Lubricating oil system and cooking equipment employed the same

A technology of lubricating oil system and cooking utensils, which is applied in the field of lubricating oil system and cooking equipment adopting the lubricating oil system, which can solve the problems of the quality and taste limitation of finished dishes, the limitation of stir-frying, and the inability to realize re-frying techniques, etc., and achieve the expansion The range of cooking techniques and varieties of dishes that can be prepared, and the effect of improving taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] During the cooking process, the cooking materials and oil often need to be separated after a certain cooking process in the pot for the next operation, and most dishes require the cooking materials to be lifted out of the pot for oil draining operation to completely drain the oil .

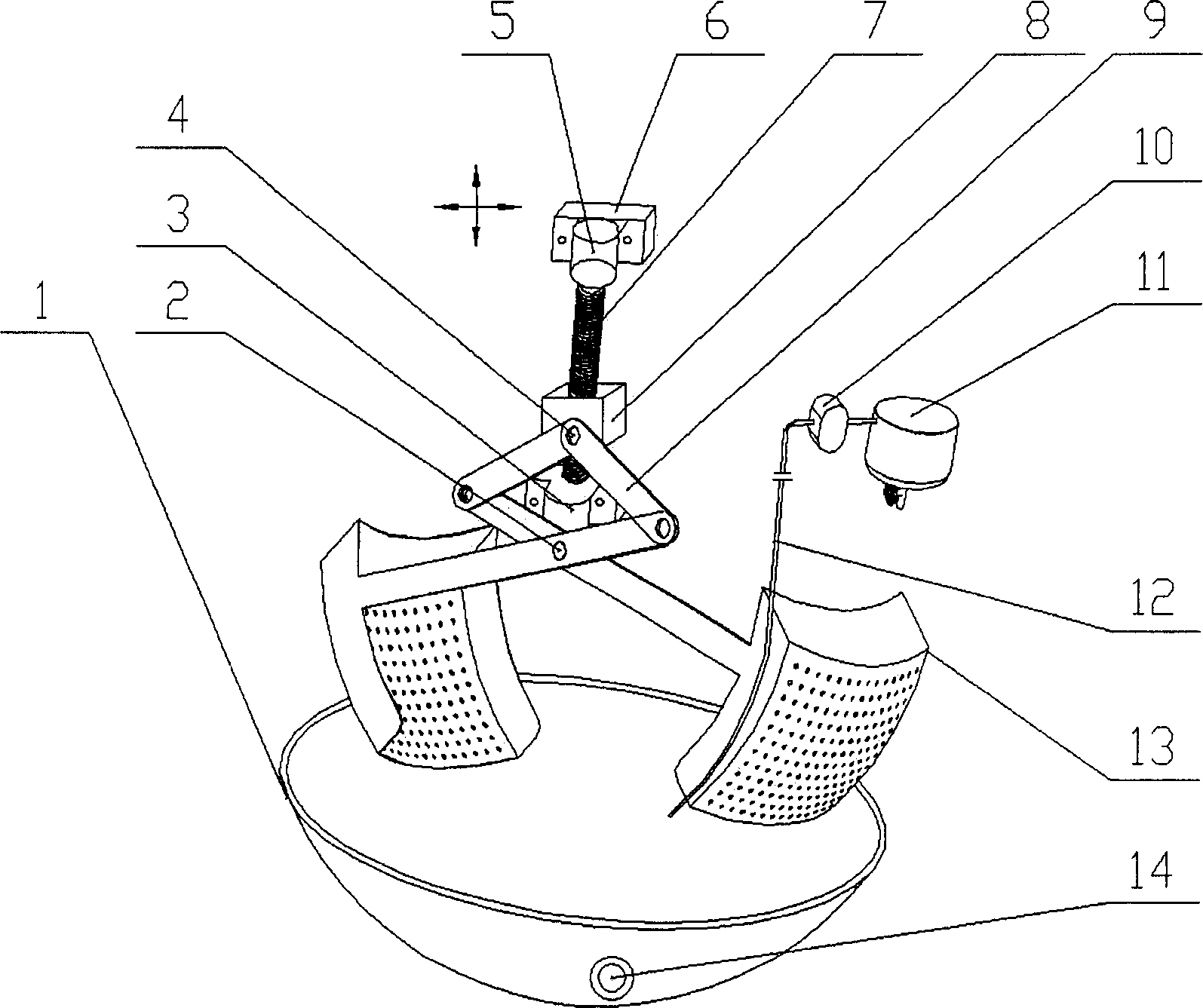

[0037] figure 1 is a schematic diagram of an embodiment of the lubricating oil system of the present invention. . This device is a kind of grasping shovel, and it comprises double folding arm linkage mechanism 9 and has the shovel-shaped tool 13 of draining hole, and whole mechanism is fixed on the host frame or mobile device by upper and lower positioning brackets 6 and 3, motor 5 The driving screw 7 rotates and drives the slider 8 to move up and down, and the double-folding arm mechanism 9 is respectively connected with the lower positioning bracket 3 and the slider 8 through the pin shafts 2 and 4. When the slider 8 moves up and down, it drives the double-folding arm linkage mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com