Automatic roller rack corrector

A technology of roller support and deviation correction device, which is applied in the field of deviation correction devices, and can solve the problems of high cost and complex structure of deviation correction devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

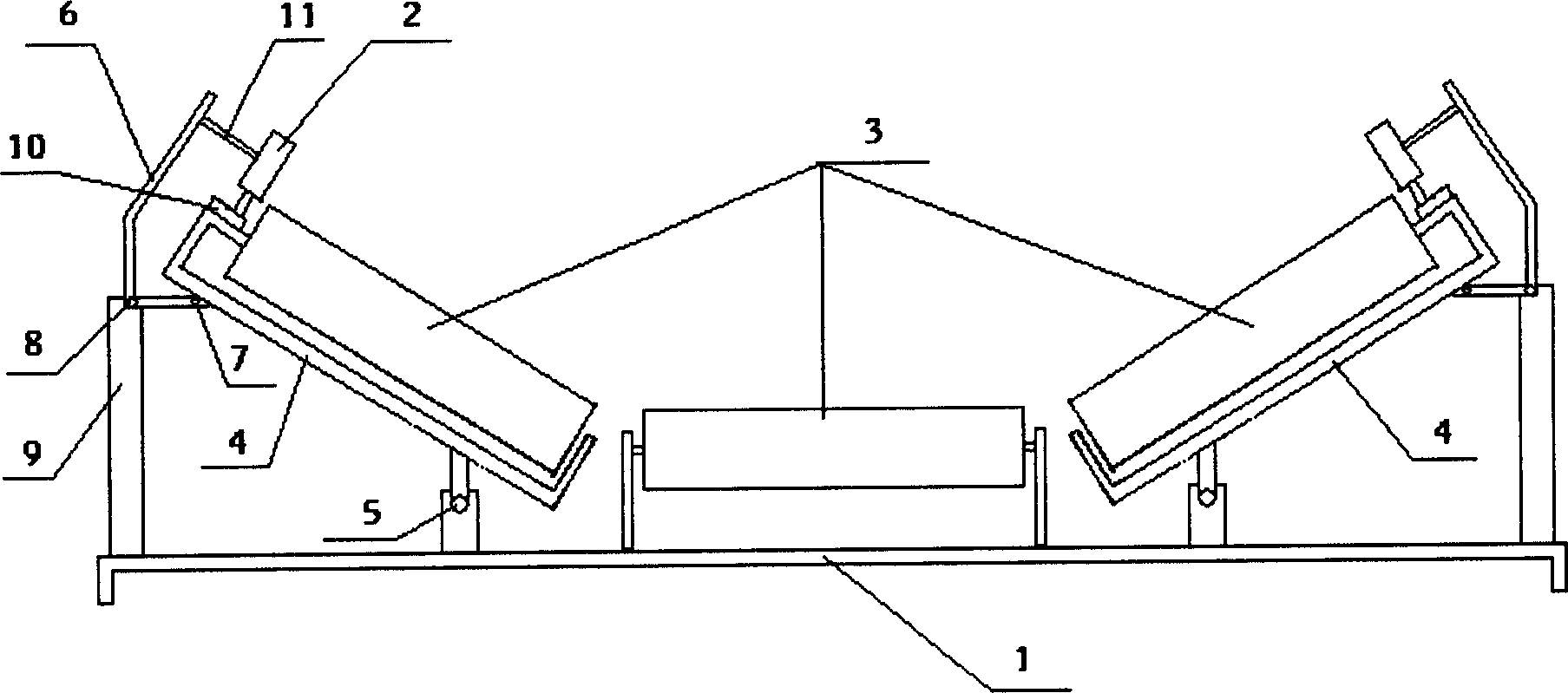

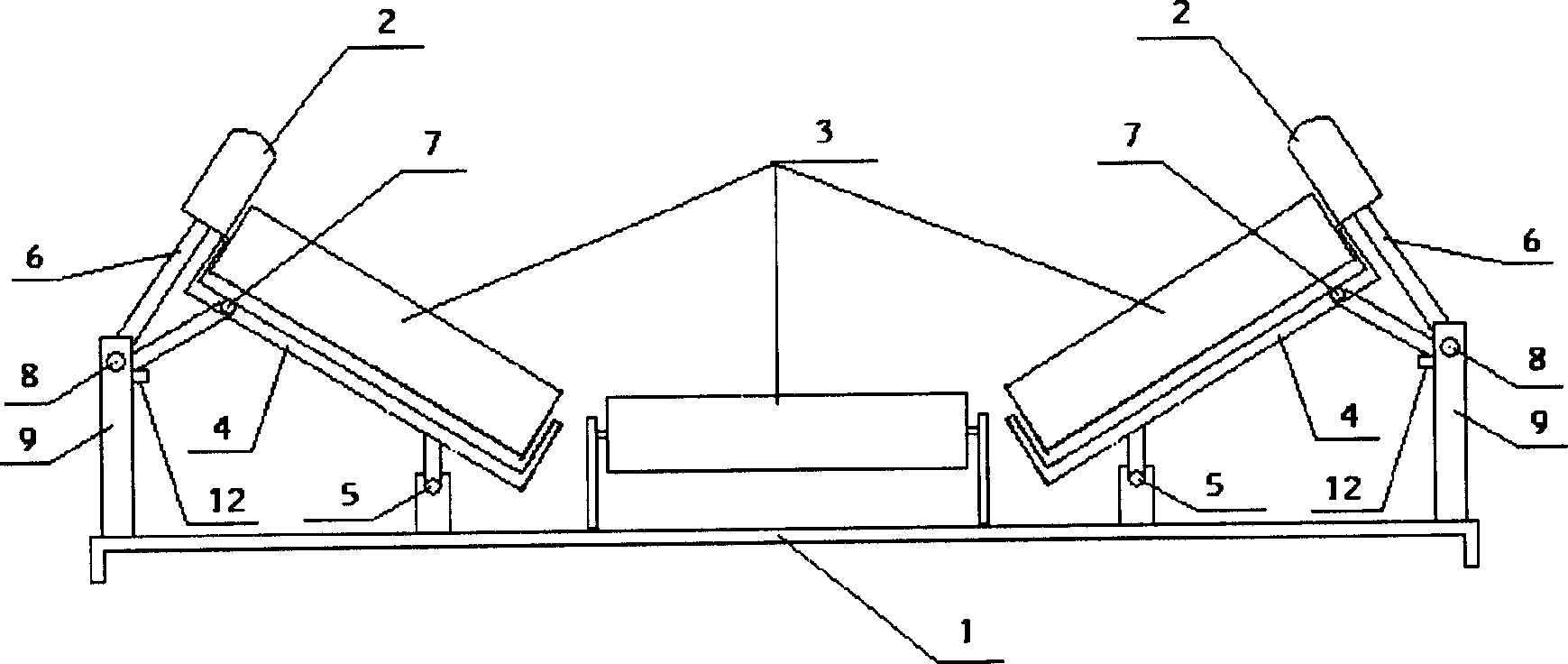

[0016] The first embodiment of the automatic deviation correction device for idler brackets includes a base 1, a vertical roller 2, an idler roll 3 and an idler bracket 4, and the three idlers 3 are supported by three independent idler brackets 4; The inner ends of the roller brackets 4 on both sides are connected to the base 1 through the rotating pair 5, and the correction device also includes a vertical roller track frame 10 and a crank arm 6, and the vertical roller track frame 10 is installed on both sides On the roller bracket 4, the vertical roller 2 is installed in the vertical roller track frame 10, and the vertical roller 2 can move along the vertical roller track; one end of the crank arm 6 is connected with the vertical roller 2, and the other One end is connected with the outer end of the idler bracket 4, the inflection point of the crank arm 6 is connected with the crank shaft base 9 through the crank shaft 8, the crank shaft base 9 is fixed on the base 1, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com