Grooved surface belt or roll and method of fabrication

A manufacturing method and belt technology, applied in the field of papermaking, can solve problems such as complex manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

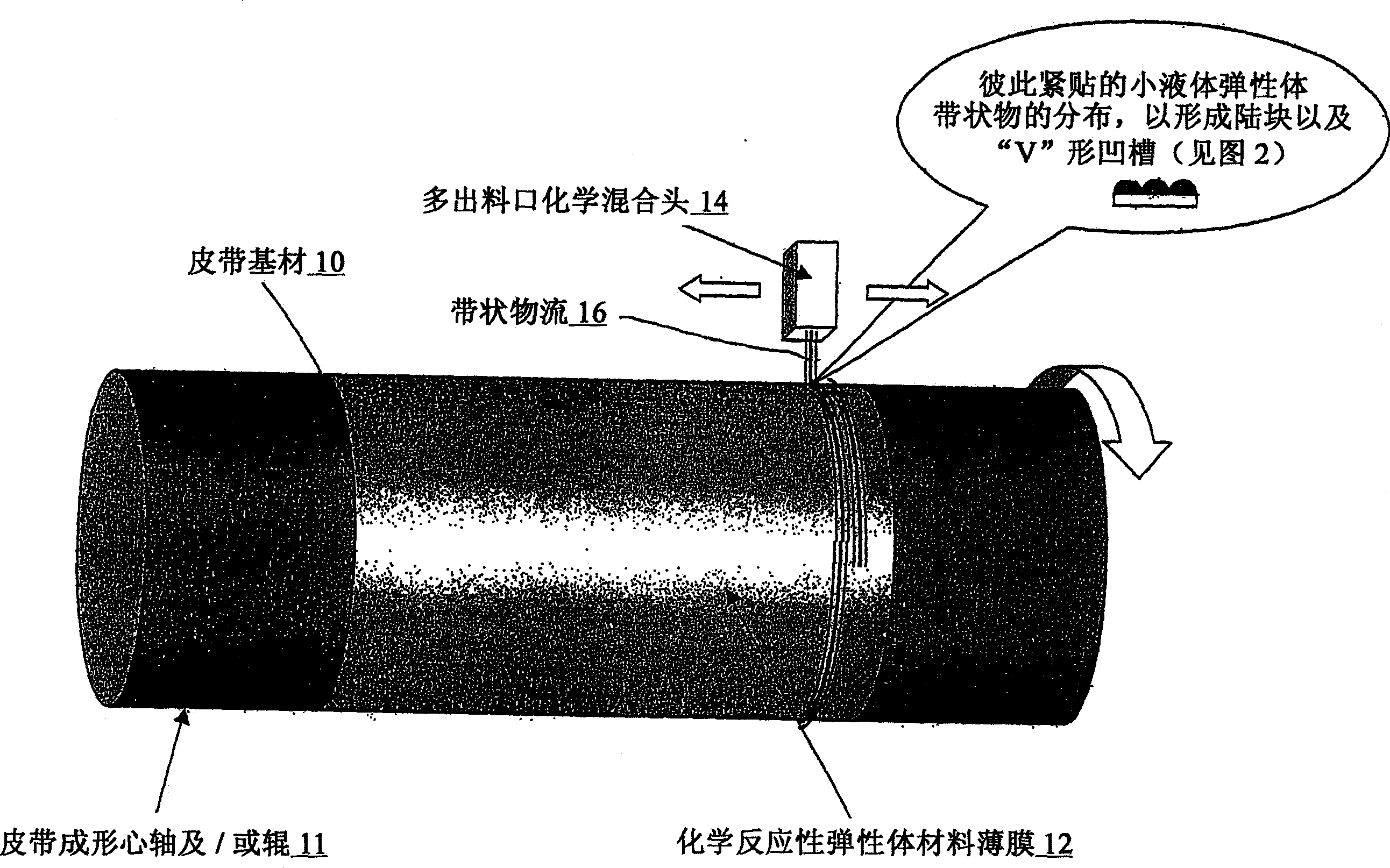

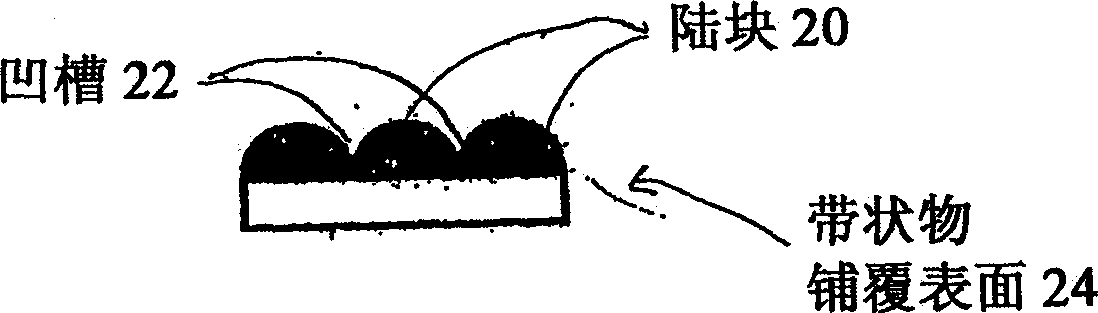

[0027] A preferred embodiment of the present invention as shown in Fig. 1 will now be described with respect to the manufacture of a shoe press belt for a paper machine and its manufacturing procedure. However, it should be noted that the present invention is also suitable for use in the manufacture of paper machine rolls or roll covers.

[0028] With continued reference to FIG. 1 , the belt may comprise a base structure or substrate of any conventional belt base substrate known in the art, including wovens, nonwovens, spiral connections, arrays of MD or CD yarns, knitted fabrics, Extruded mesh, and helically wound strips of woven and nonwoven materials. These substrates may comprise any type of yarn used to make papermaker's clothing, such as monofilament yarns, plied monofilament yarns, multifilament yarns, and plied multifilament yarns. These yarns may be extruded from any polymeric resinous material available to one of ordinary skill in the art for this purpose. Thus, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com