Fluid transfer pump

A liquid and suction port technology, which is applied in the field of pumps for liquid transportation, can solve the problem of easy retention of resist liquid and achieve good liquid replacement characteristics, low liquid retention rate, and excellent liquid replacement characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

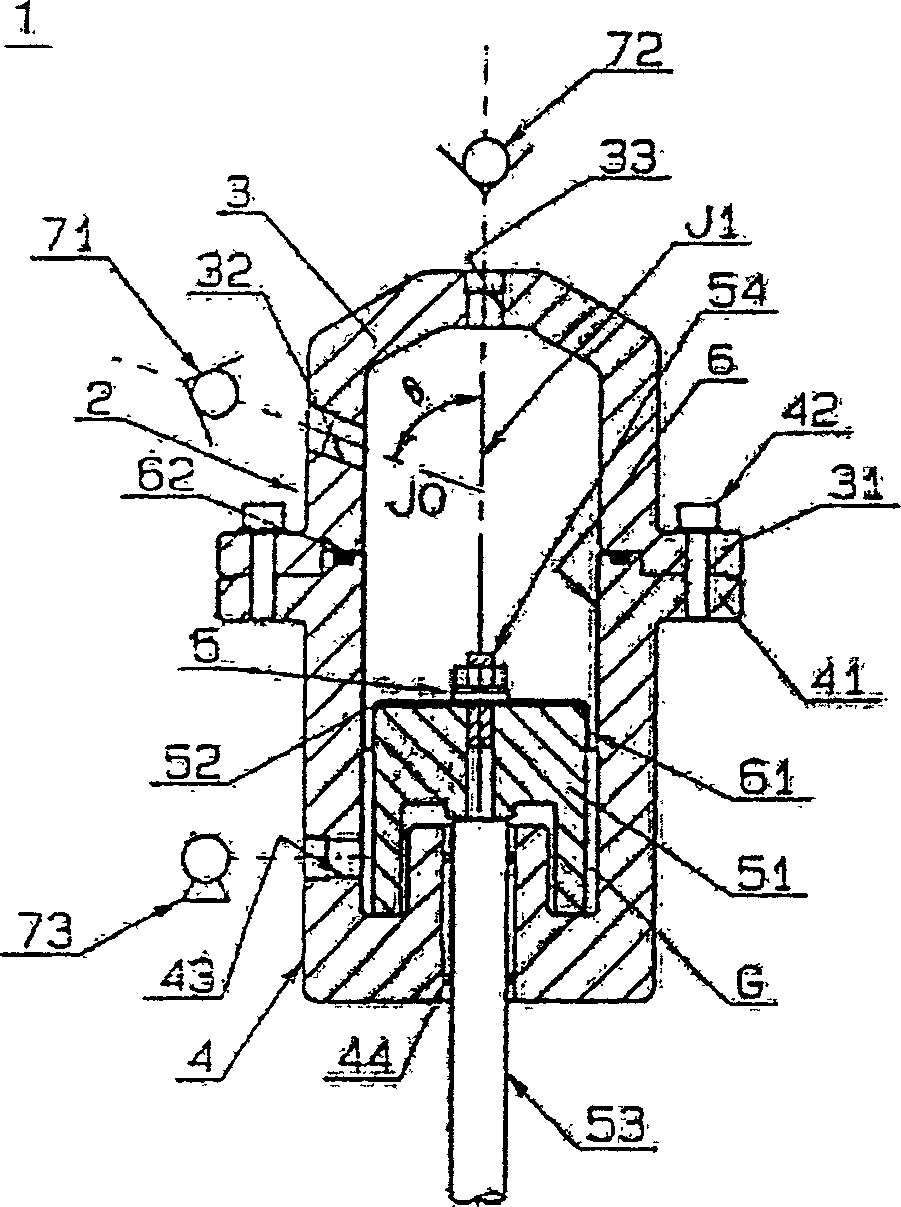

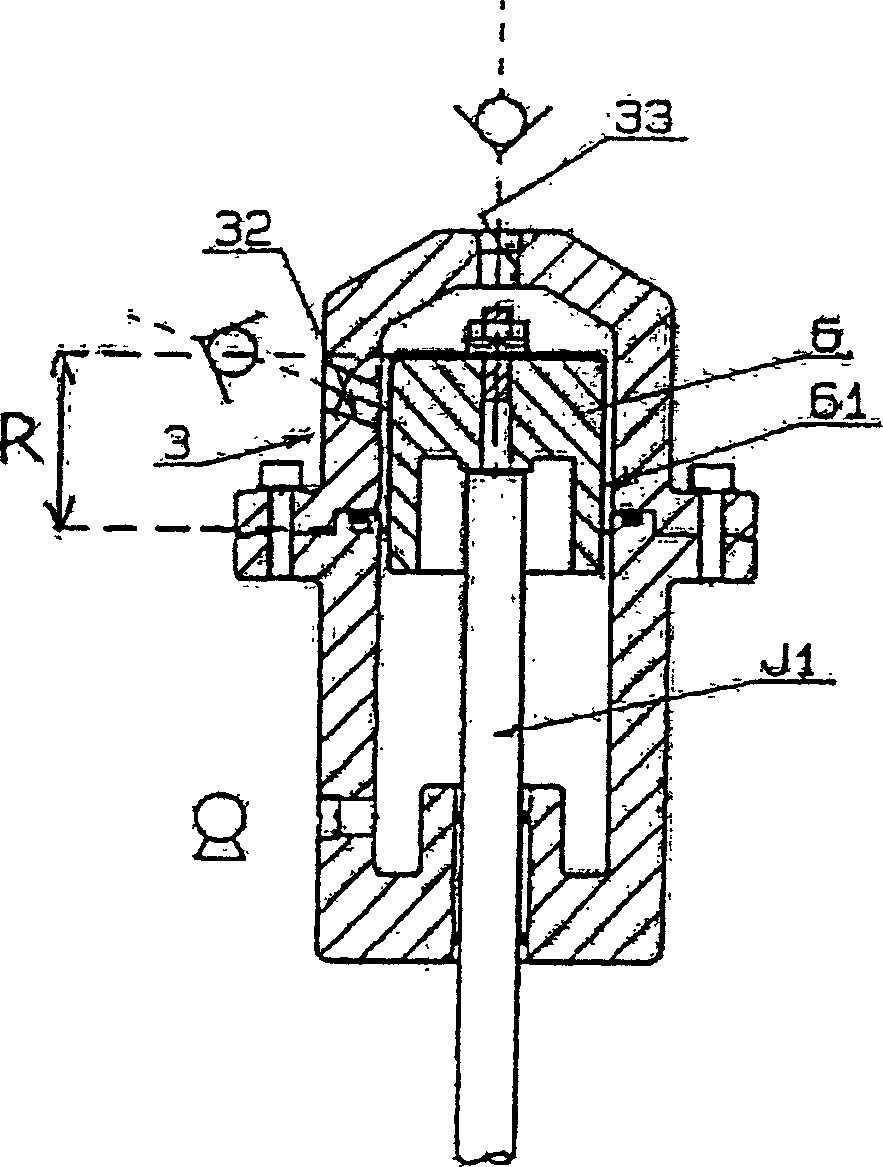

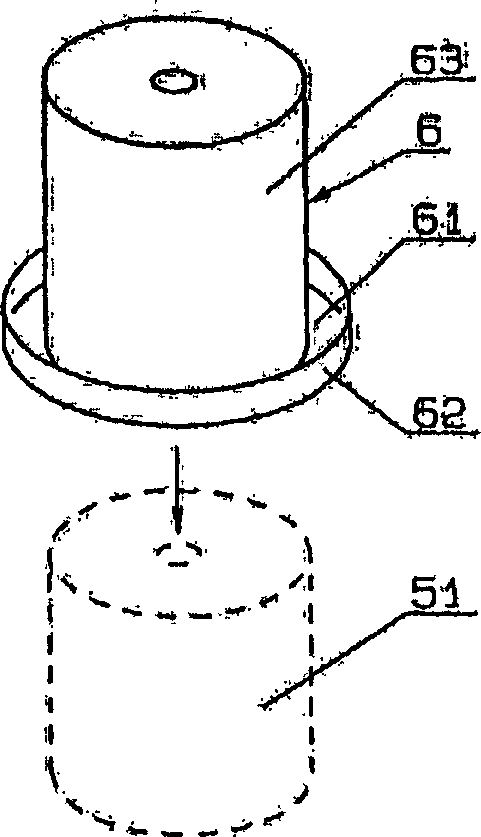

[0022] The best mode for carrying out the present invention will be described below with reference to the drawings. 1 is a front partial cross-sectional view showing a pump 1 for liquid delivery according to the present invention. FIG. 1(A) shows a state where the plunger 5 is at the bottom dead center, and FIG. 1(B) shows the state where the plunger 5 is at the top dead center. figure 2 3 is a perspective view showing the appearance of the film-shaped sealing member 6, and FIG. 3 is a partial front sectional view showing the liquid transfer pump of the present invention.

[0023] In addition, the case where the liquid is a resist liquid will be described below as an example, but of course other liquids other than the resist liquid may also be used.

[0024] As shown in FIG. 1 , a liquid transfer pump 1 according to the present invention has a cylinder 2 , a plunger 5 and a membrane seal member 6 .

[0025] The cylinder 2 includes: a substantially bowl-shaped upper cover 3 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com