Rotor for laboratory centrifuges

A laboratory centrifuge and rotor technology, applied in the direction of centrifuges, etc., can solve the problems of moving the centrifuge container from the working position and the unbalanced operation of the centrifuge, and achieve the effect of reducing attention requirements, simplifying manufacturing, and improving operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In the various embodiments of the present invention shown in the figures, the same components are marked with the same reference numerals.

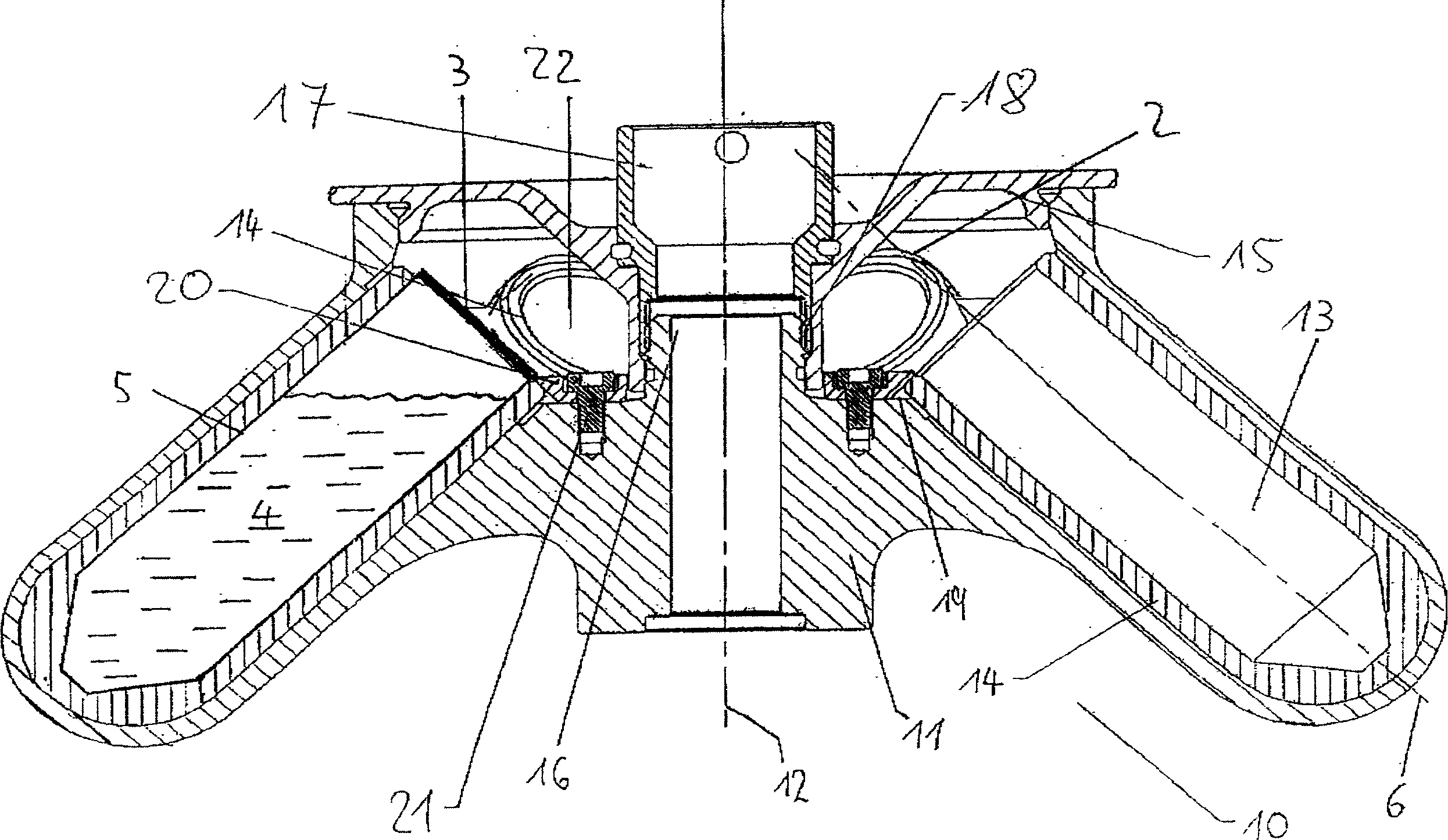

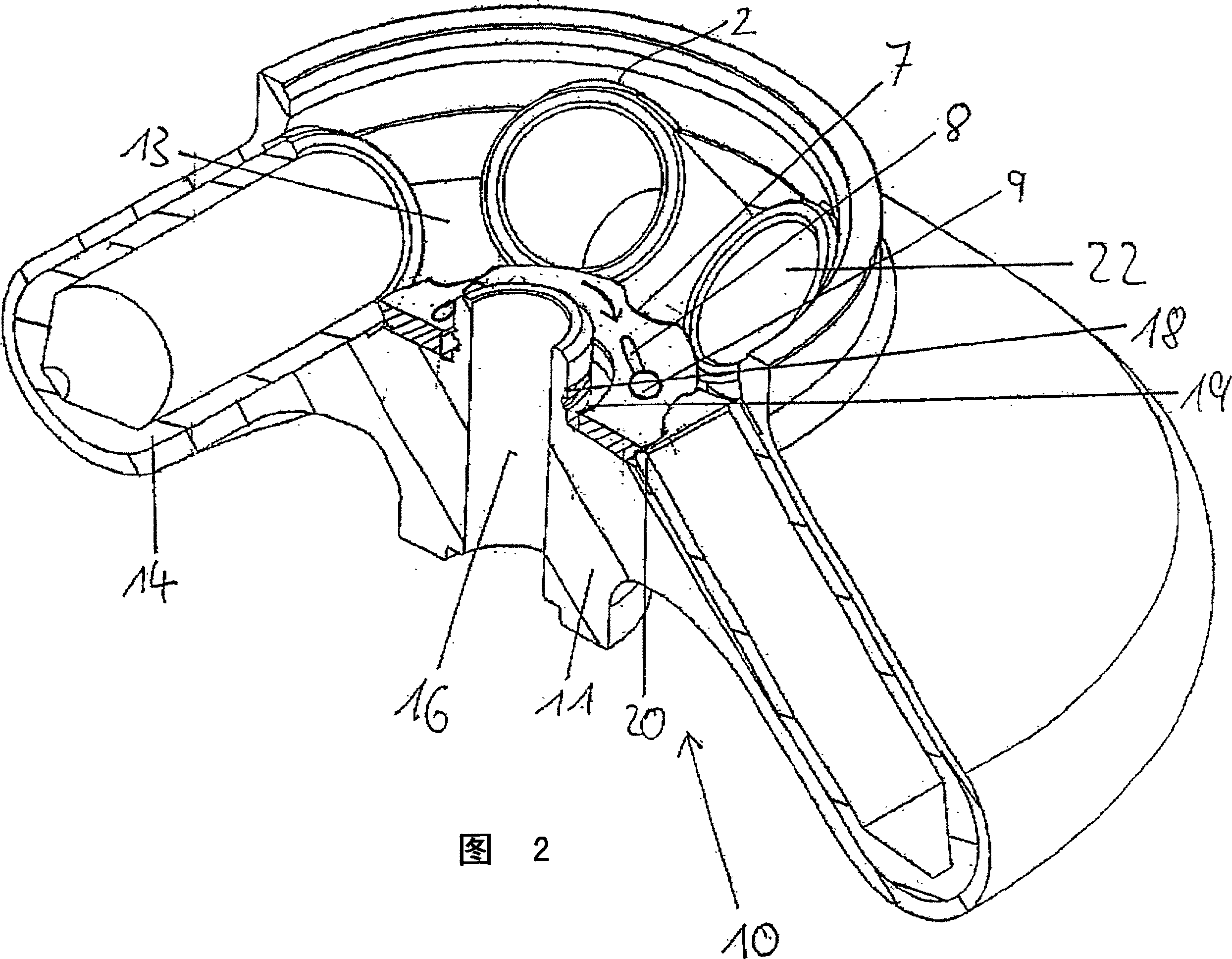

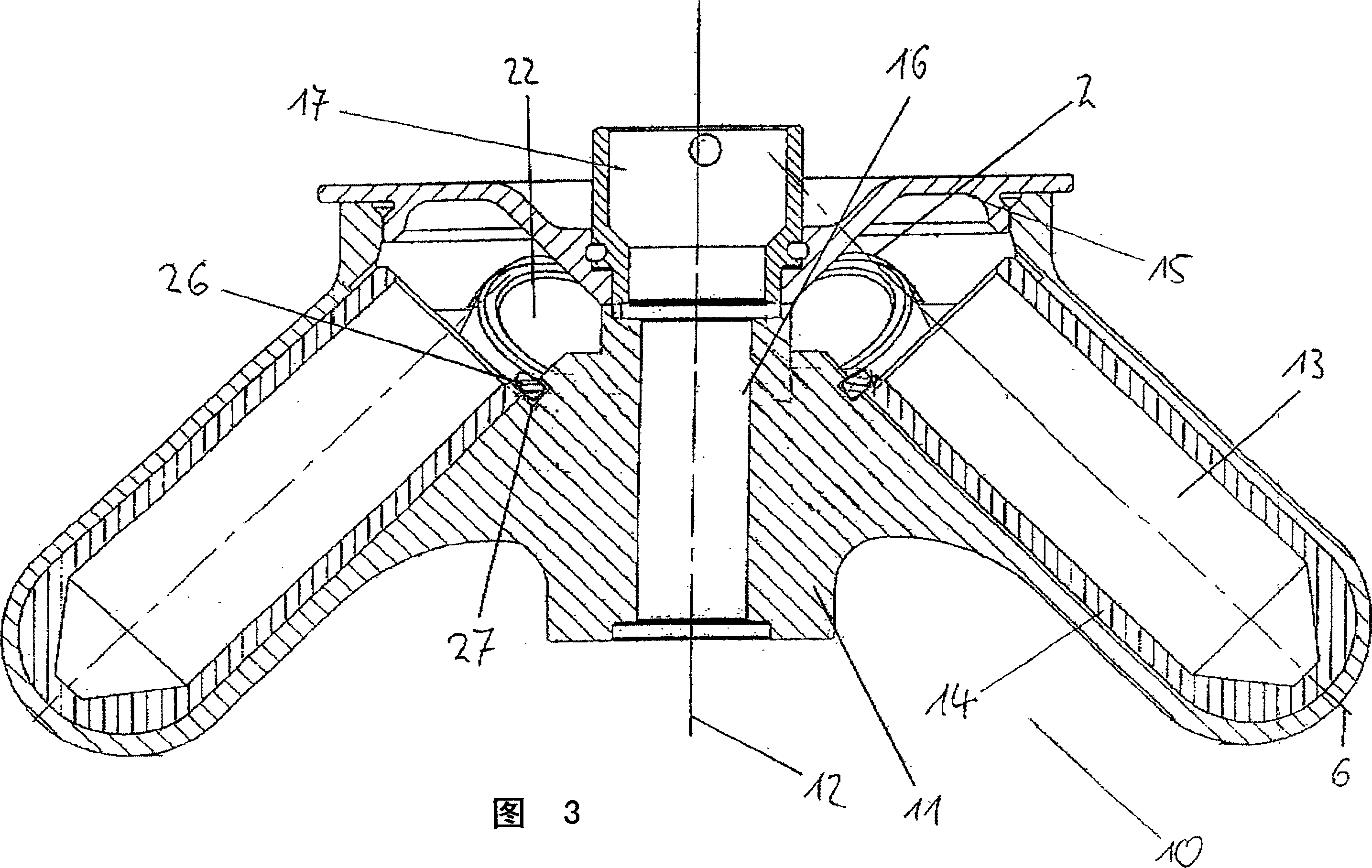

[0047] figure 1 is the cross-section of the rotor 10 of the laboratory centrifuge. The rotor 10 has a frusto-conical shape with a rotor body 11 which is frusto-conical upwards. Annular grooves 13 , surrounding the rotor shaft 12 , are arranged in the outer area of the rotor 10 . In the annular groove 13 , adapters are arranged at regular intervals in the circumferential direction, designed to accommodate the sample containers 5 . The sample container 5 has a cover 3 at its upper end and contains a sample solution 4 .

[0048] The adapter 14 is generally designed as a hollow cylinder with a closed bottom and an opening on the upper end. The outer wall of the annular groove has arcuate recesses 2 designed to receive one adapter 14 each in a positive fit and to fix the adapters 14 in the circumferential direction. The adapter 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com