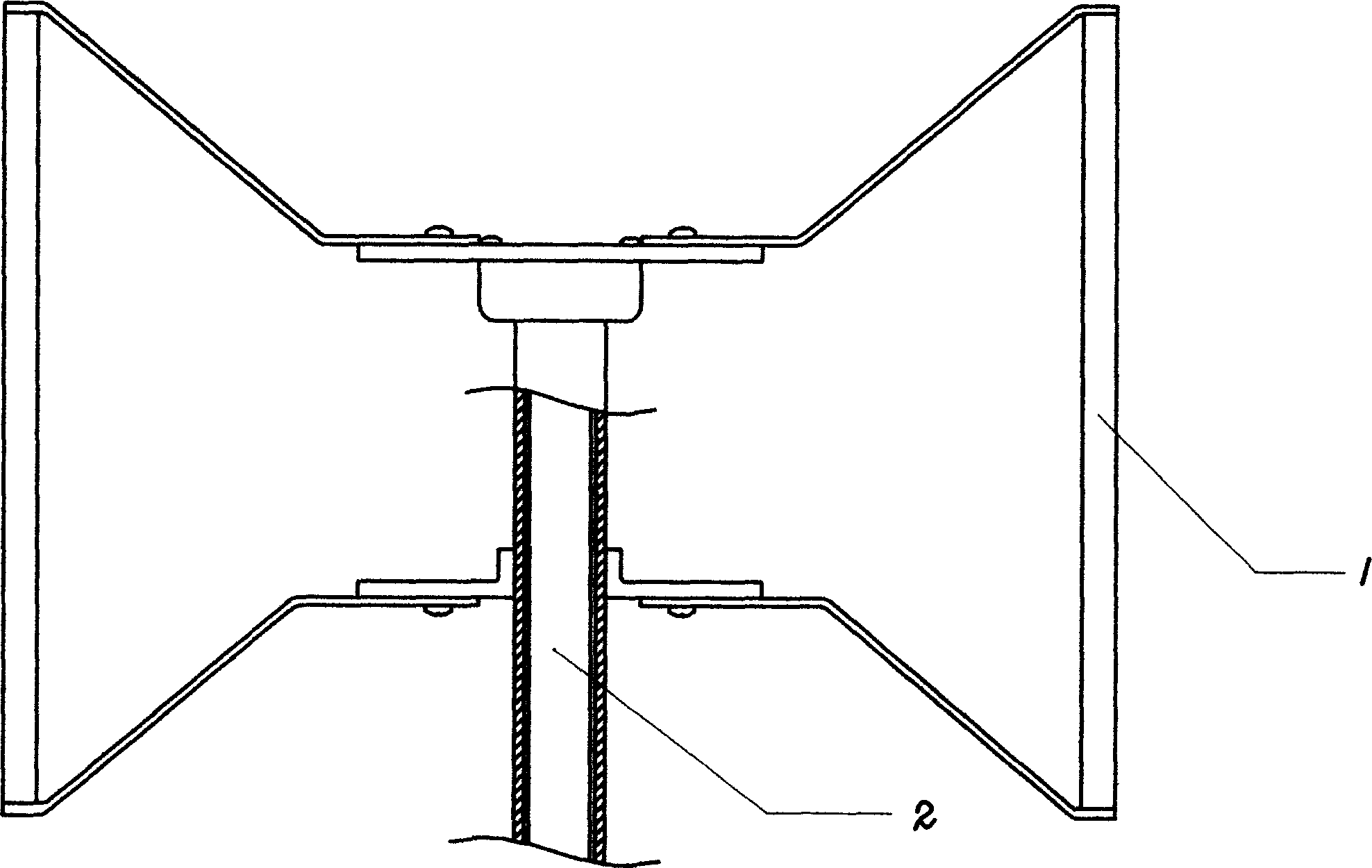

Mounting method for blade of vertical axle wind-mill generator

一种风力发电机、叶片安装的技术,应用在风力发电机组件、风力发动机、与风向成直角的风力发动机等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

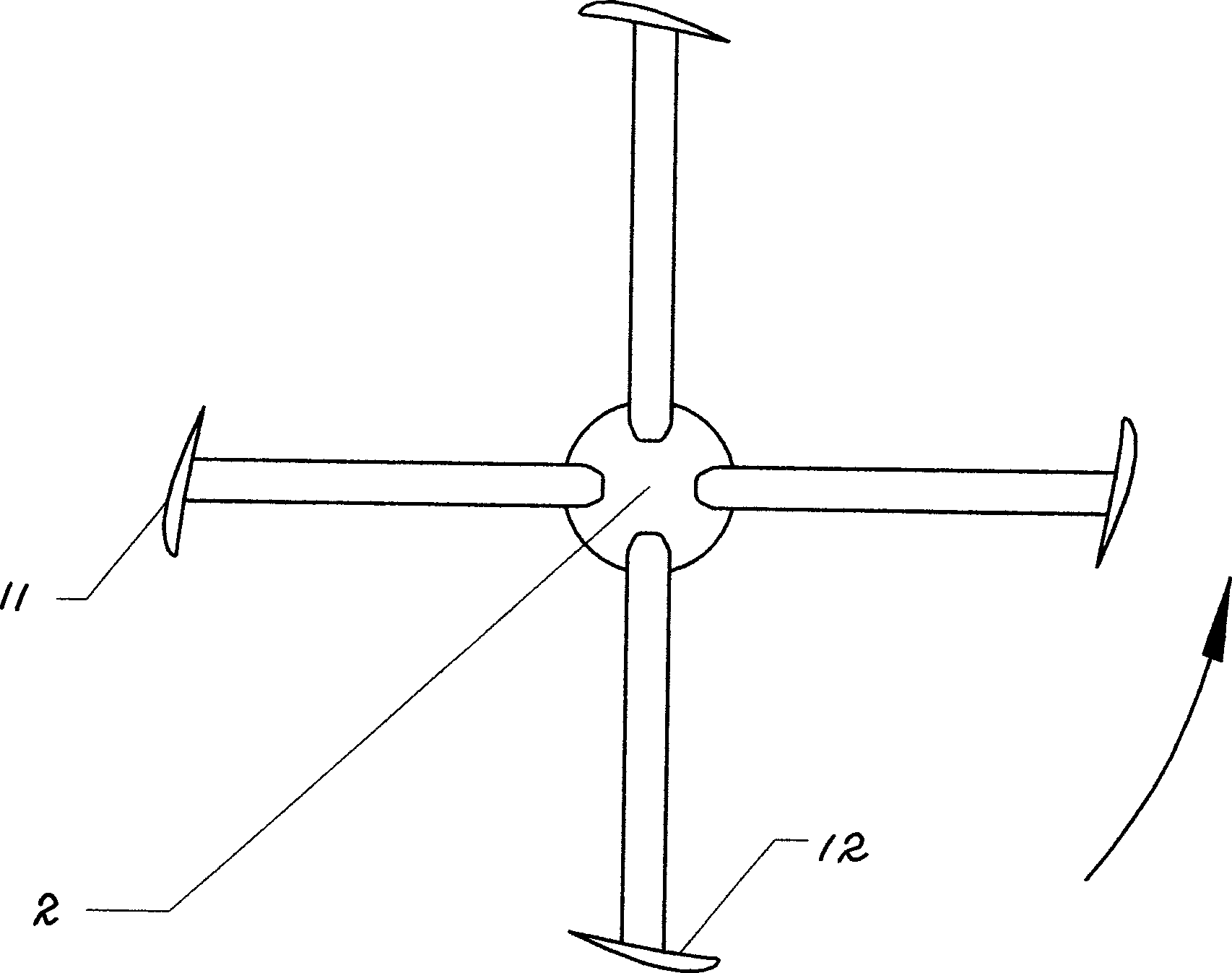

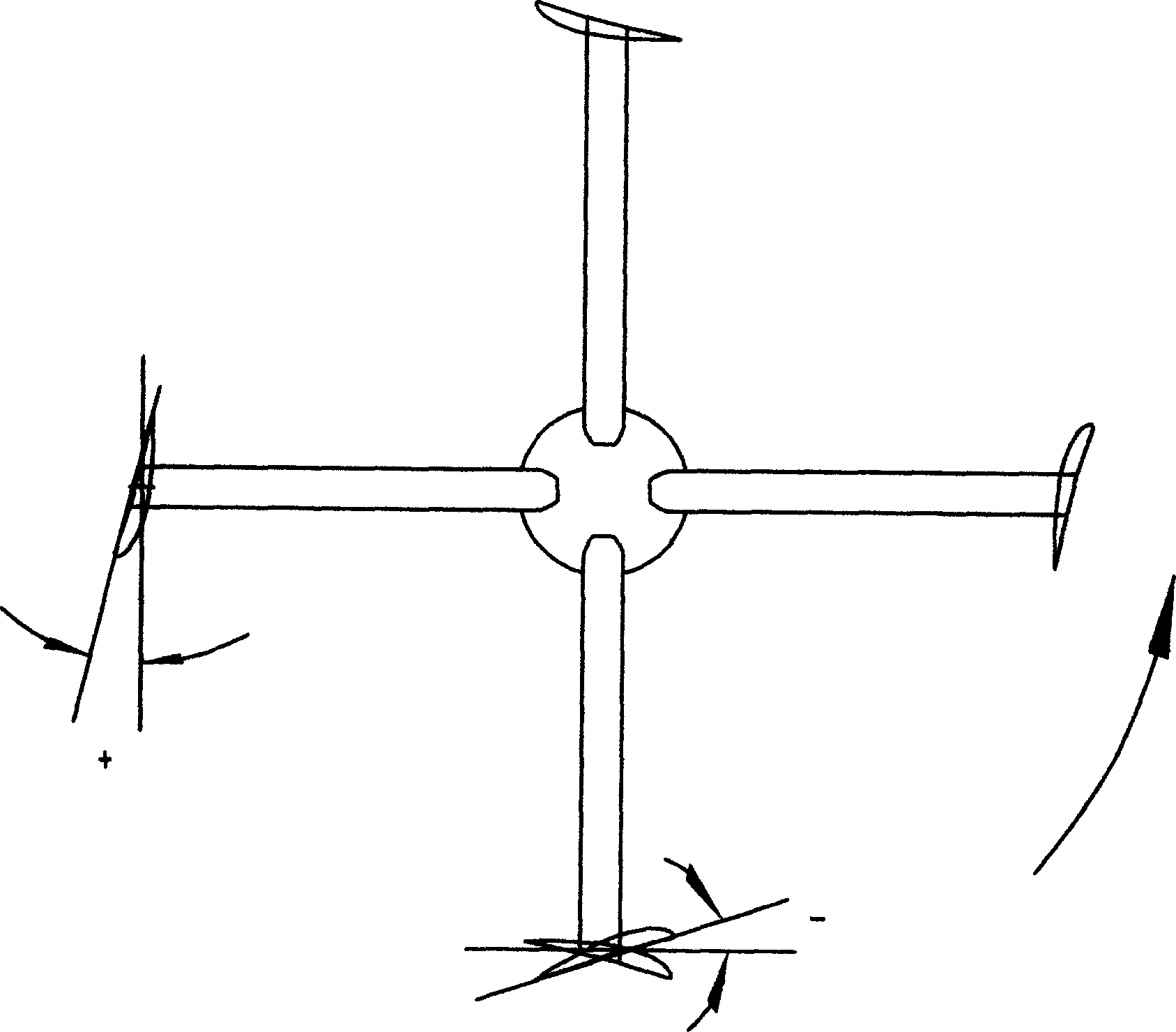

[0023] Taking the standard blade airfoil GOE573, GOE630, GOE364, GOE436, GOE118, GOE147 as an example, the supporting wing is connected to the vertical axis, the blade is installed on the supporting wing, and the convex surface of the blade is installed facing the vertical axis. Set the blade rotation angle to 12 degrees.

[0024] Airfoil / azimuth angle

[0025] When the concave surface is installed facing the vertical axis, the other conditions of the test remain unchanged, the wind wheel cannot rotate, and the magnitude of its driving torque cannot be measured.

Embodiment 2

[0027] Choose the Goe 364 type blade in Example 1, the diameter of the wind wheel is 1.36 meters, the length of the blade is 1 meter, and the following fixed blade rotation angles (unit: degree) are set respectively, corresponding to different wind speeds (unit: m / s), and the generator is measured The output power (unit: watts), as shown in the following table.

[0028]

[0029] From the above table and Figure 4 It can be seen that when the blade rotation angle is in the range of 2 to 12 degrees, the wind speed is in the range of 6 to 13 m / s, and the output power is 9 to 360 watts, which has an ideal output power.

Embodiment 3

[0031] Choose the Goe364 type blade in Example 1, choose the same diameter wind wheel as in Example 2, the same length of the blade and fixed blade corner, under the same wind conditions, only the concave surface 12 facing the vertical axis 2 to install the blade Other experimental conditions are the same as in Example 2. The wind turbine is tested, and the experimental results show that the wind wheel cannot rotate, that is, the generator does not output power at all, which lacks industrial practicability.

[0032] In summary, in a natural environment, a wind speed of 6-13 m / s is an ideal wind speed range for wind energy applications, which shows that the present invention has industrial applicability and creativity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com