Crank angle detection device and ignition timing control device for internal combustion engine

A crank angle and detection device technology, which is applied in the direction of electric spark ignition controller, engine ignition, engine control, etc., can solve the problems that the initial detonation timing of the reverse rotation of the engine cannot be avoided, and the crank angle cannot be correctly determined, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

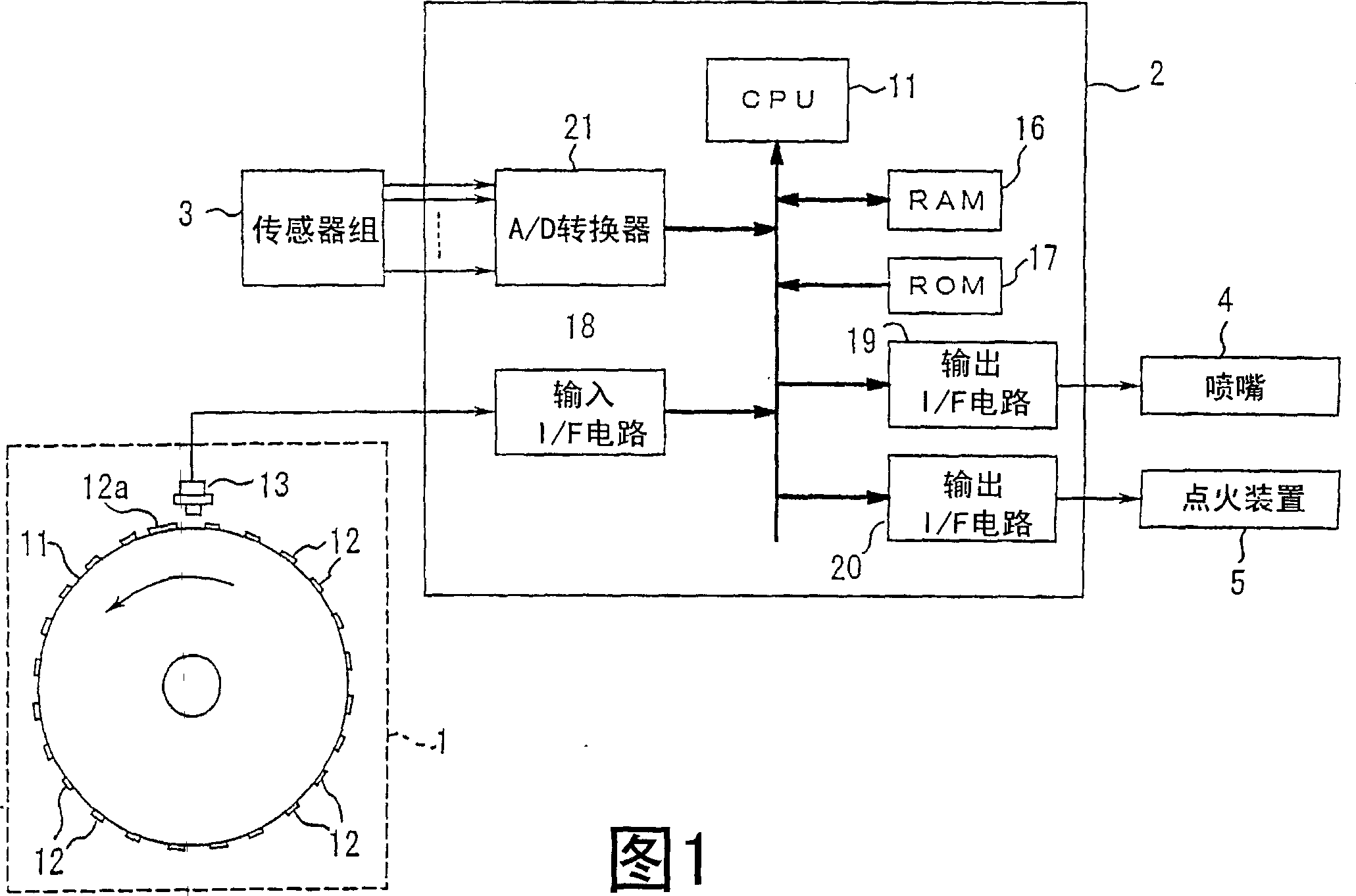

[0016] FIG. 1 shows an engine control device to which the crank angle detecting device of the present invention is applied. This engine control device includes: a crank angle detection device 1 , an ECU (Electric Control Unit: electronic control unit) 2 , a sensor group 3 , a nozzle 4 and an ignition device 5 .

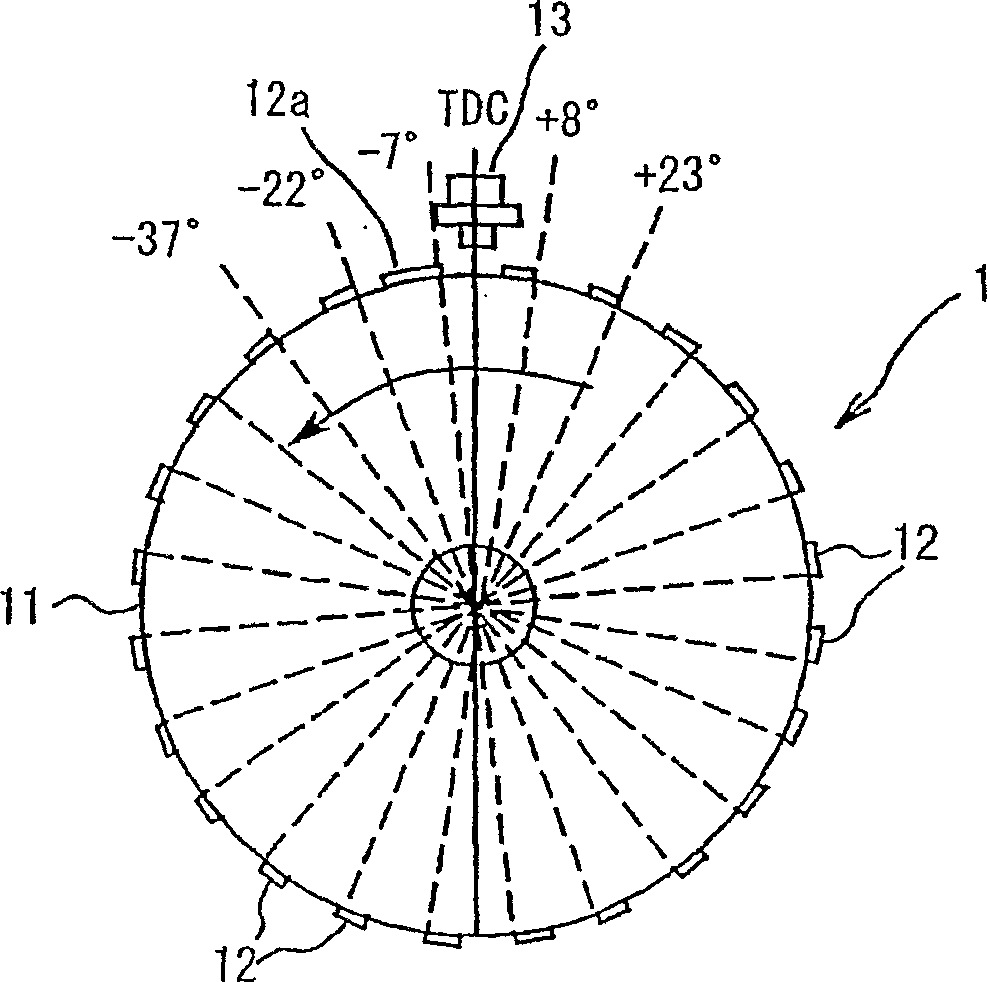

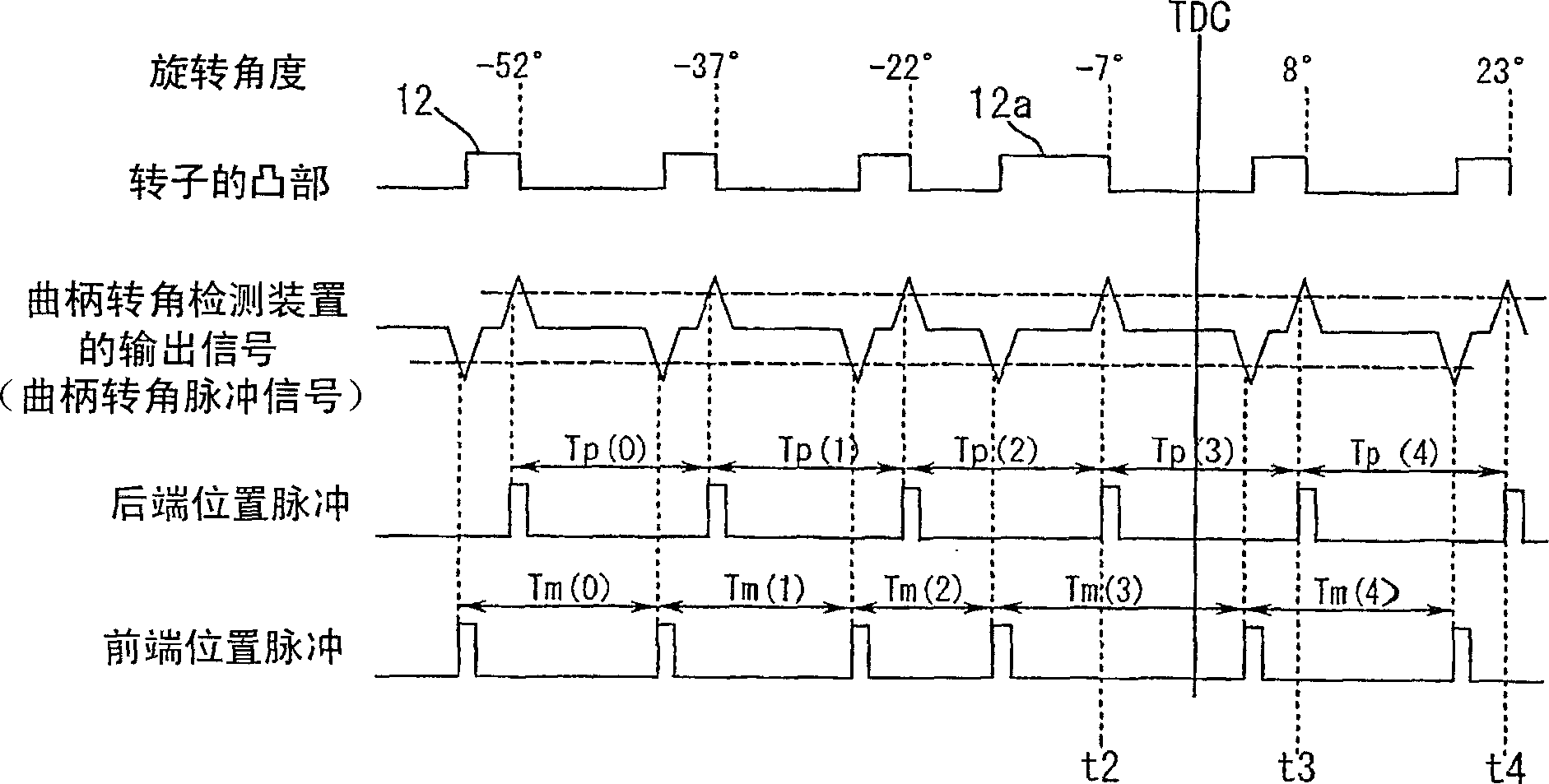

[0017] The crank angle detection device 1 includes a disc-shaped rotor 11 provided on a crankshaft (not shown) of a four-cycle internal combustion engine, and the rotor 11 rotates in conjunction with the rotation of the crankshaft. On the outer peripheral surface of the rotor 11, 24 protrusions 12 made of a magnetic material are continuously provided at intervals of 15 degrees as detected parts. An electromagnetic pickup (pickup) 13 is provided near the outer periphery of the rotor 11 . When the rotor 11 rotates, a pair of negative pulses and positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com