Automatic labeling system and method for hard disk

A label and hard disk technology, applied in the system field of labeling on the hard disk, can solve the problems of increasing the labor intensity of employees, increasing the number of operators, reducing production efficiency, etc., and achieving the effect of reducing manpower, reducing labor intensity and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

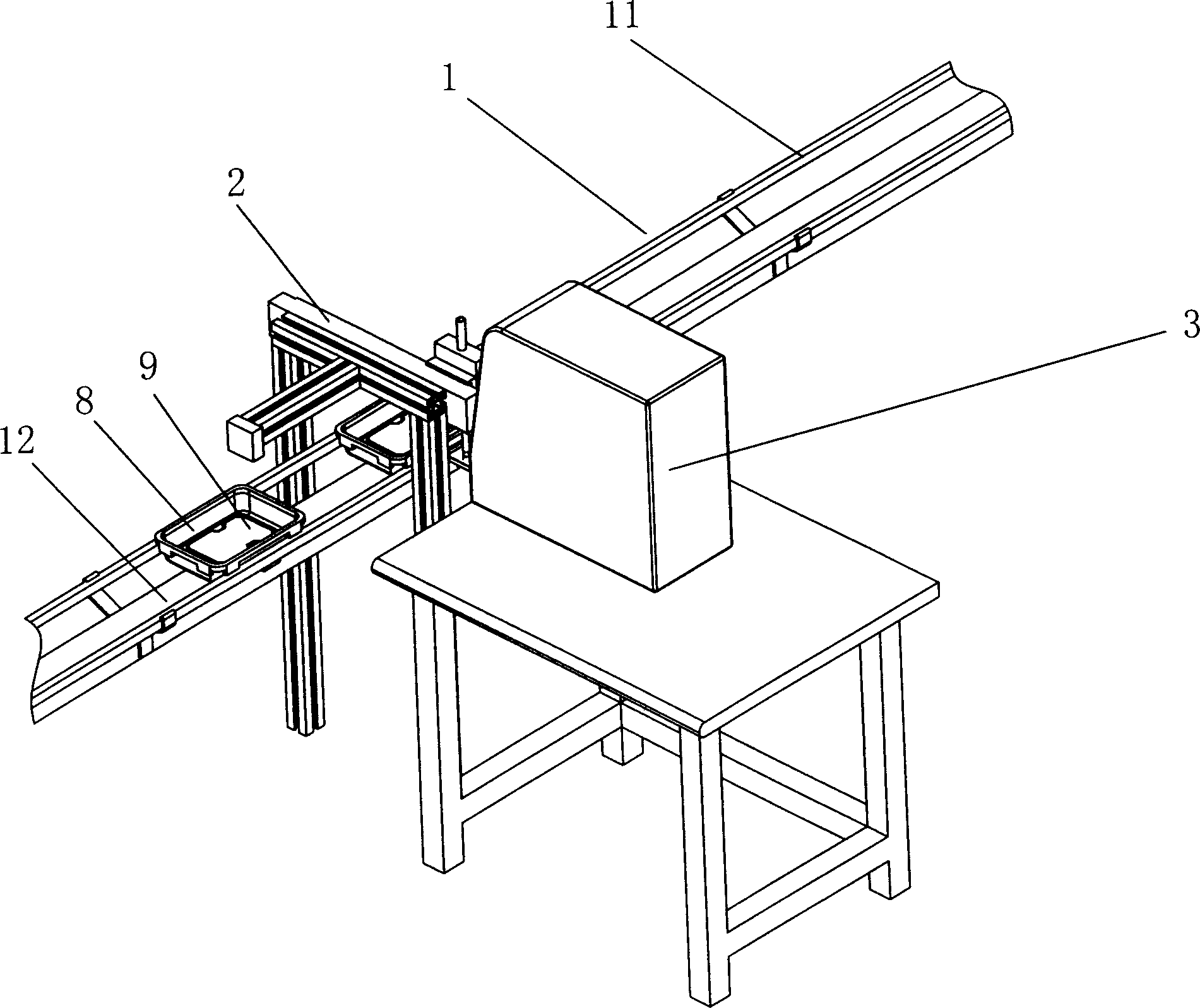

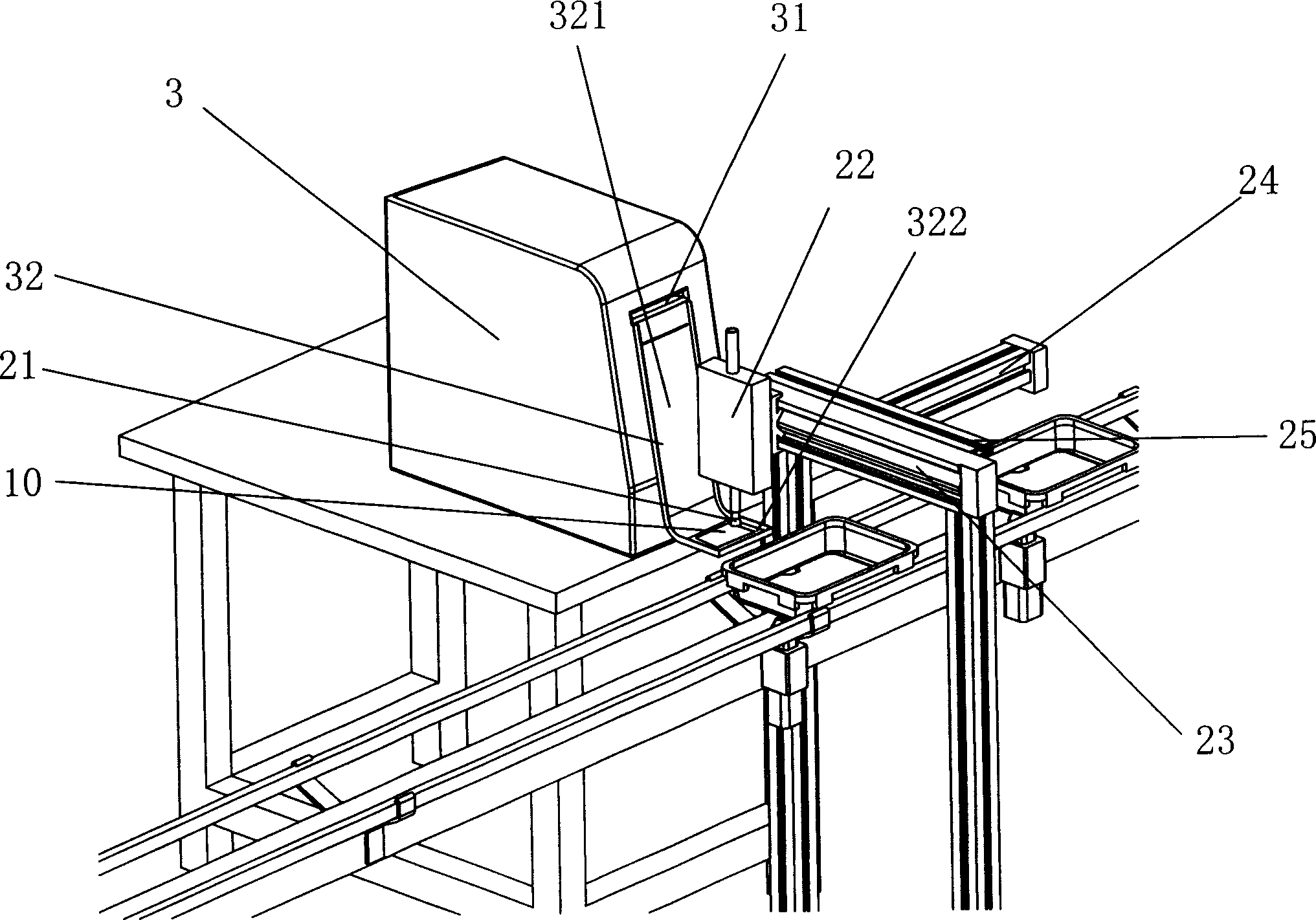

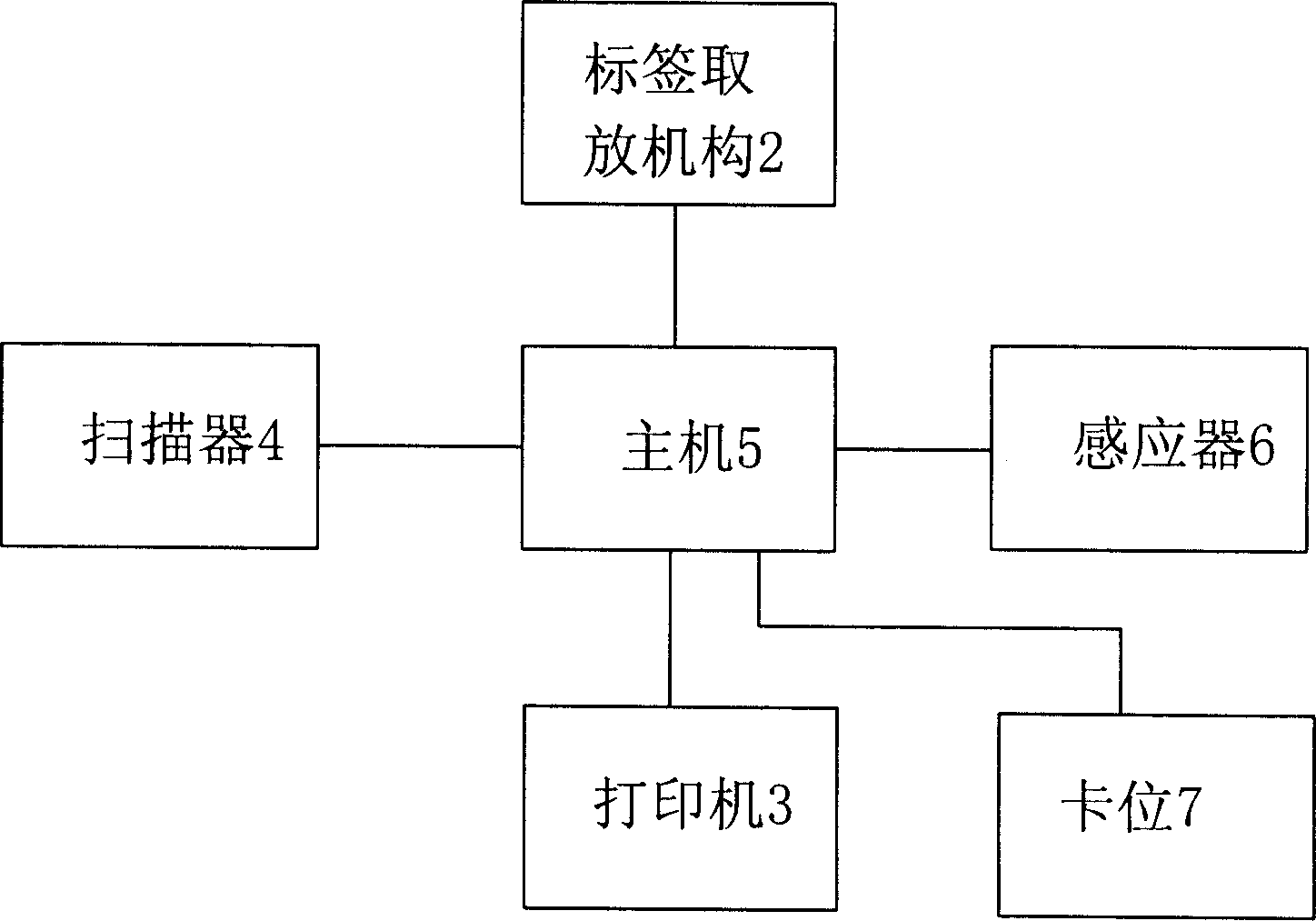

[0019] see Figure 1 to Figure 3 , The hard disk labeling system of the present invention includes a transport mechanism 1 , a label pick-and-place mechanism 2 , a printer 3 , a scanner 4 and a host computer 5 . The conveying mechanism 1 is used to convey the hard disk 9 placed in the tray 8, the label pick-and-place mechanism 2 is used to automatically pick and place the label 10, the printer 3 is used to print the label 10, and the scanner 4 is used to scan the hard disk 9 for identification For barcodes, the host computer 5 is used to coordinate and control the label pick-and-place mechanism 2 , printer 3 and scanner 4 .

[0020] Transmission mechanism 1 comprises conveyor belt support 11, conveyor belt 12 and drive motor, and this conveyor belt support 11 is fixedly arranged on the ground, and conveyor belt 12 is installed on this conveyor belt support 11, and it is driven by motor and realizes the delivery to hard disk 9.

[0021] The label pick-and-place mechanism 2 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com