Exterior structure for keyboard instrument

A technology for external structures and keyboard instruments, applied in stringed instruments, automatic musical instruments, instruments, etc., can solve problems such as increasing mold costs, reducing screw fastening rigidity, and upper shell design restrictions, achieving the effect of increasing types and reducing mold costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

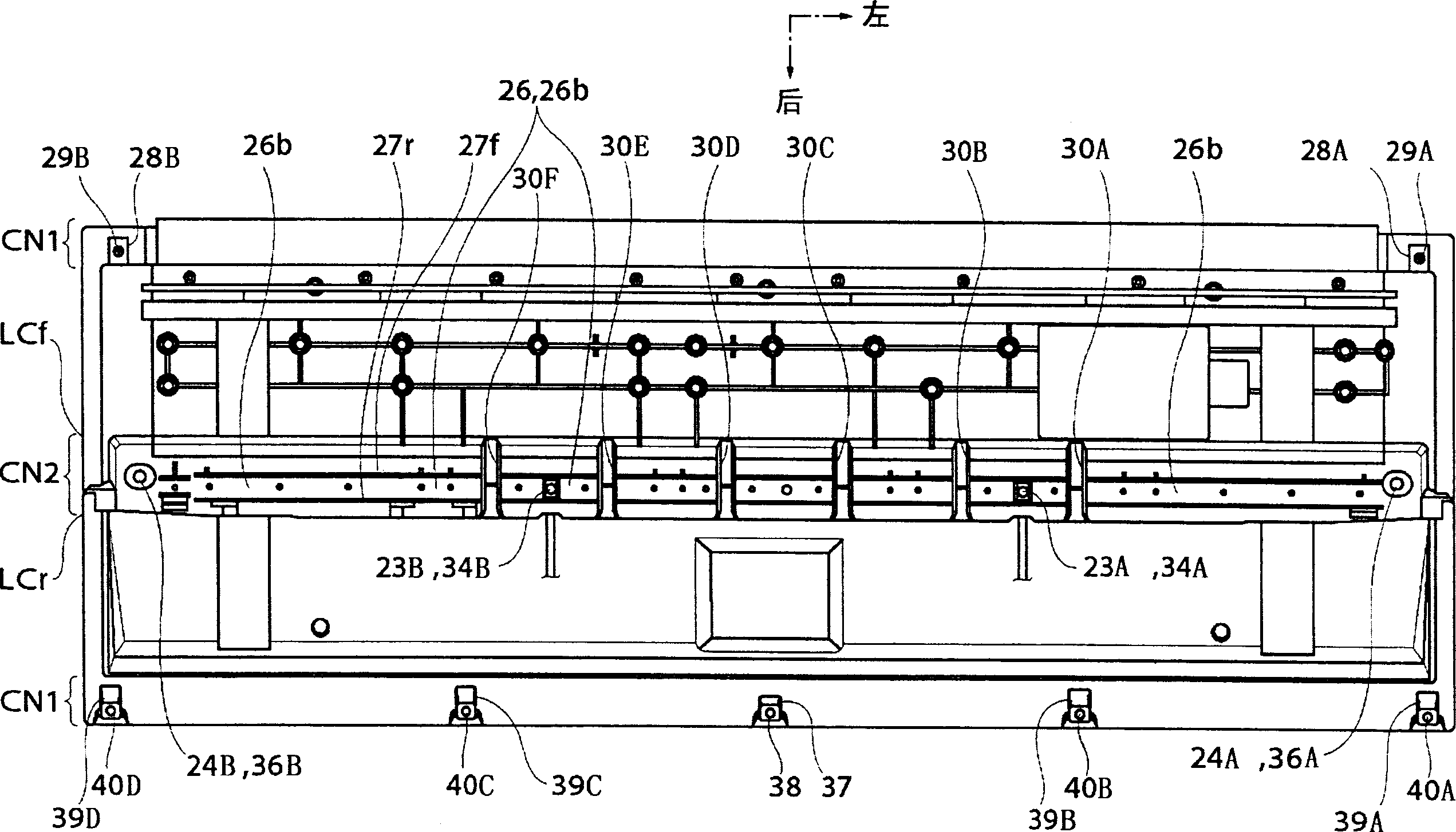

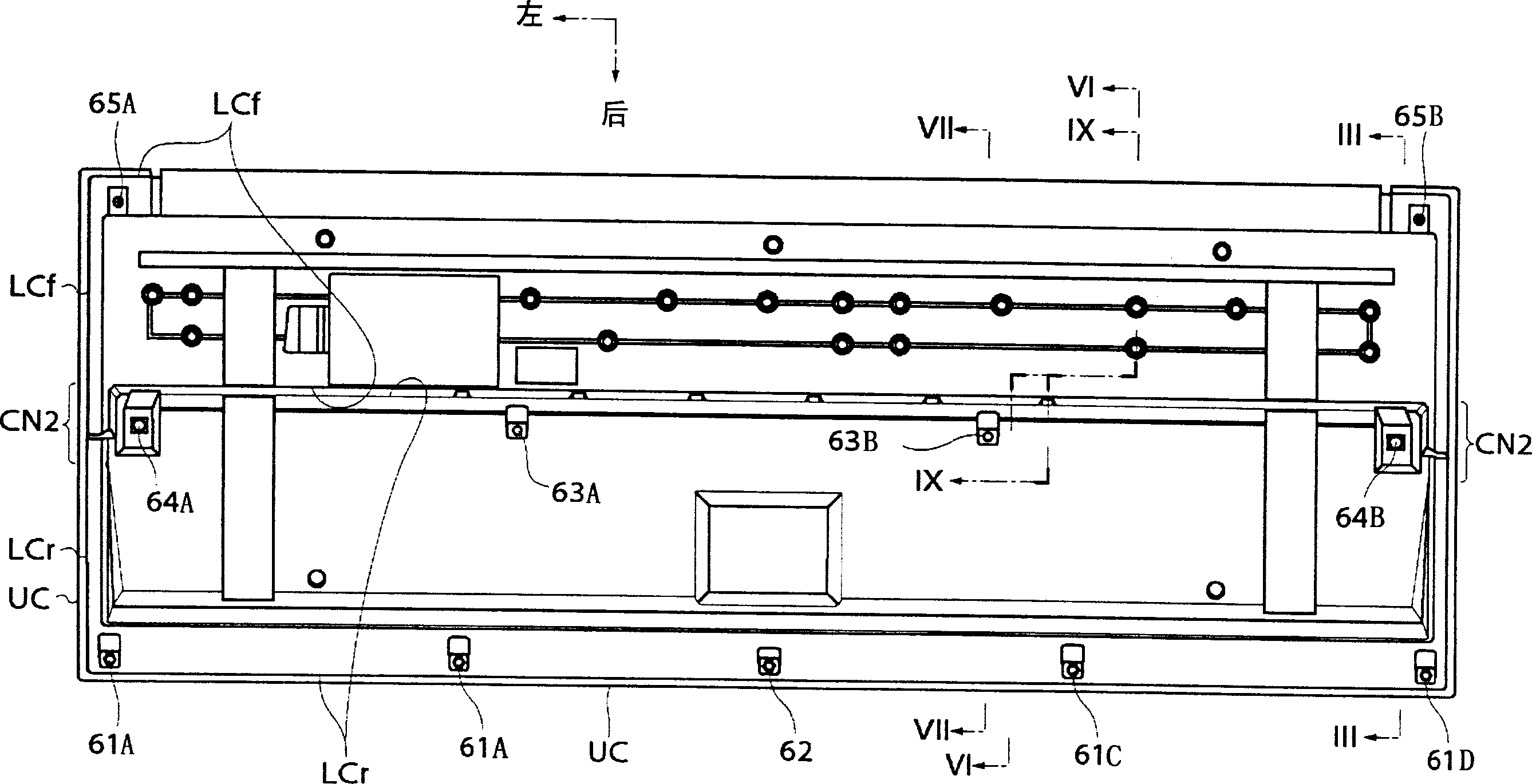

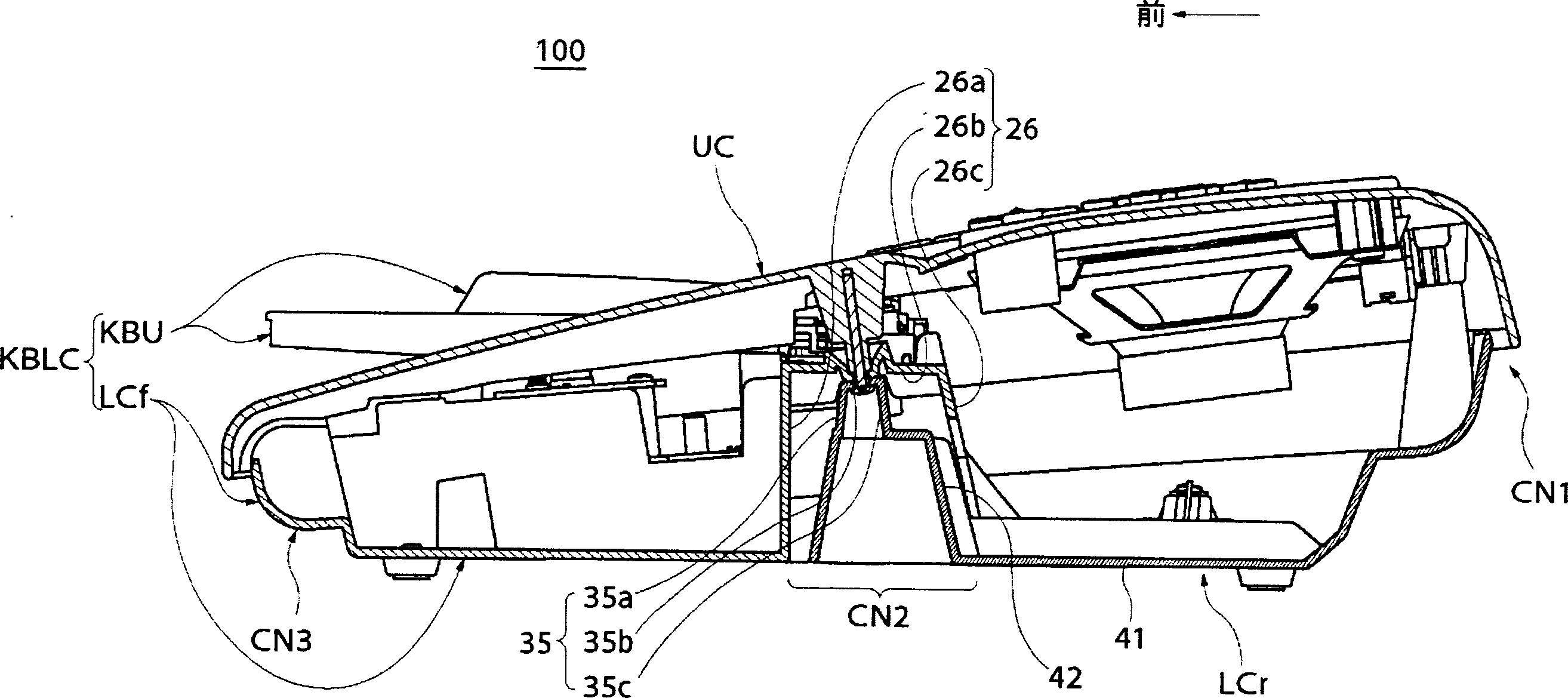

[0054] figure 1 For a plan view of a first keyboard musical instrument employing an external structure in an embodiment of the present invention, the keyboard member and the upper case are removed. figure 2 It is a bottom view of the first keyboard instrument. image 3 for along figure 2 Sectional view of line III-III.

[0055] Such as image 3 As shown, according to the external structure of the present embodiment, the keyboard instrument 100 is constituted by assembling the keyboard unit KBU, the front lower case LCf, the upper case UC, and the rear lower case LCr, all made of resin. Hereinafter, an assembly formed by assembling the keyboard unit KBU and the front lower case LCf is referred to as "keyboard-assembled front lower case KBLC". Also, an assembly formed by assembling the front lower case LCf, the upper case UC, and the rear lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com