the The angle between the plane of the optical axis and the tangent plane of this midplane is larger than the angle between the plane perpendicular to the optical axis and the cone, or the angle between the plane perpendicular to the optical axis Δ and the cone increases rapidly when moving away from the junction zone . The electrode 9 then extends over the conical surface 7 and the intermediate surface and, if necessary, over a part of the base 8 . The shape of the outer surface of the insulating layer 10 covering the electrode 9 replicates the shape of the notch 3 . As a result, the shell that moves the periphery of the deformable refractive surface 6 along its walls comprises: an upper par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com