Image forming method and image forming apparatus

An image and recording device technology, applied in the direction of printing device, printing, etc., can solve the problem that the surface of the sheet cannot be used, and achieve the effect of effective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

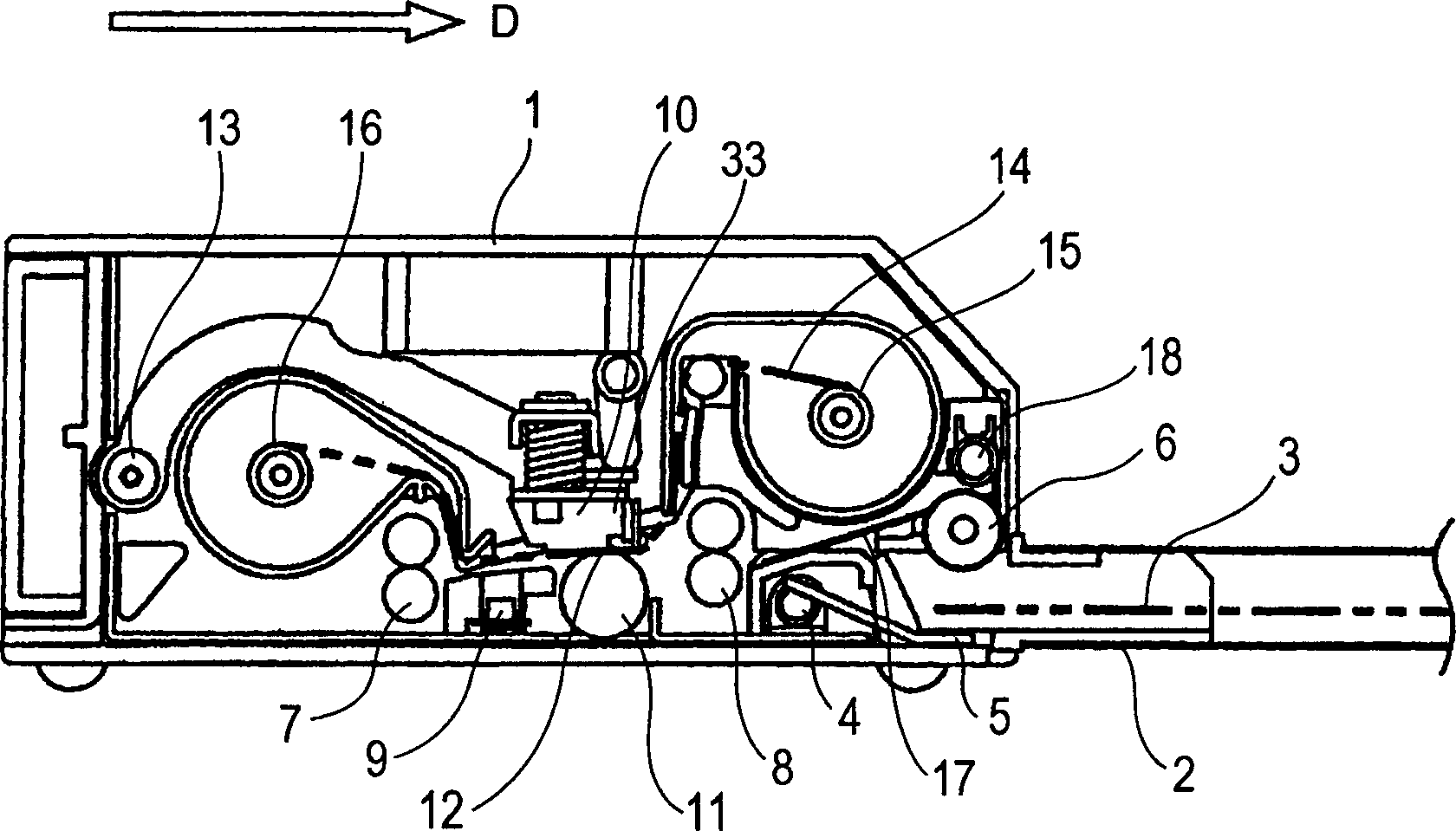

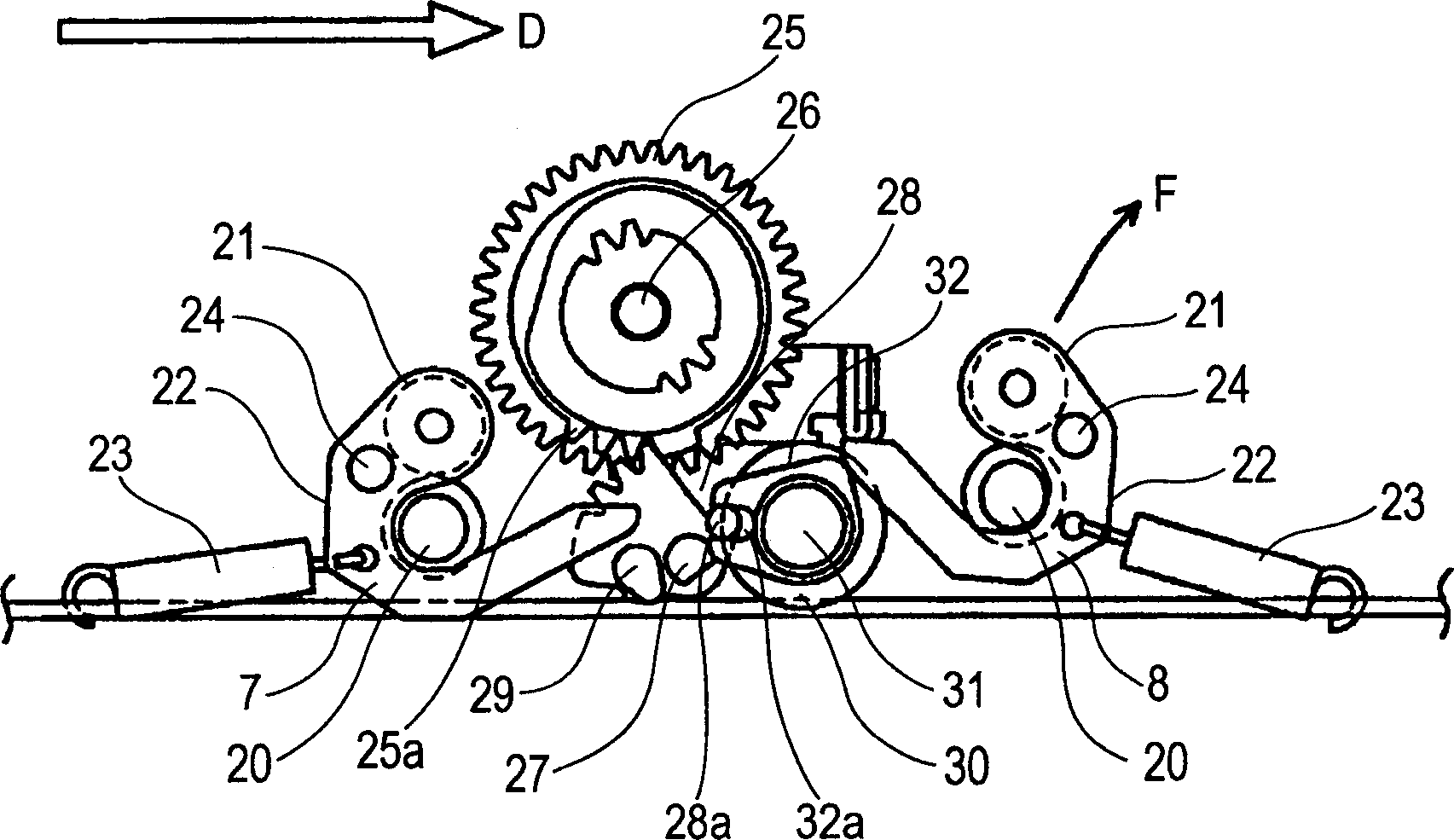

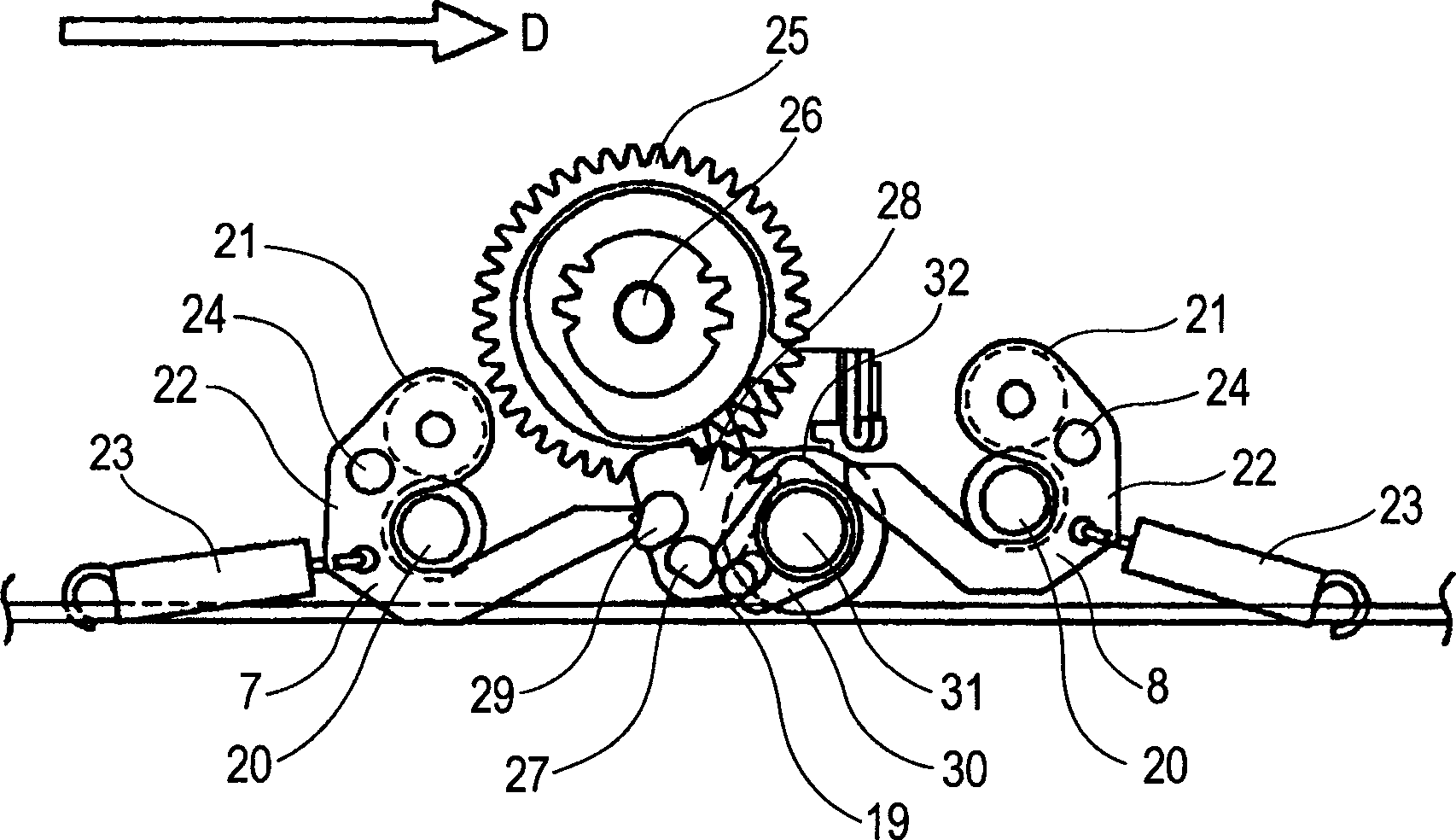

[0025] Now, an image forming method and an image forming apparatus according to an embodiment of the present invention will be described in detail herein with reference to the accompanying drawings.

[0026] figure 1 The main parts of a thermal printer 1 as an example of an image forming apparatus are illustrated. Image information is transmitted from an upper system including a digital device such as a personal computer or a digital camera or a host computer to a control section (not shown) of the thermal printer 1 through, for example, a connecting cable. Upon receiving the image information, the control section starts a recording operation to form an image on the sheet 3 as recording paper.

[0027] Sheets 3 accommodated in paper feed tray (feeding section) 2 are pressed against feed rollers 6 by upper / lower plates 5 that swing up and down about upper / lower plate shafts 4 . The rotation of the feed roller 6 picks up the sheet 3 . The sheet 3 is then fed into the device b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com