Cylindrical cell and manufacturing method thereof

A technology of cylindrical battery and manufacturing method, applied in the direction of battery pack components, circuits, electrical components, etc., capable of solving problems such as high connection resistance, battery voltage drop, breakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

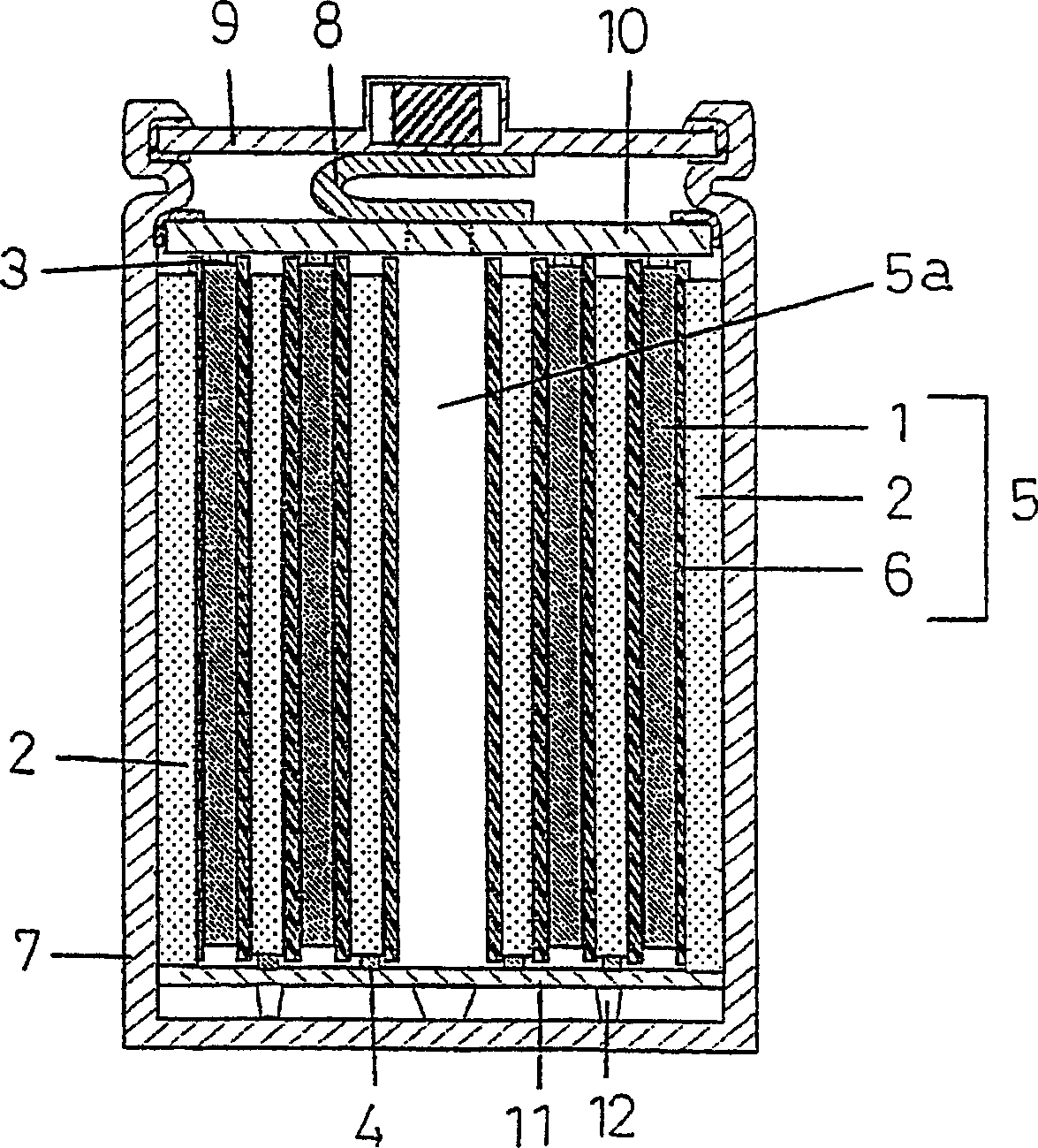

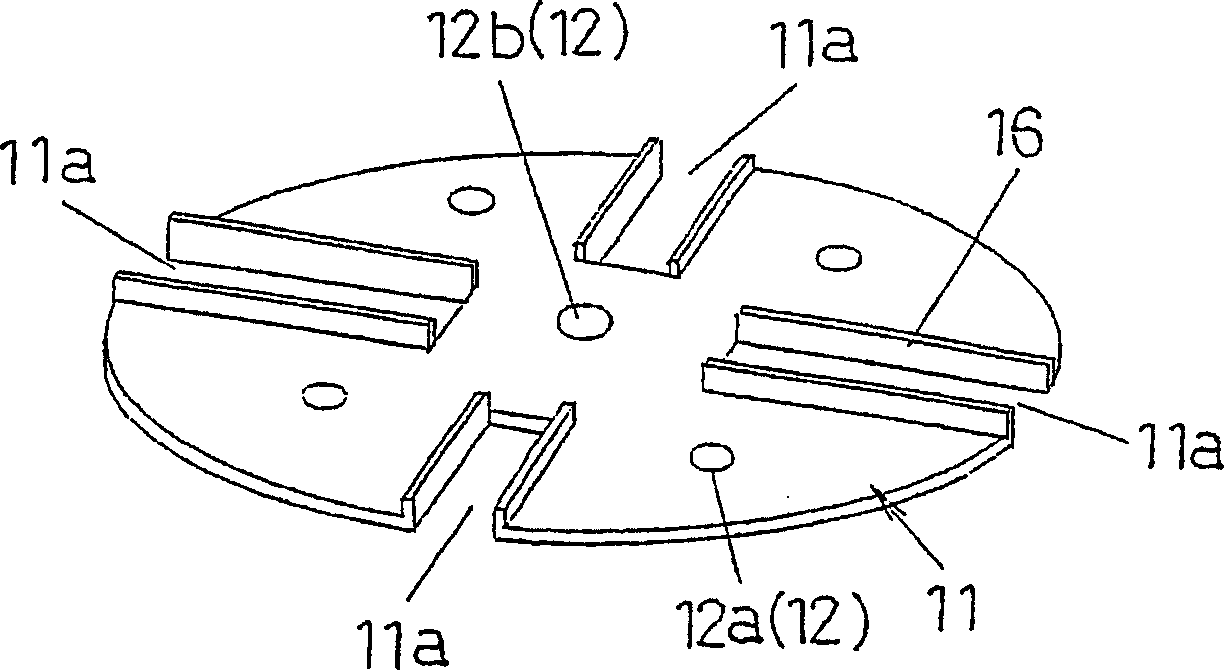

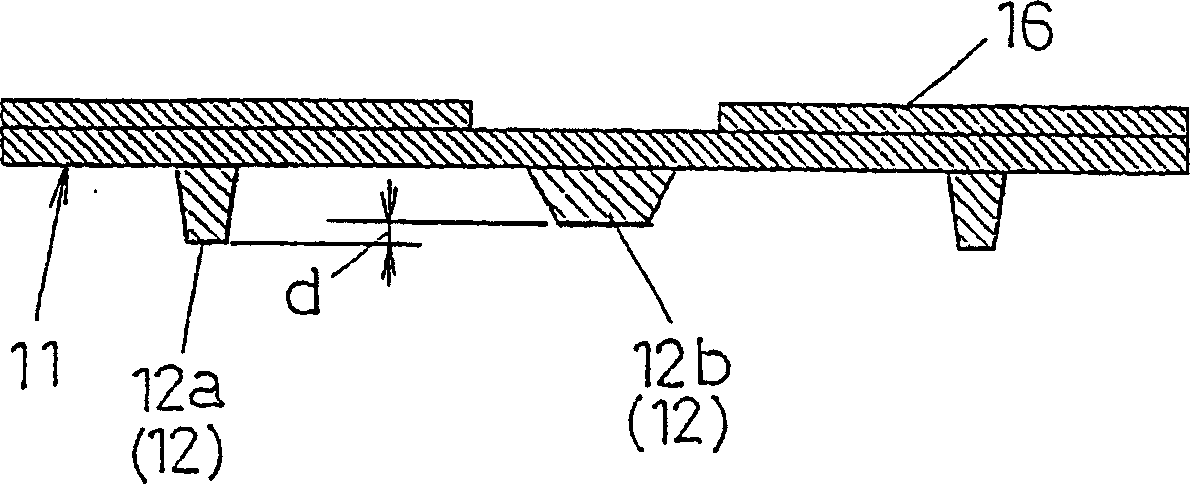

[0028] First, refer to Figure 1 to Figure 7 The cylindrical battery and its manufacturing method according to the first embodiment of the present invention will be described.

[0029] figure 1 It is a schematic sectional view of the cylindrical battery of this embodiment. exist figure 1Among them, the electrode plate group 5 of the cylindrical battery is formed by winding them in a spiral shape with the strip-shaped separator 6 sandwiched between the strip-shaped positive electrode plate 1 and the strip-shaped negative electrode plate 2 . The core material 3 of the positive electrode plate 1 protrudes above the electrode plate group 5 , and the core material 4 of the negative electrode plate 2 protrudes below the electrode plate group 5 . On the protruding part of the core material 3 of the positive electrode plate 1 protruding above the electrode plate group 5, the positive electrode current collector 10 is welded, and on the protruding part of the core material 4 of t...

no. 2 Embodiment approach

[0040] Next, refer to Figure 8 ~ Figure 10 A cylindrical battery and its manufacturing method according to the second embodiment of the present invention will be described. In addition, the same reference numerals are assigned to the same components as those in the first embodiment, and description thereof will be omitted, and only differences will be mainly described.

[0041] In the above-mentioned first embodiment, the protrusions 12a, 12b are protruded from the lower surface of the negative electrode current collector 11, and are welded to the inner bottom surface of the metal case 7 via the protrusions 12a, 12b. However, in this embodiment, Protrusions 15 ( 15 a , 15 b ) are protruded from the inner bottom surface of the metal case 7 , and are welded to the planar lower surface of the negative electrode current collector 11 .

[0042] exist Figure 8 Among them, on the bottom surface of the metal shell 7, a plurality of protrusions 15a are protruded upward in the area ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com